Nanometer reinforcing method of completely-regenerative concrete aggregate

A technology of recycled concrete and recycled aggregates, which is applied in the direction of sustainable waste treatment, solid waste management, and climate sustainability. Time, increase strength and durability, and strong permeability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

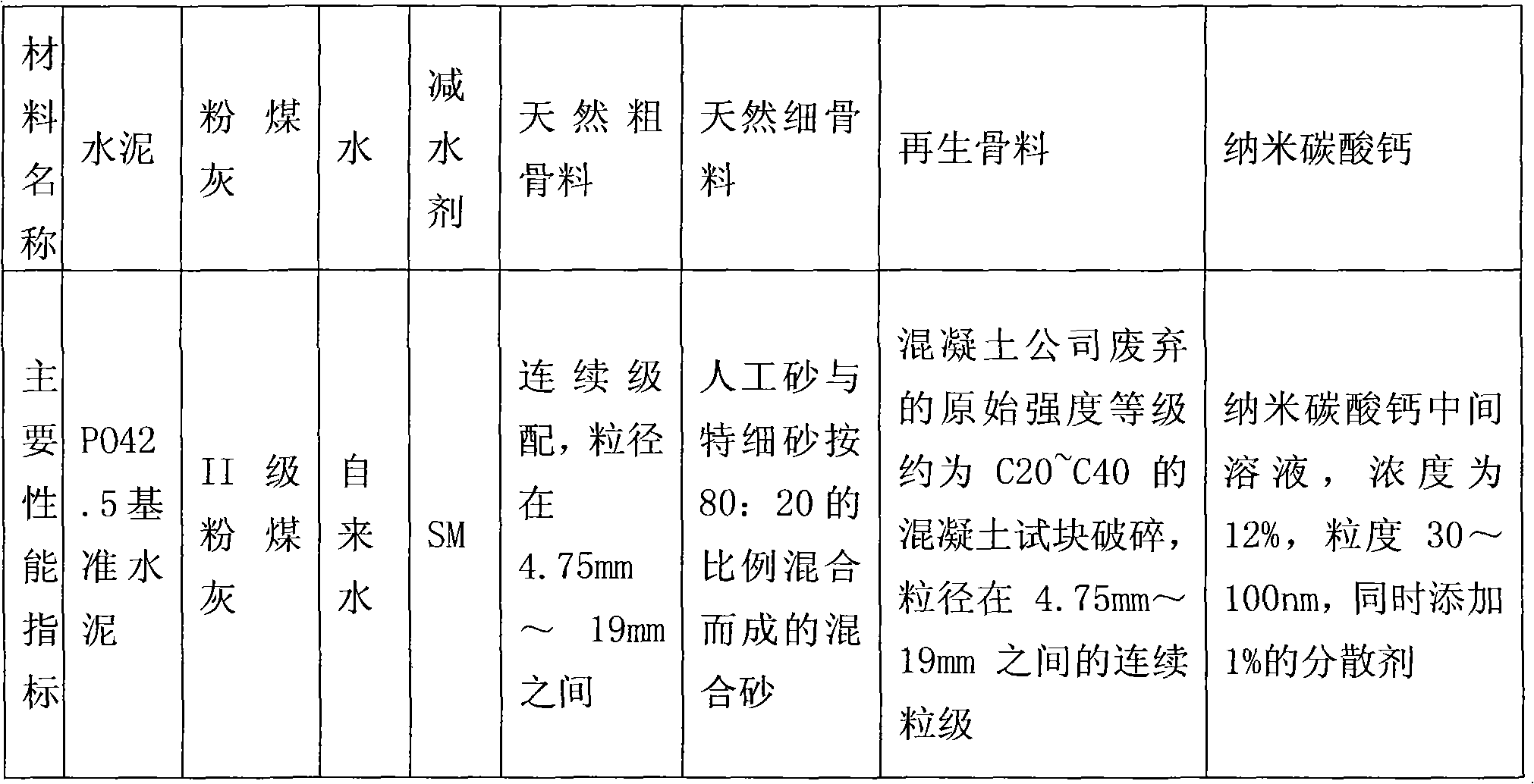

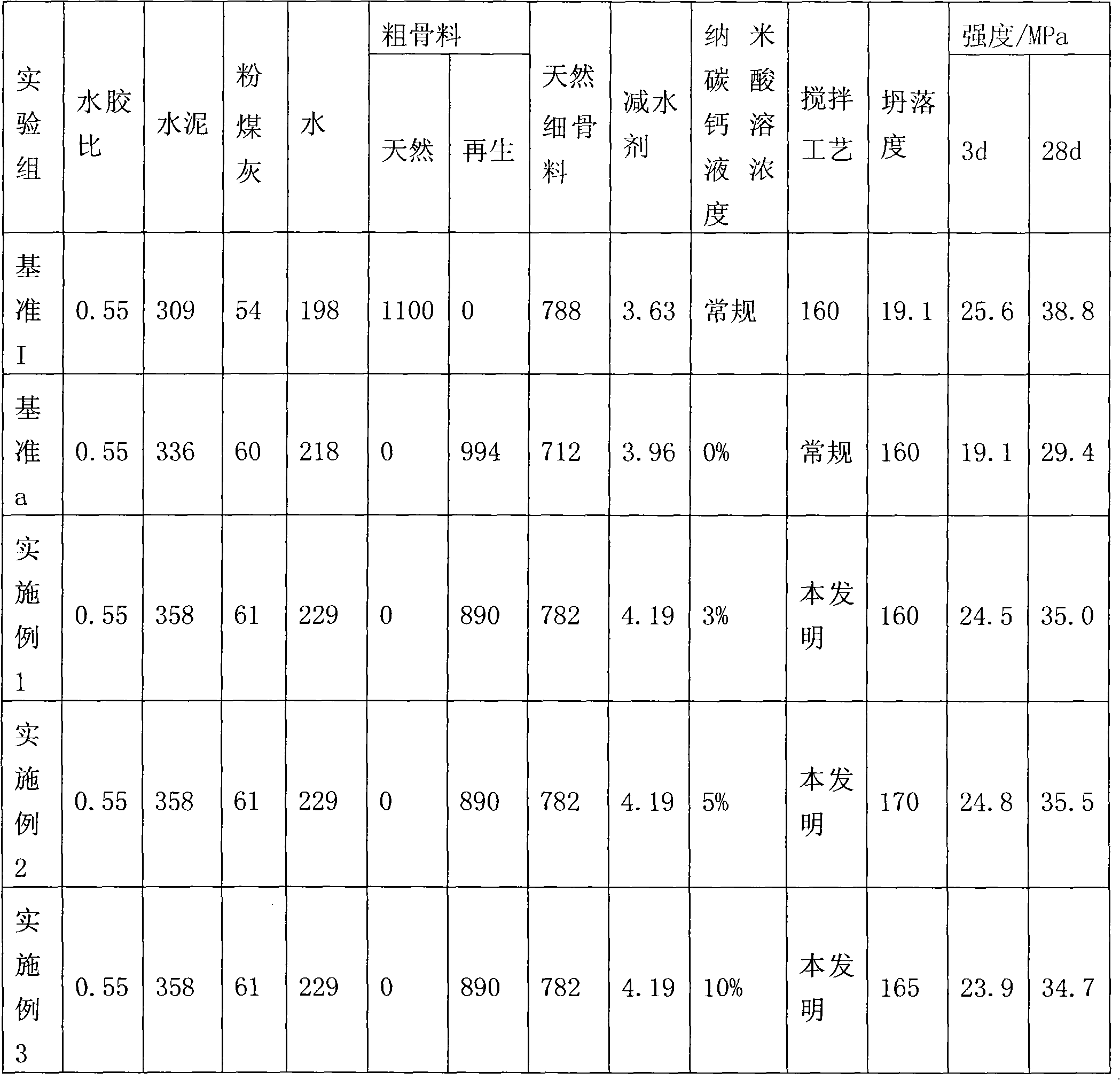

[0010] The materials used are listed in Table 1 below.

[0011] Table 1. Examples 1-3 experimental materials

[0012]

[0013] The concrete mix ratio of each embodiment is shown in Table 2. Before mixing concrete, first use nano-calcium carbonate solution, dispersant and water to prepare solutions with nano-calcium carbonate concentrations of 3%, 5%, 10%, and dispersant content of 1%, and then soak the recycled aggregate in the solution for 45 minutes. Afterwards, the recycled aggregate is taken out to make its surface wet (the moisture content of the aggregate at this time is determined to be 9.12%, 9.58%, and 9.72%), and it is stirred with part of the cementitious material for 20-30 seconds, and then sand and remaining glue are added. coagulant and high-efficiency water reducer, and then stirred for 20 to 30 seconds, then added water and stirred for 2 minutes to obtain the fully recycled concrete. Among them, the amount of fly ash is 15%, and the amount of water reducer...

Embodiment 4~6

[0017] The materials used are shown in Table 3 below.

[0018] Table 3. Embodiment 4~6 experimental material

[0019]

[0020]

