Novel high-speed electrical desalting and dewatering apparatus

An electric desalination and dehydration, high-speed technology, applied in the direction of electricity/magnetic dehydration/demulsification, etc., can solve the problems of reducing, unable to meet the energy saving and emission reduction, and increasing the power consumption of electric desalination equipment, and achieve the effect of improving the processing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

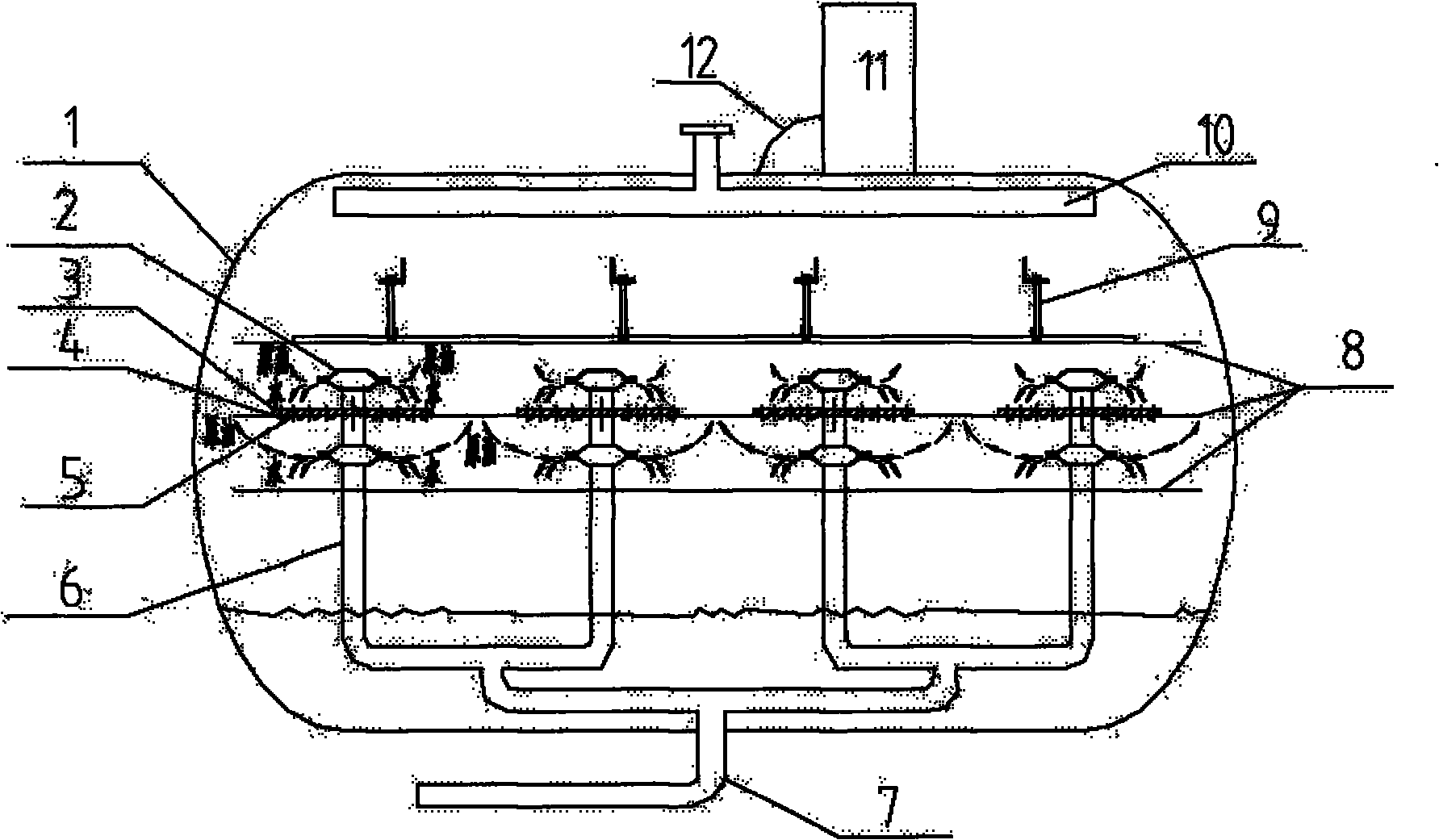

[0018] See attached figure 1 , a layout diagram of parts inside a tank of a new type of high-speed electric desalination and dehydration equipment in this embodiment.

