Tuned mass damper structure for reducing pipeline vibration

A technology for tuning mass damping and dampers, which is applied in the direction of shock absorbers, pipe brackets, shock absorbers, etc., can solve problems such as difficult vibration suppression, and achieve the effects of high reliability, easy implementation, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the drawings and embodiments.

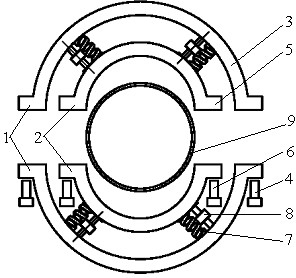

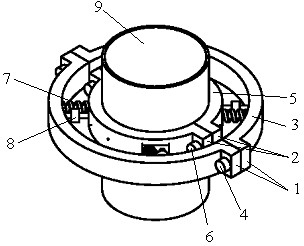

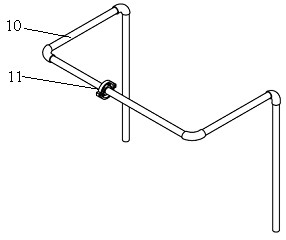

[0020] Such as figure 1 , figure 2 As shown, the present invention includes a whole outer ring 1, a whole inner ring 2, a plurality of springs 7 and the same number of dampers 8 as the springs 7; the whole outer ring 1 is a split structure consisting of two identical and symmetrical half outer rings Ring 3 uses two screws 4 to form a complete outer ring 1; the whole inner ring 2 is also a split structure, and two identical and symmetrical half inner rings 5 are used to form a complete outer ring 2 with the other two screws 6; A combination of four springs and four dampers are installed symmetrically between the outer ring 1 and the entire inner ring 2 in the circumferential direction. The entire outer ring 1 and the entire inner ring 2 form a complete tuned mass damper 11 through multiple sets of springs 7 and dampers 8.

[0021] The inner diameter of the integral in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com