[0021] The concrete mix ratio of each embodiment is shown in Table 4. Before mixing concrete, first use nano-calcium carbonate solution, dispersant and water to prepare a solution with a concentration of nano-calcium carbonate of 5% and a dispersant content of 1%, and then soak the recycled aggregate in the solution for 30min, 45min, and 60min respectively, and then Take out the recycled aggregate to make its surface wet (the moisture content of the aggregate is 8.62%, 9.58%, and 9.60% at this time, respectively), and stir with part of the cementitious material for 20-30 seconds, then add sand and the remaining gelatinized materials and high-efficiency water reducer, and then stirred for 20 to 30 seconds, then added water and stirred for 2 minutes to obtain the fully recycled concrete. Among them, the amount of mineral powder is 15%, and the ...

Embodiment 7~10

[0026] The materials used are shown in Table 5 below.

[0027] Table 5. Embodiment 7~10 experimental materials

[0028]

[0029] The concrete mix ratio of each embodiment is shown in Table 6. Before mixing concrete, first use nano-calcium carbonate solution, dispersant and water to prepare a solution with a concentration of nano-calcium carbonate of 5% and a dispersant content of 1%, and then soak the recycled aggregate in the solution for 45 minutes, and then the recycled aggregate Take it out to make its surface wet (the moisture content of the aggregates at this time is determined to be 9.58%), stir with part of the cementitious material for 20 to 30 seconds, then add sand, remaining cementitious material and high-efficiency water reducer, and stir for another 20 seconds. ~30s, then add water and stir for 2 minutes to obtain the fully recycled concrete. Among them, the dosage of water reducer is 1%. Under standard curing conditions, the relevant data such as its mecha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com