Semiconductor laser device capable of deep cooling and sealing device thereof

A sealing device and laser technology, used in semiconductor lasers, lasers, laser parts and other directions, can solve the problems of easy condensation, high temperature drift, poor cooling capacity, etc., to prevent condensation, avoid temperature drift, and prolong life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

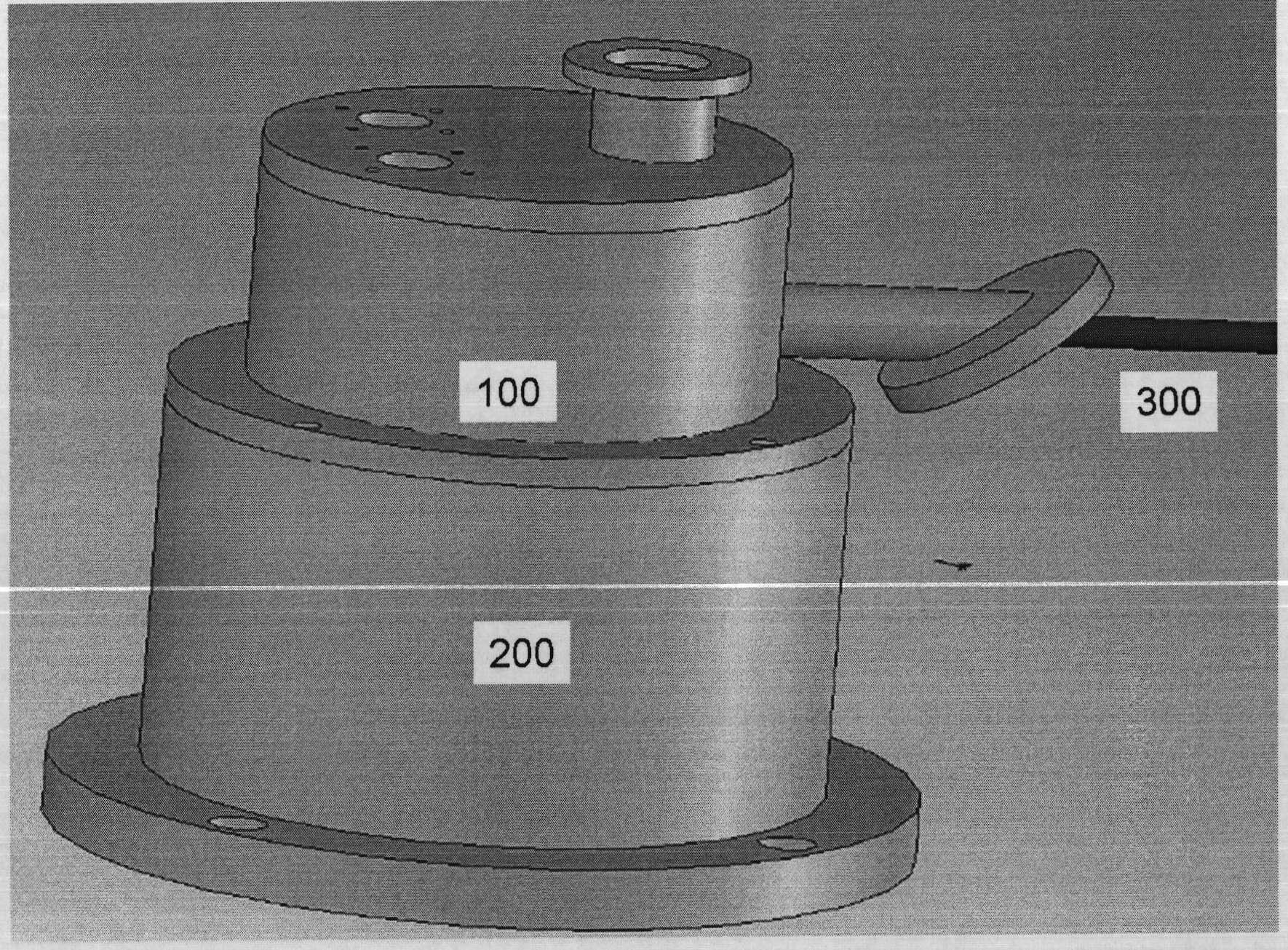

[0027] The sealing device of semiconductor laser according to an embodiment of the present invention, such as figure 1 As shown, it includes two parts, the vacuum cap 100 and the base 200. The vacuum cap 100 and the base 200 can be combined to form a closed cavity. By vacuuming the closed cavity, the semiconductor laser in the closed cavity is in a vacuum. In the environment, the airtight cavity also has a cooling device and an electrical connection device, thereby providing a low-temperature environment and working current for the semiconductor laser. The specific structure of the sealing device will be described in detail below.

