Explosive forming method of arc-wave titanium anode plate

A titanium anode plate, explosive forming technology, applied in the direction of electrode, electrode shape/type, electrolysis process, etc., can solve the problems of low production efficiency and large size, and achieve the effect of improving production efficiency, reducing production cost and improving forming pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Embodiments of the present invention will be specifically described below.

[0012] 1) Select the TA1 grade titanium plate with excellent elongation performance, and its elongation rate is required to be greater than 40%, and at the same time strictly check the surface for no defects.

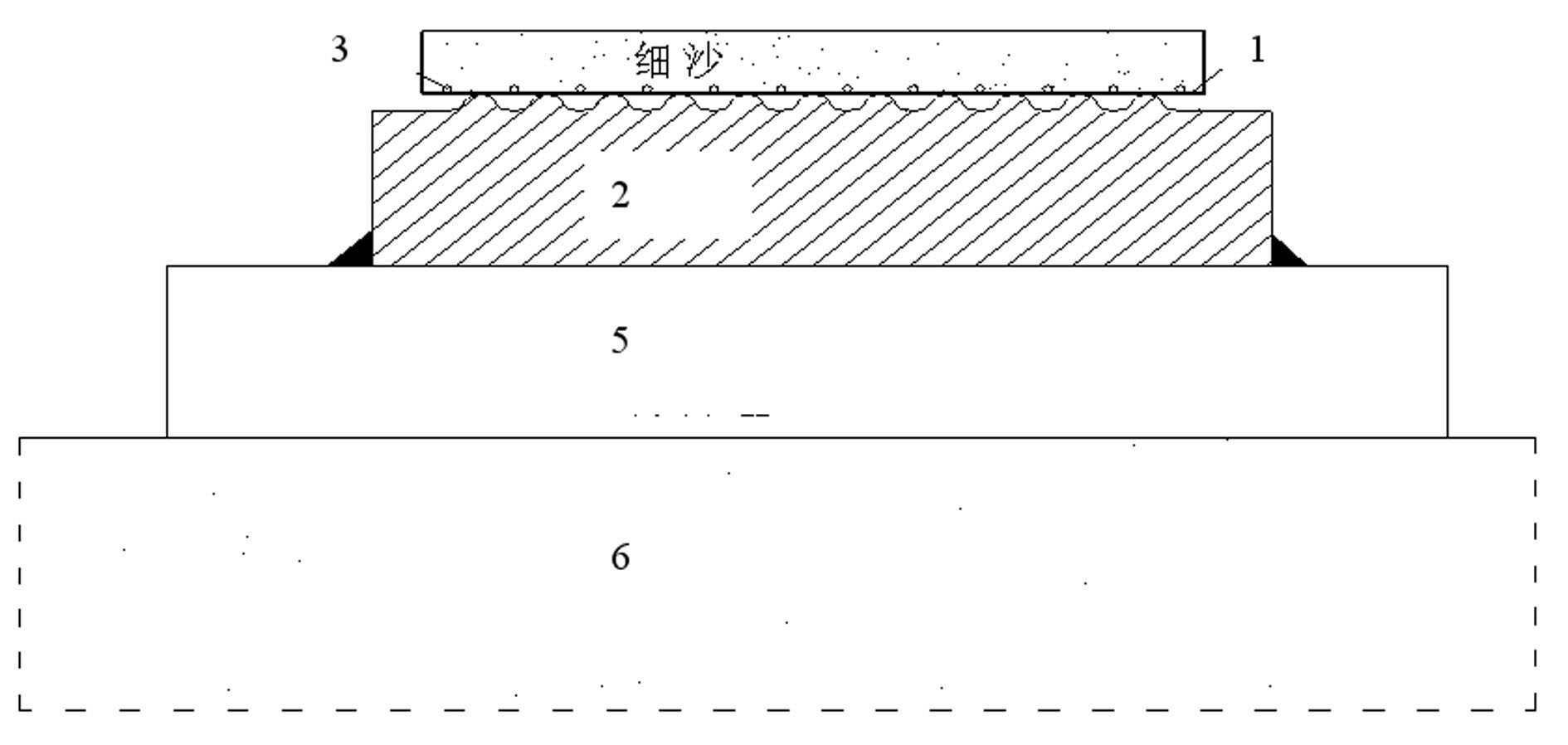

