Numerical control aspherical processing method adopting tangent method and machine tool

A processing method and aspheric surface technology, applied in metal processing equipment, grinding machines, manufacturing tools, etc., can solve the problems of difficult processing of aspheric optical parts, and achieve the effect of simple and easy operation technology, easy promotion and popularization, and reduced processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

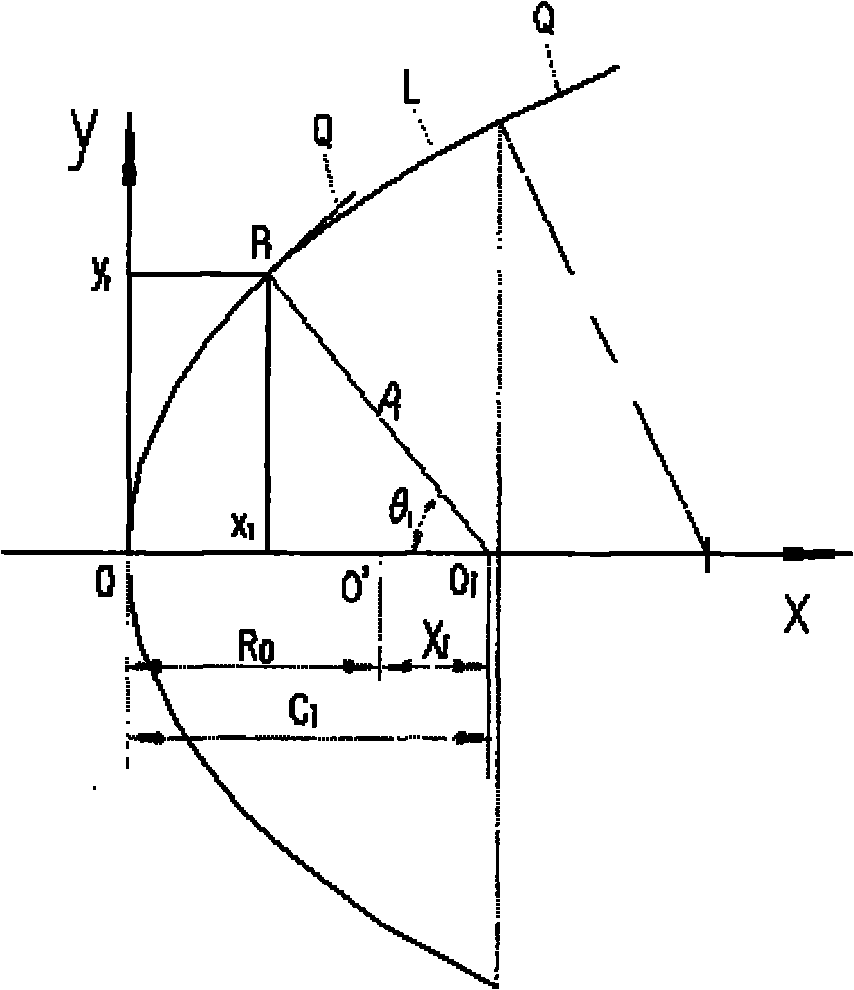

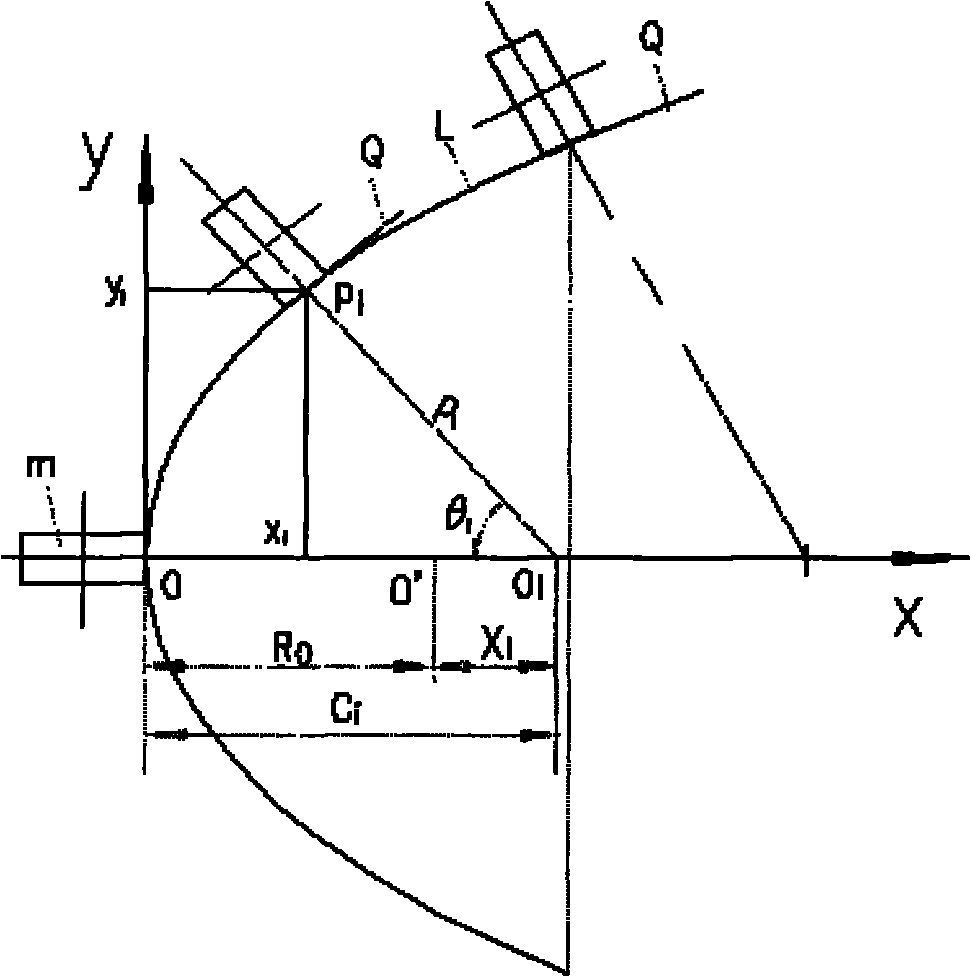

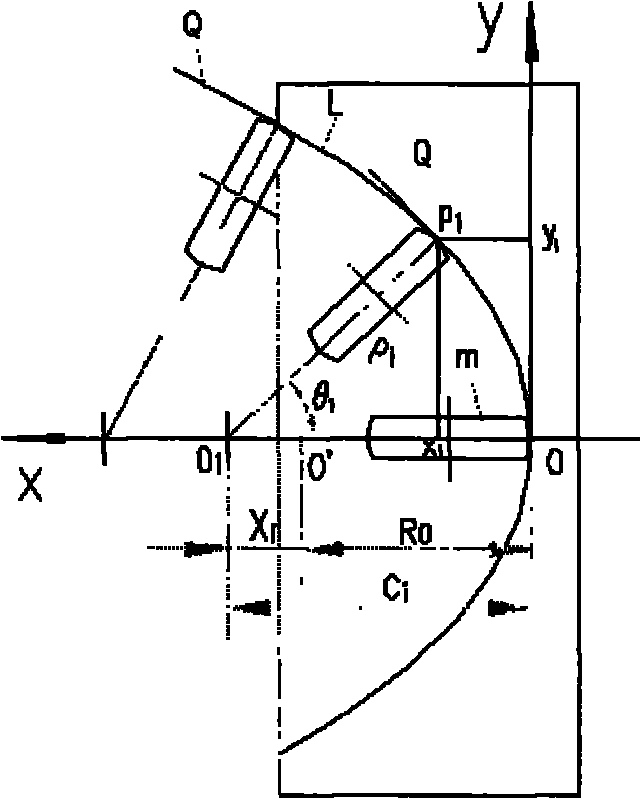

[0041] figure 1 The geometrical characteristics of any aspherical meridional profile locus curve L given in the optical design shown can be given by the mathematical equation X=f(y). That is, given any y i The value can be substituted into the given equation to find the corresponding x i value, so any point P of the given equation i (x i 、y i ) can be obtained. The curve of a circle has the characteristics of countless axes of symmetry, while the curve of an aspheric surface has only one axis of symmetry OX. Any point P other than the vertex O of the curve L i The normal ρ i Intersection O with the axis of symmetry OX i The distance is Ci (Ci=Ro+Xi), and the included angle is θ i , so at any point on the curve, you can also use P i (Ci, ρ i , θ i )To represent. According to the given curve equation, any P can be deduced by using the knowledge of elementary and advanced mathematics. i Point characteristic parameters Ci, ρ i and θ i The mathematical expression of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com