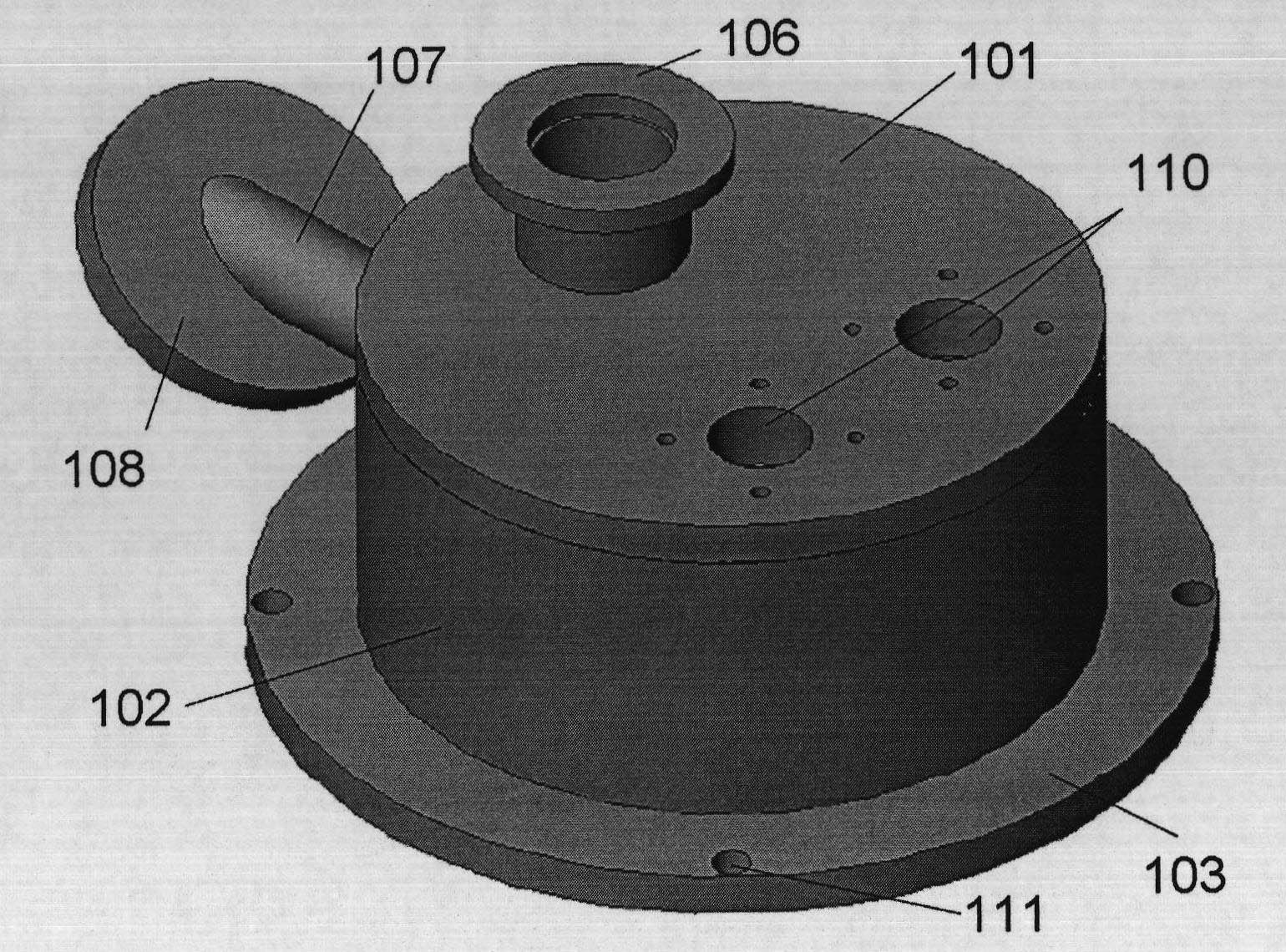

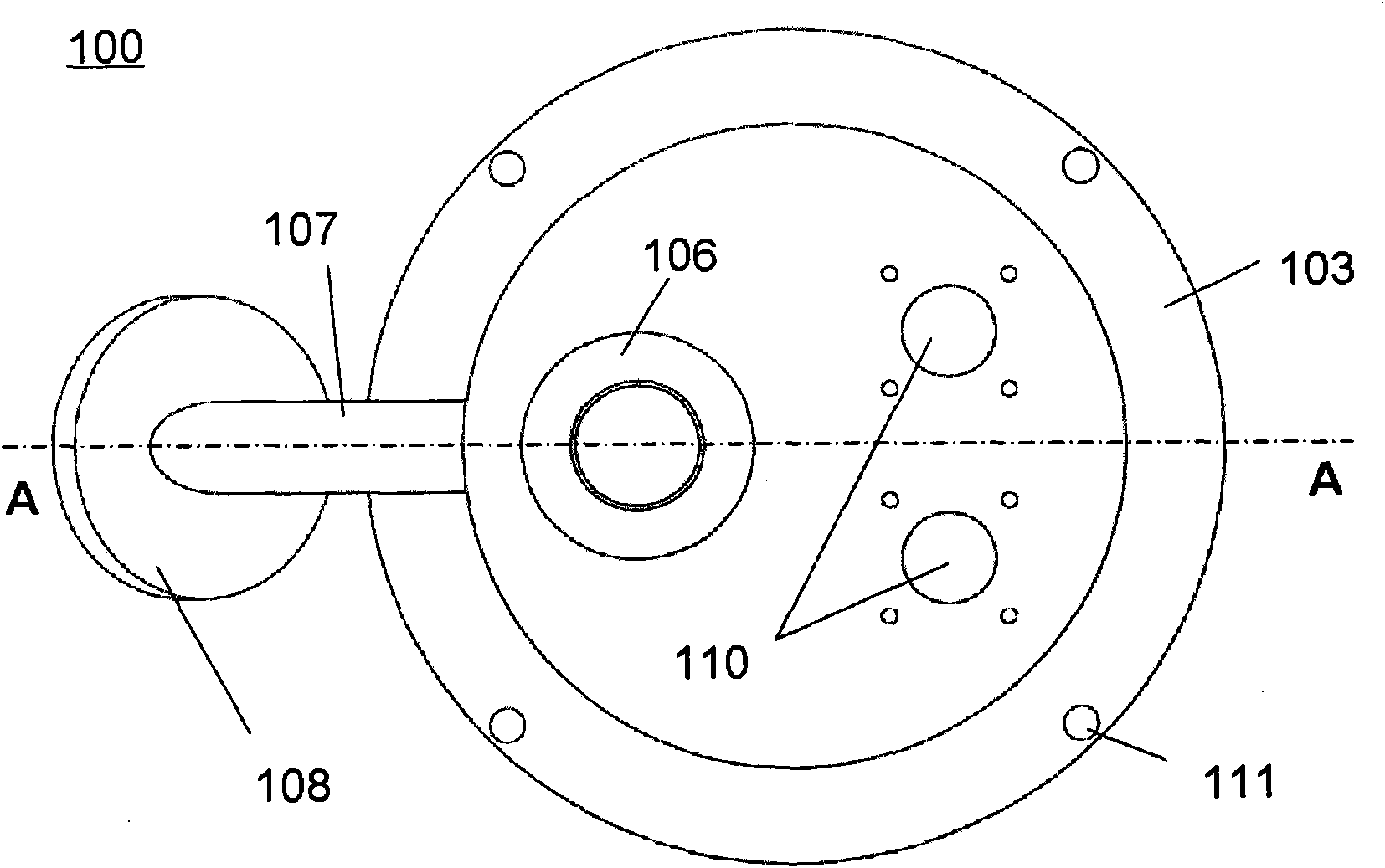

[0028] Wherein the structure of the vacuum cap 100 is as figure 2 As shown, it includes a vacuum cap top 101 and a vacuum cap side wall 102, wherein the vacuum cap top 101 is circular, which is combined on the cylindrical vacuum cap side wall 102, and the vacuum cap top 101 has a vacuum interface 106 and a socket hole 110. There is an outwardly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com