Precursor composition of polyimide and method for preparing polyimide

A polyimide and composition technology, applied in the field of polyimide precursor composition, can solve problems such as side chain damage, time-consuming manufacturing process, and safety issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

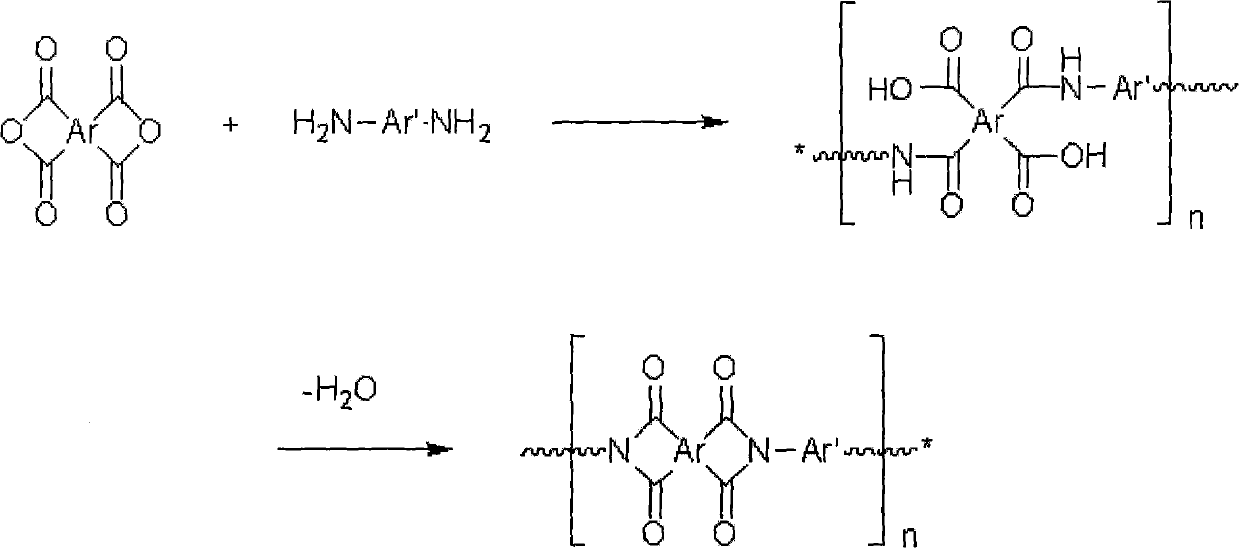

Method used

Image

Examples

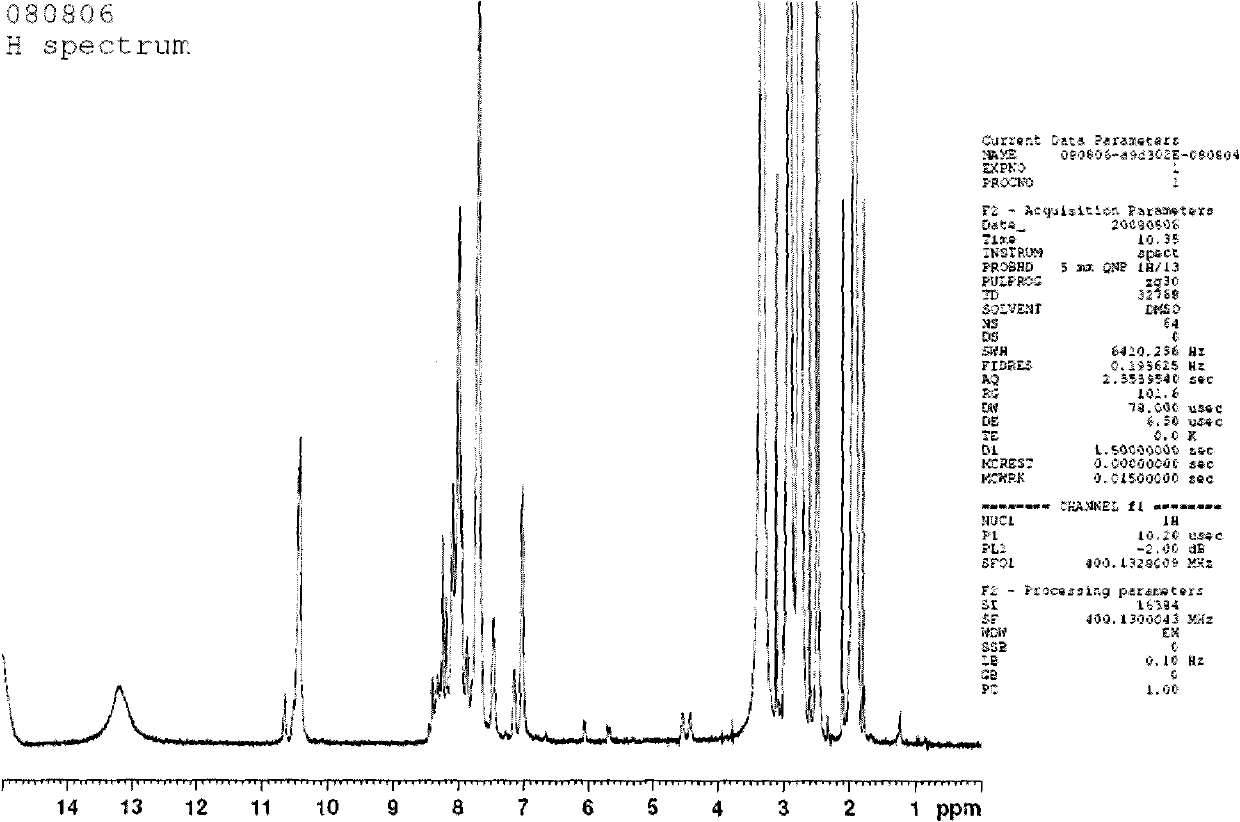

Embodiment 1

[0122] 2.181 grams (0.01 moles) of pyromellitic dianhydride (pyromellitic dianhydride, hereinafter referred to as PMDA) were dissolved in 200 grams of N-methyl-2-pyrrolidinone (N-methyl-2-pyrrolidinone; hereinafter referred to as NMP), The resulting mixture was heated to 50°C and the reaction was stirred for two hours. 2.322 g (0.02 mol) of 2-hydroxyethyl acrylate (2-Hydroxyethyl acrylate, hereinafter referred to as HEA) was added dropwise, and reacted and stirred at a constant temperature of 50° C. for two hours. Thereafter, 20.024 grams (0.1 mole) of 4,4'-oxidized dianiline (4,4'-oxy-dianiline, hereinafter referred to as ODA) was added to the solution, and after it was completely dissolved, 18.0216 grams (0.09 mol) of PMDA, reacted and stirred for six hours at a constant temperature of 50°C. Then 3.243 g (0.02 mol) of N, N'-carbonyldiimidazole (N, N'-Carbonyldiimidazole; CDI) was added, and the reaction was stirred at a constant temperature of 50° C. for one hour.

