Device for cooling an exhaust gas stream

A technology of exhaust gas flow and exhaust pipe, which is applied in the direction of exhaust device, noise reduction device, exhaust treatment, etc., can solve the problem of increased exhaust gas back pressure, and achieve the effect of simple structure, space saving and avoiding blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

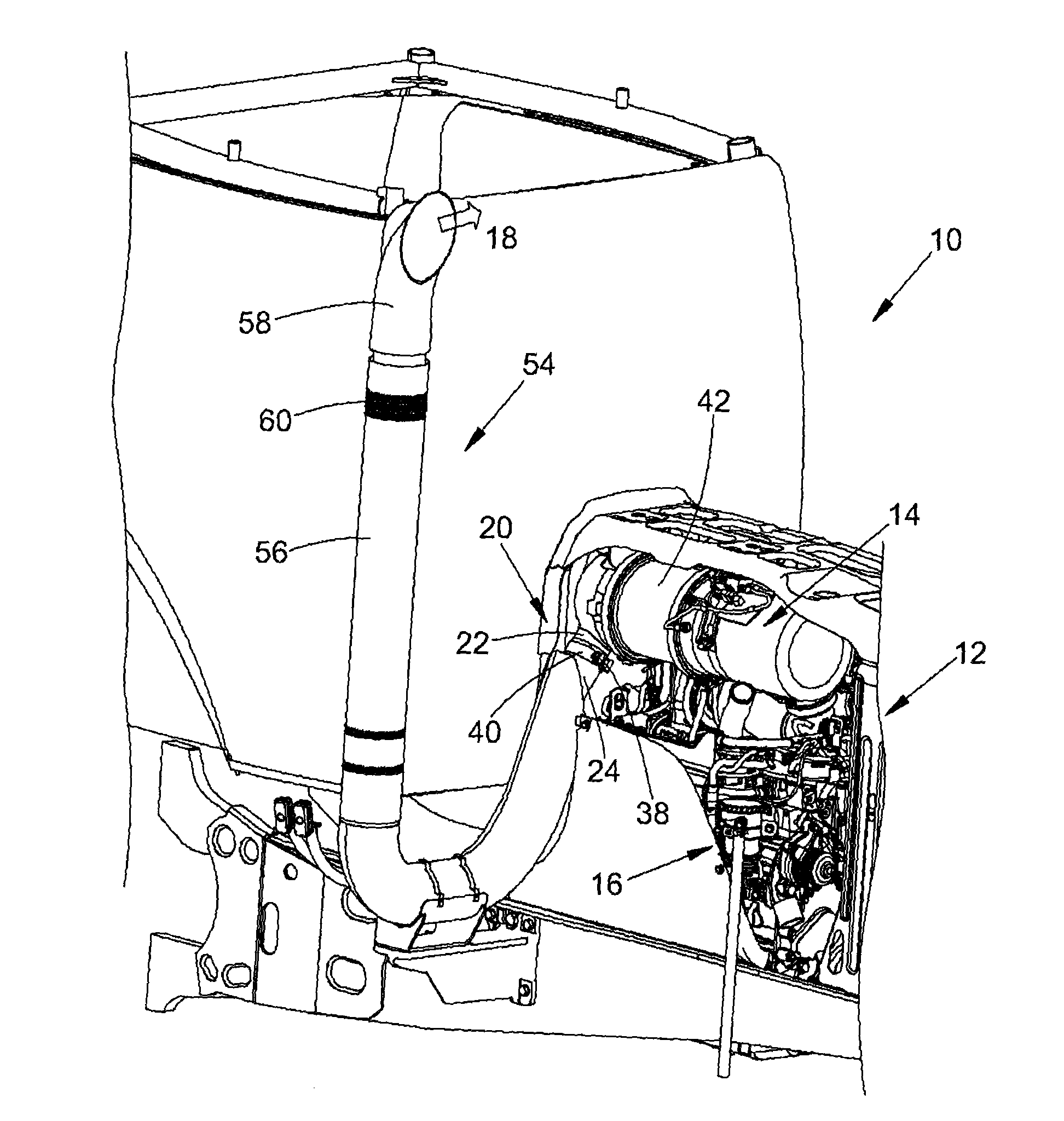

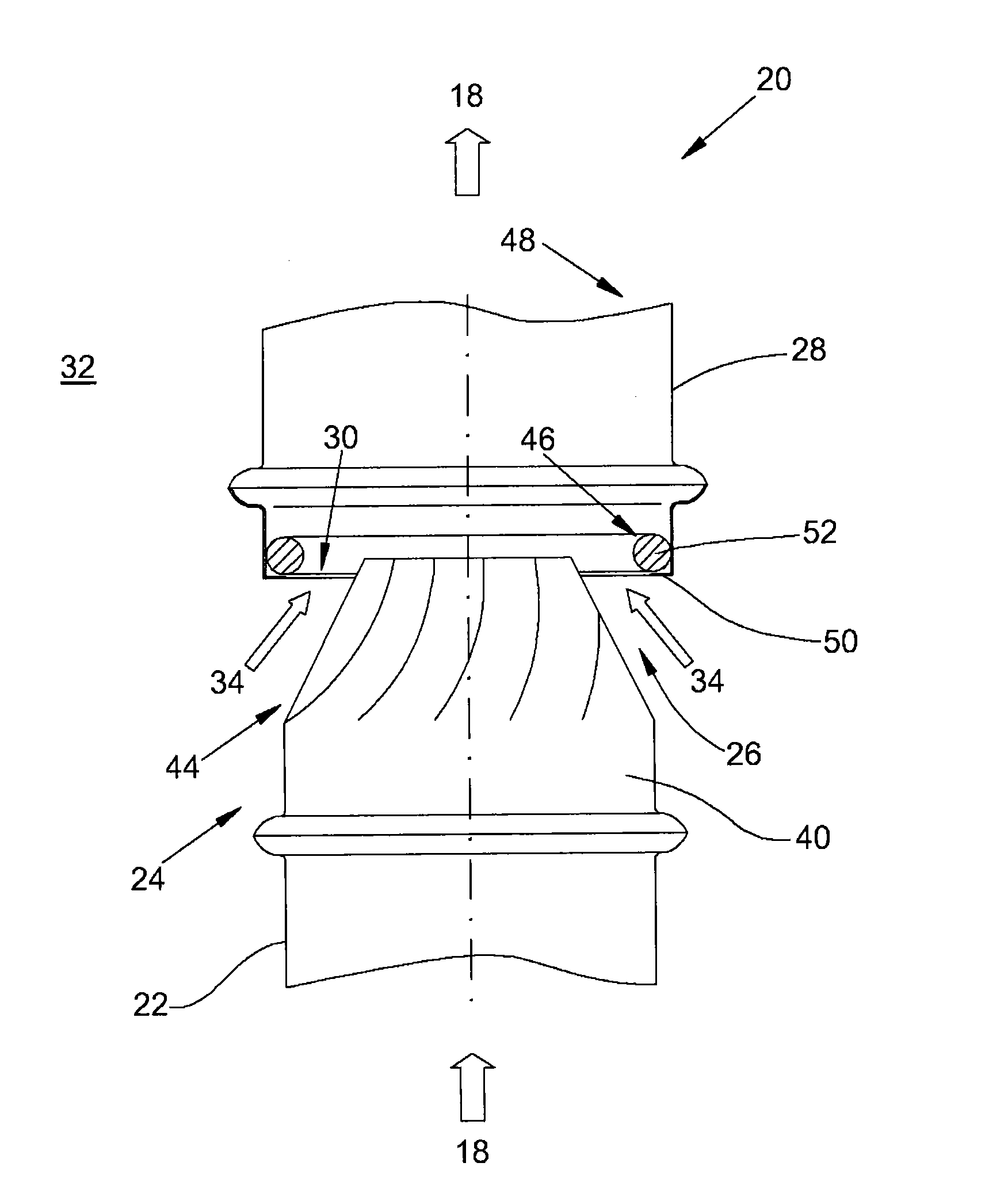

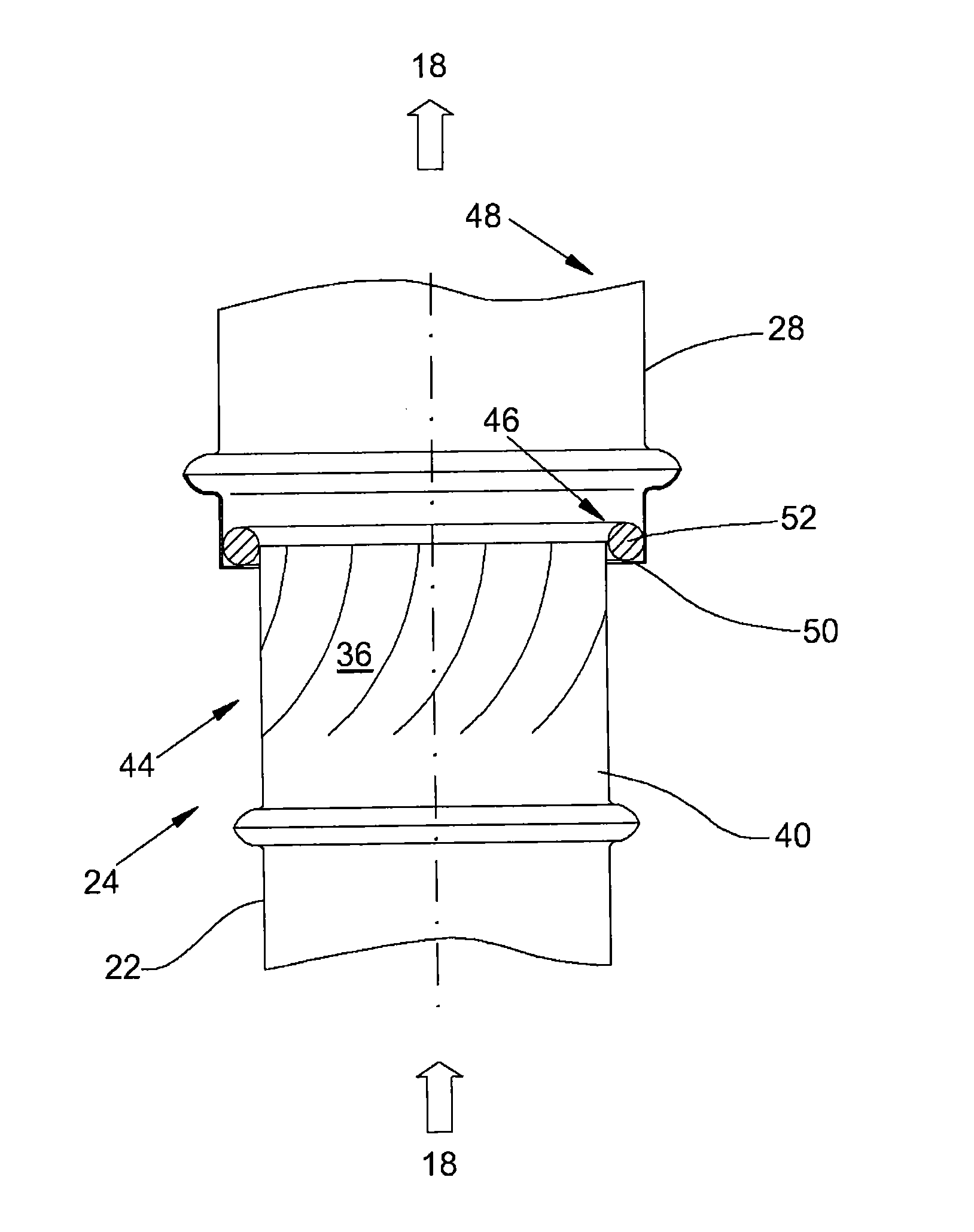

[0022] figure 1 Shows a general perspective view of an embodiment of the device according to the invention for cooling the exhaust gas flow coming out of the soot particle filter on an agricultural production vehicle, wherein figure 2 Or image 3 During the regeneration phase of the carbon black particle filter or in other words outside the regeneration phase of the carbon black particle filter, the operation of the device according to the invention is reproduced. figure 1 A detailed view of the example shown in .

[0023] An agricultural production vehicle 10 configured, for example, as a tractor, includes a soot particulate filter 14 disposed in the engine compartment 12, wherein the soot particulate filter is configured as a conventional wall-flow filter, wherein the diesel engine of the agricultural production vehicle 10 16 Generated engine exhaust passes through porous filter walls made of ceramic or metallic material. Here, the soot particles contained in the engine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com