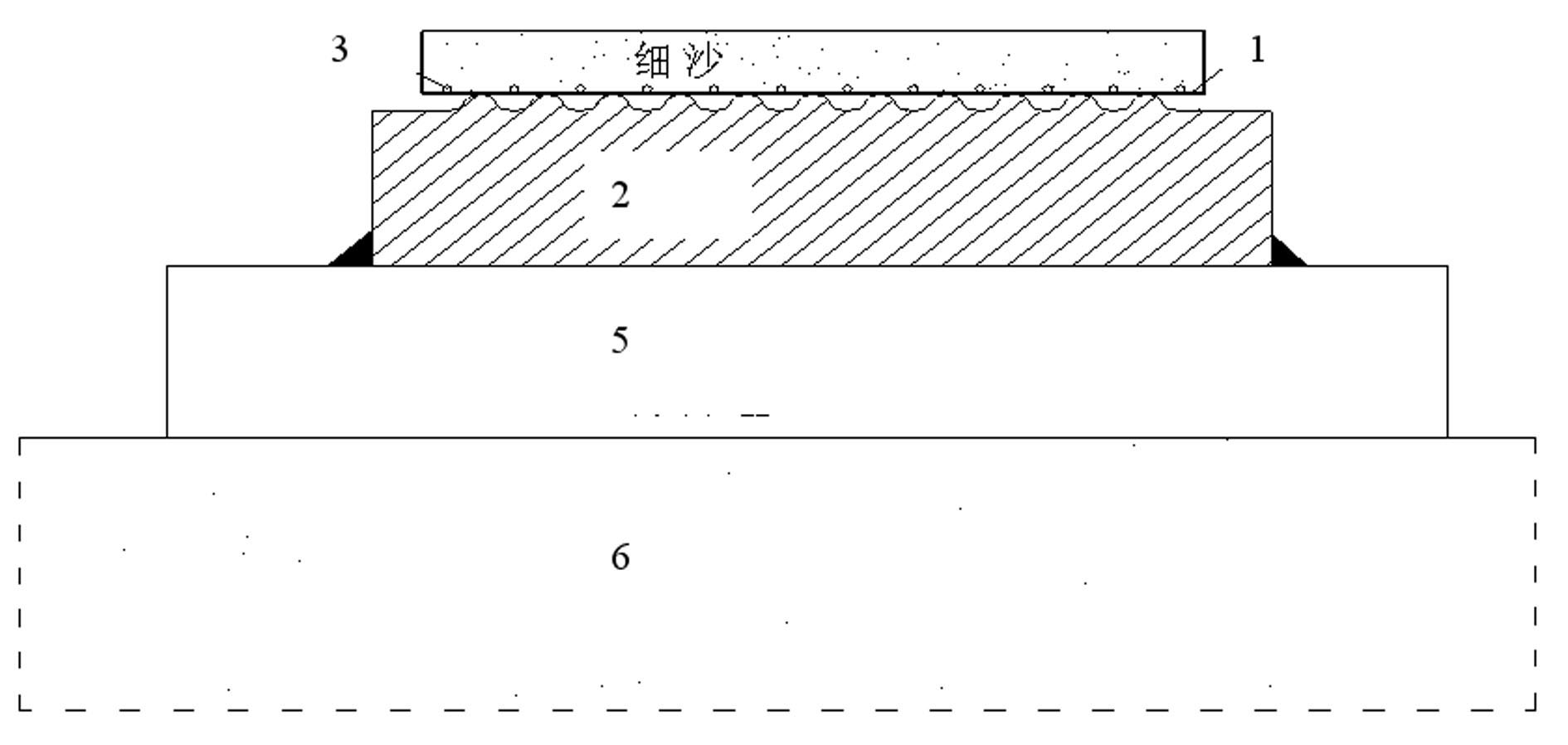

[0013] 2) Process the mold according to the shape of the required titanium anode plate. The mold is welded and fixed on the thick base plate.

[0014] 3) Apply butter on the surface of the titanium plate blank as an explosion protection layer. Place the titanium plate blank on the mold, fix the detonating cord of the expansion tube with tape on the surface of the titanium plate corresponding to the center position of the mold groove (corresponding to the lowest center position of the small corrugation depression of the corrugated plate), and spread fine sand evenly on the titanium plate , The thickness of the fine sand is 30mm~150mm, and it can be packed in bulk, in sand boxes or in sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com