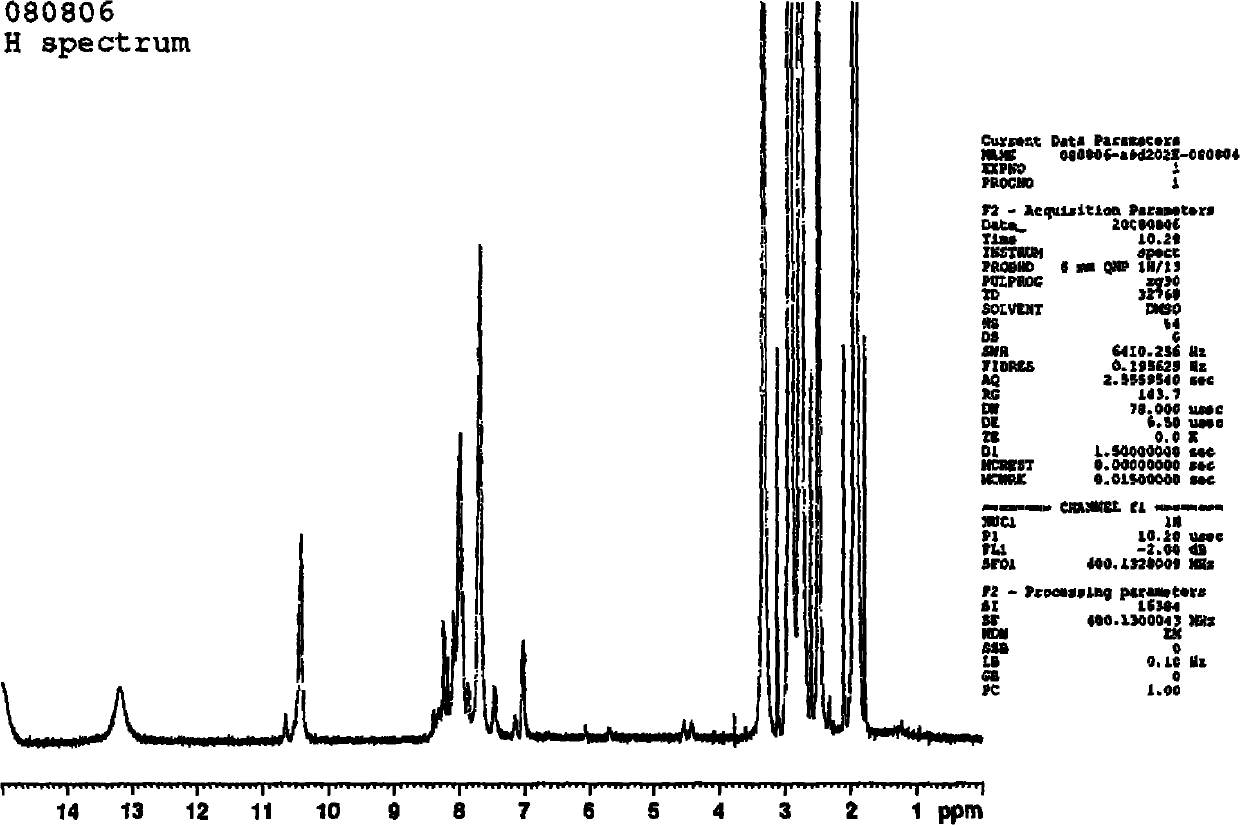

Embodiment 2

[0126] 2.181 grams (0.01 mol) of PMDA were dissolved in 200 grams of NMP, heated to 50°C and the reaction was stirred for two hours. 2.60 g (0.02 mol) of 2-hydroxyethyl methacrylate (2-hydroxyethyl methacrylate; hereinafter referred to as HEMA) was slowly added dropwise, and the reaction was stirred at a constant temperature of 50° C. for two hours. Add 20.024 g (0.1 mole) of ODA to the solution, and after it is completely dissolved, add 18.0216 g (0.09 mole) of PMDA, react and stir for six hours at a constant temperature of 50°C. Then add 3.243g (0.02mol) of CDI, react and stir at a fixed temperature of 50°C for one hour.

Embodiment 3

[0128] 2.181 grams (0.01 mol) of PMDA were dissolved in 200 grams of NMP, heated to 50°C and the reaction was stirred for two hours. 2.322 g (0.02 mol) of HEA was slowly added dropwise, and the reaction was stirred at a constant temperature of 50° C. for two hours. Add 10.814 grams (0.1 moles) of p-phenylenediamine (para-phenylenediamine, hereinafter referred to as pPDA) to the solution, and after it is completely dissolved, add 18.0216 grams (0.09 moles) of PMDA, and react with stirring at a constant temperature of 50°C six hours. Then add 3.243g (0.02mol) of CDI, react and stir at a fixed temperature of 50°C for one hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com