Flame-resistant polycarbonate moulding compounds for extrusion applications

A molding composition, polycarbonate technology, applied in the field of polycarbonate composition, can solve the problem of weak thermal shape invariance and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

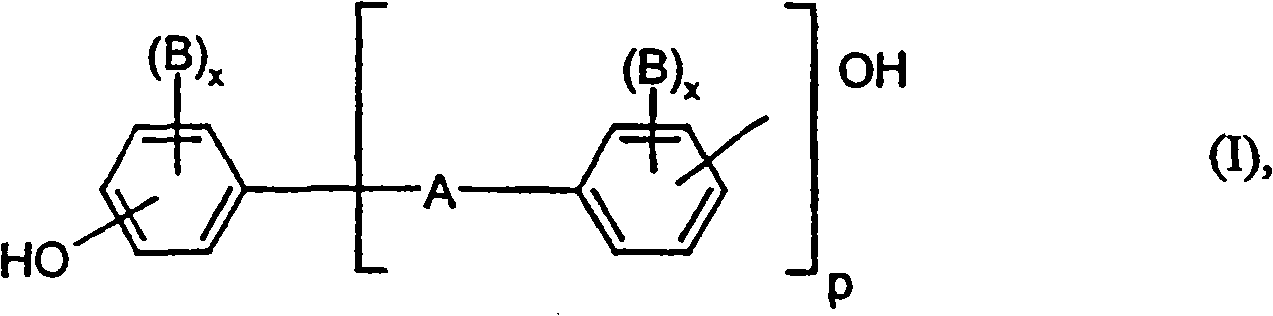

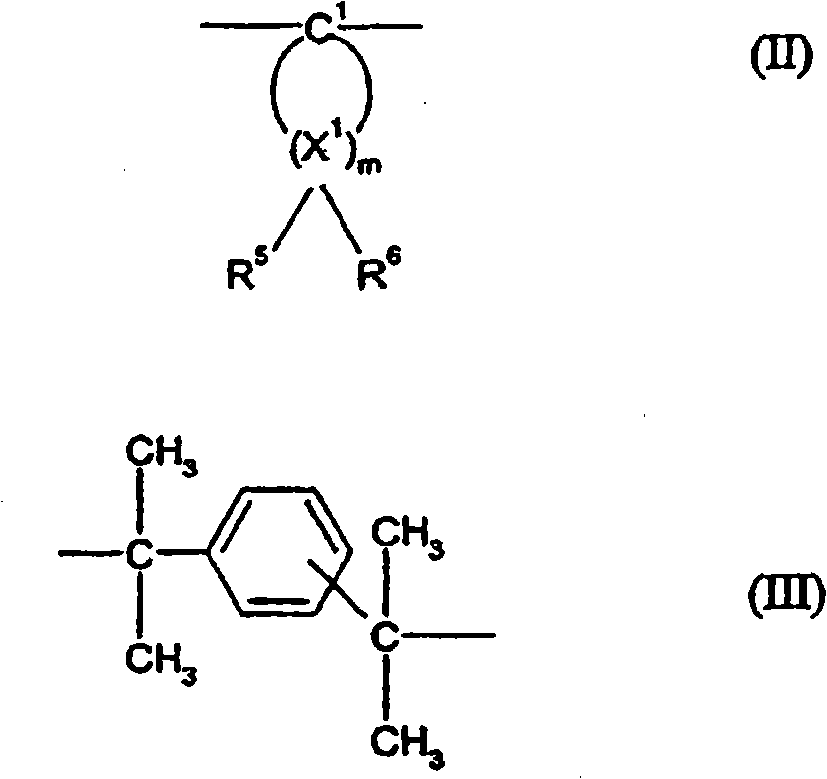

[0190] Component A

[0191] The branched polycarbonate based on bisphenol A has a relative solution viscosity of 1.34 measured in dichloromethane at 25° C. and a concentration of 0.5 g / 100 ml.

[0192] Component B

[0193] 45 parts by weight of styrene and acrylonitrile in a ratio of 72:28 and 55 parts by weight of granular cross-linked polybutadiene rubber (average particle diameter d 50 = 0.3-0.4 μm) graft polymer prepared by emulsion polymerization.

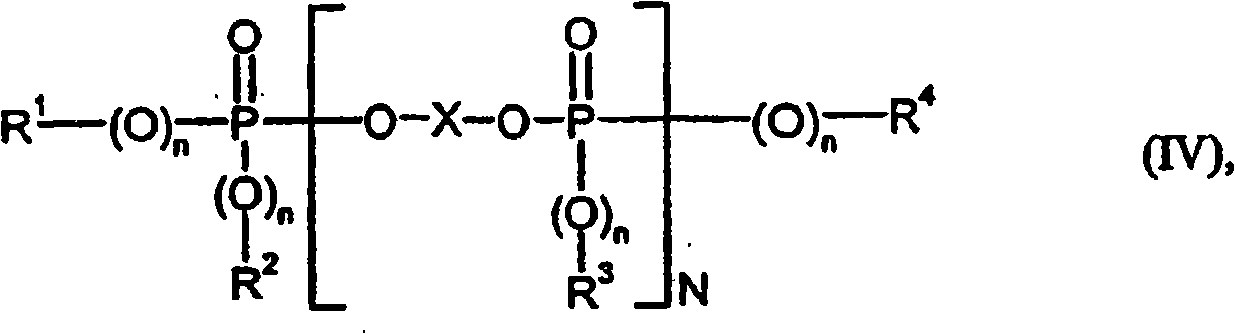

[0194] Component C.1

[0195] Bisphenol-A based oligophosphate

[0196]

[0197] Component C.2

[0198] Resorcinol-based oligophosphates

[0199]

[0200] In order to determine the number-average N-values of the given components C.1 and C.2, the content of oligomeric phosphate esters was first determined by HPLC measurement:

[0201] Column type: LiChrosorp RP-8

[0202] Eluent in gradient elution: acetonitrile / water 50:50-100:0

[0203] Concentration: 5mg / ml

[0204] The weight-averaged N average value...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com