Roof membrane pressing machine of lithium thionyl chloride battery

A lithium sub-battery and top cover technology, applied in the field of machining devices, can solve problems such as low efficiency, hidden safety hazards, and low production efficiency, and achieve the effects of improving the working environment, saving production costs, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to facilitate the understanding of those skilled in the art, the structural principle of the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings:

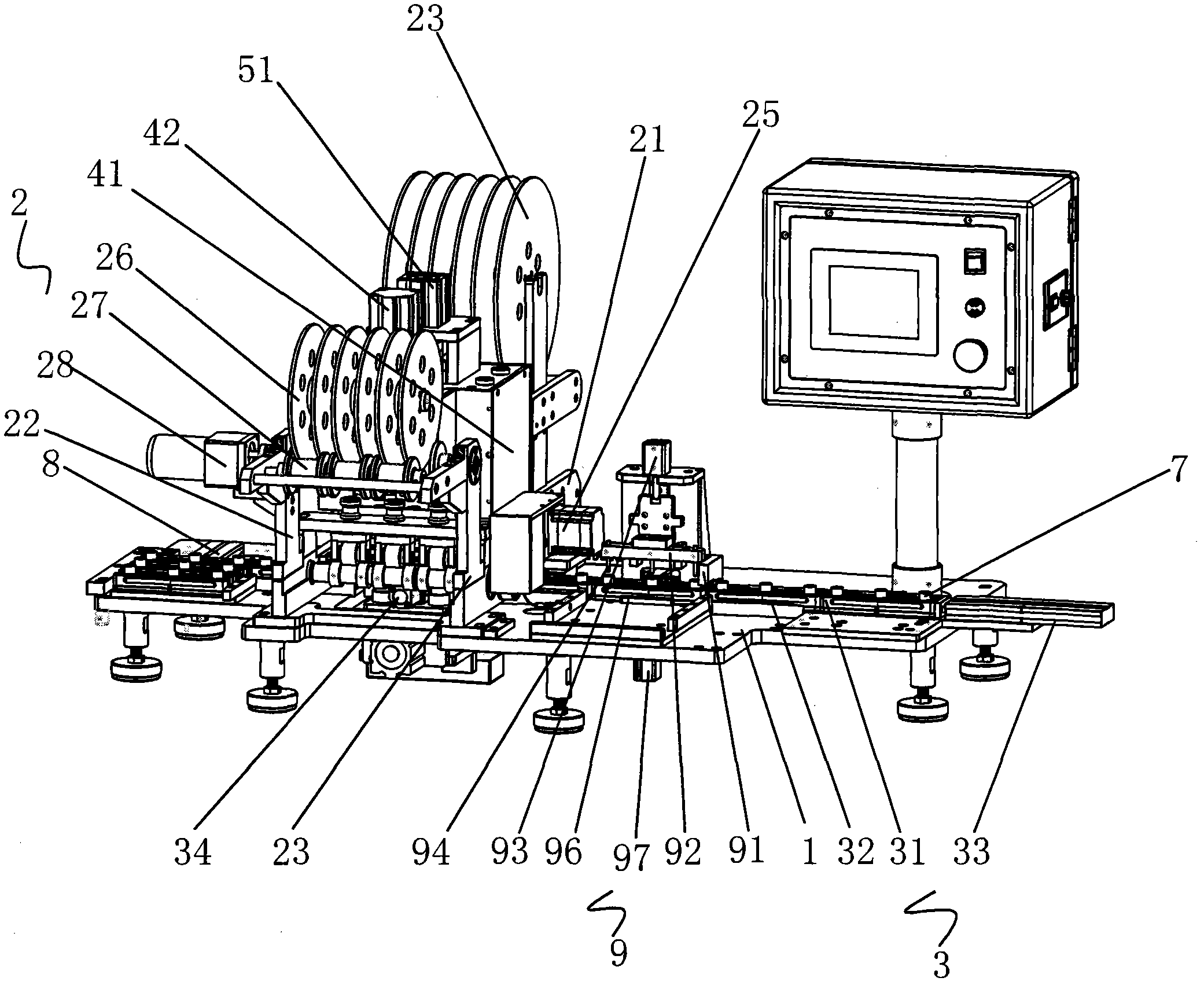

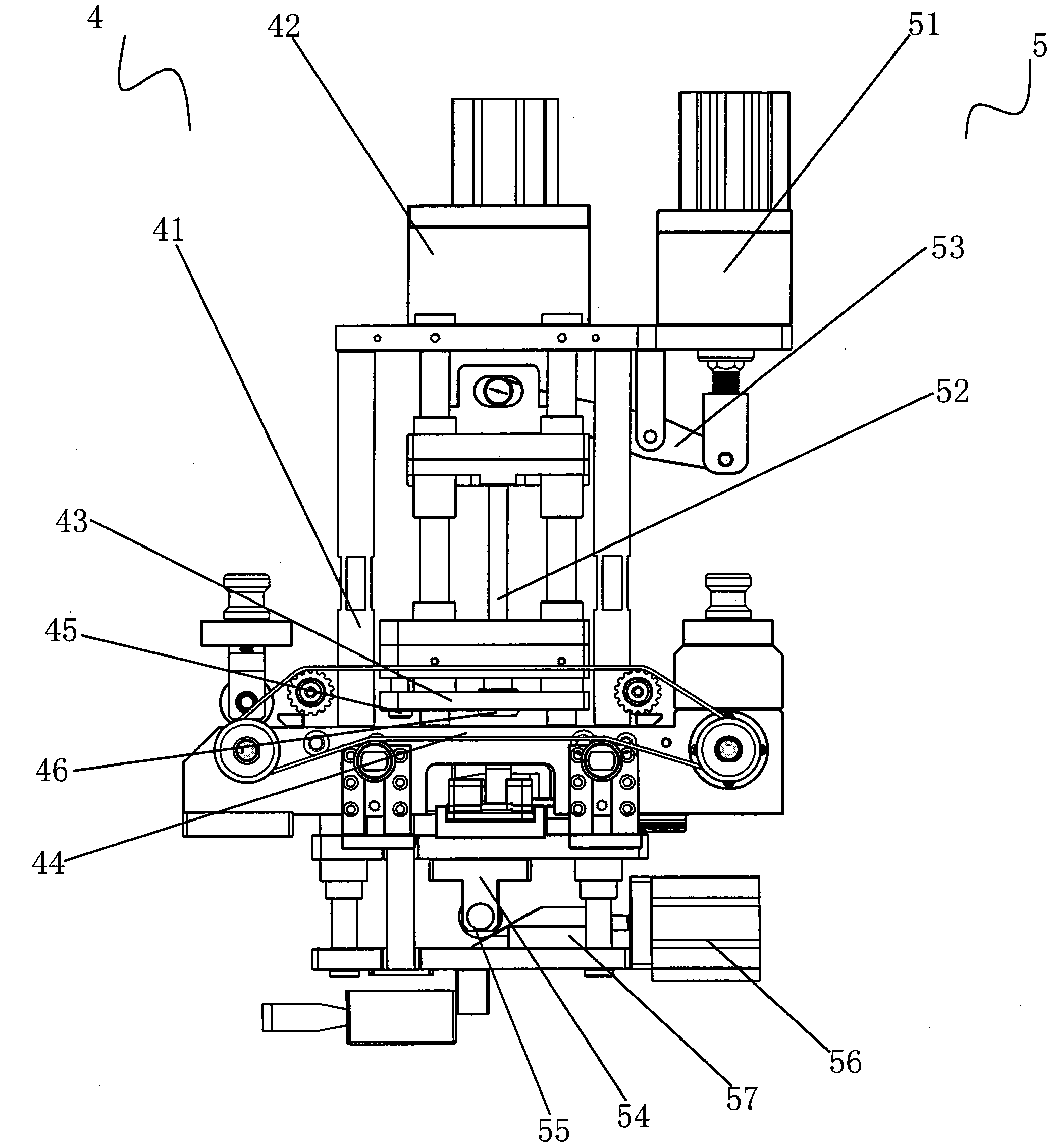

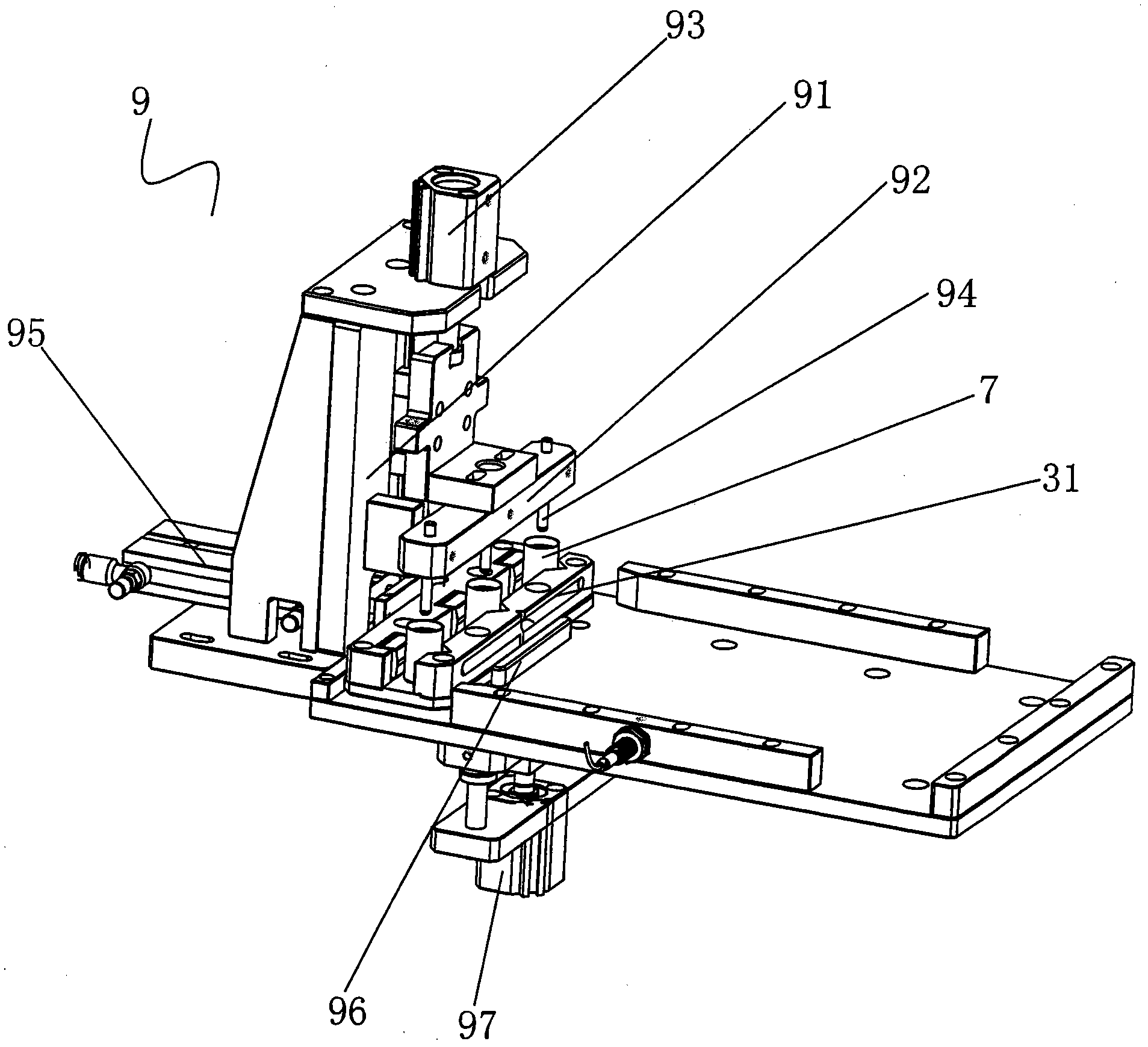

[0019] as attached Figure 1-3 As shown, a Li-sub-battery top cover film pressing machine includes a workbench 1 on which a top cover film feeding mechanism 2, a battery steel case component feeding mechanism 3, a detection mechanism 9 and a punching and cutting mechanism are sequentially arranged. Mechanism 4 and press-in mechanism 5, roof film feeding mechanism 2 transports the top cover film to the press-in station of press-in mechanism 5, battery steel case assembly feeding mechanism 3 transports battery steel case assembly 7 to press-in mechanism 5 Pressing into the station, the battery steel case assembly 7 is composed of a steel case, bottom film, edge film, PTFE, and carbon beads, and the bottom film, edge film, PTFE, and carbon beads...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com