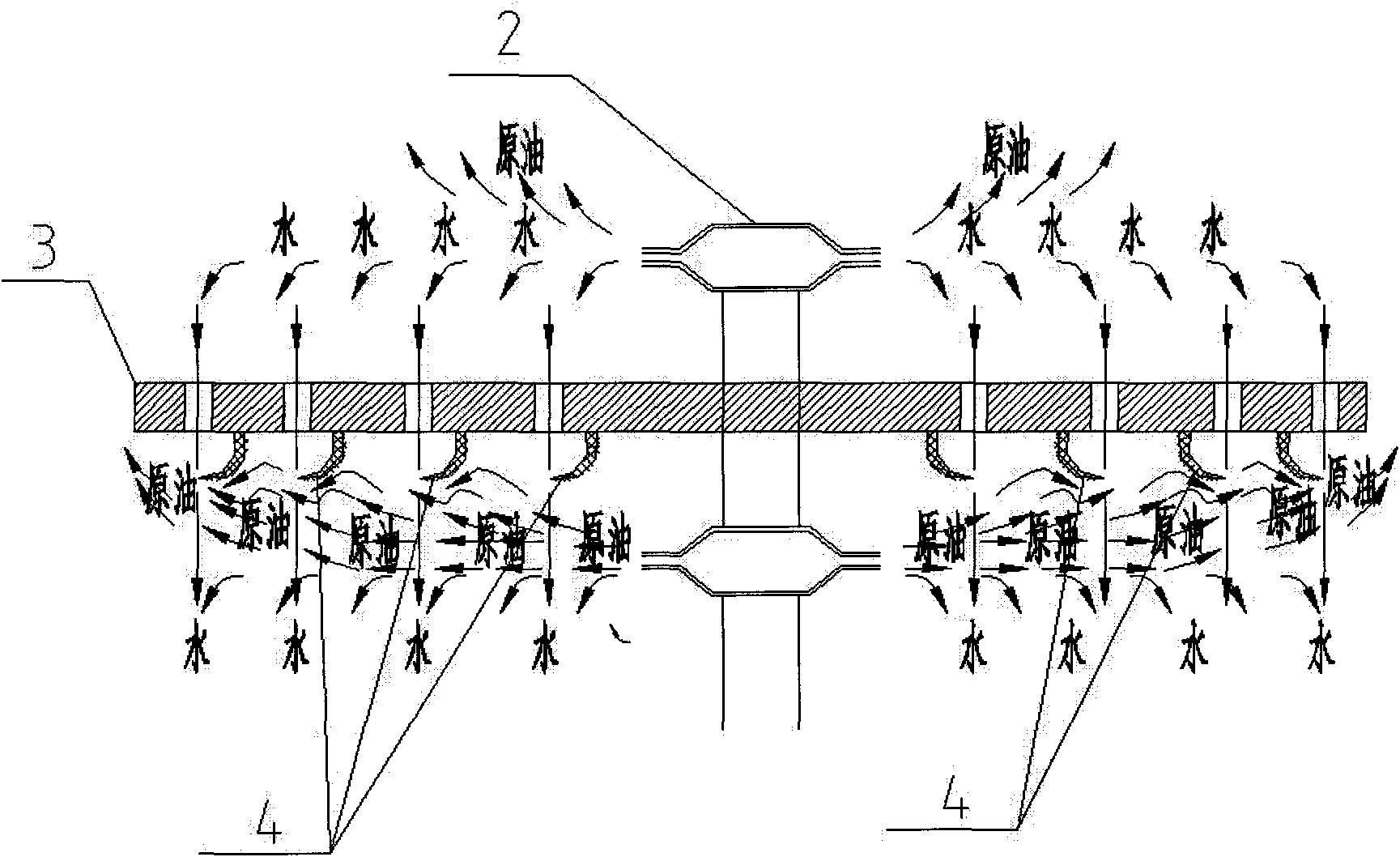

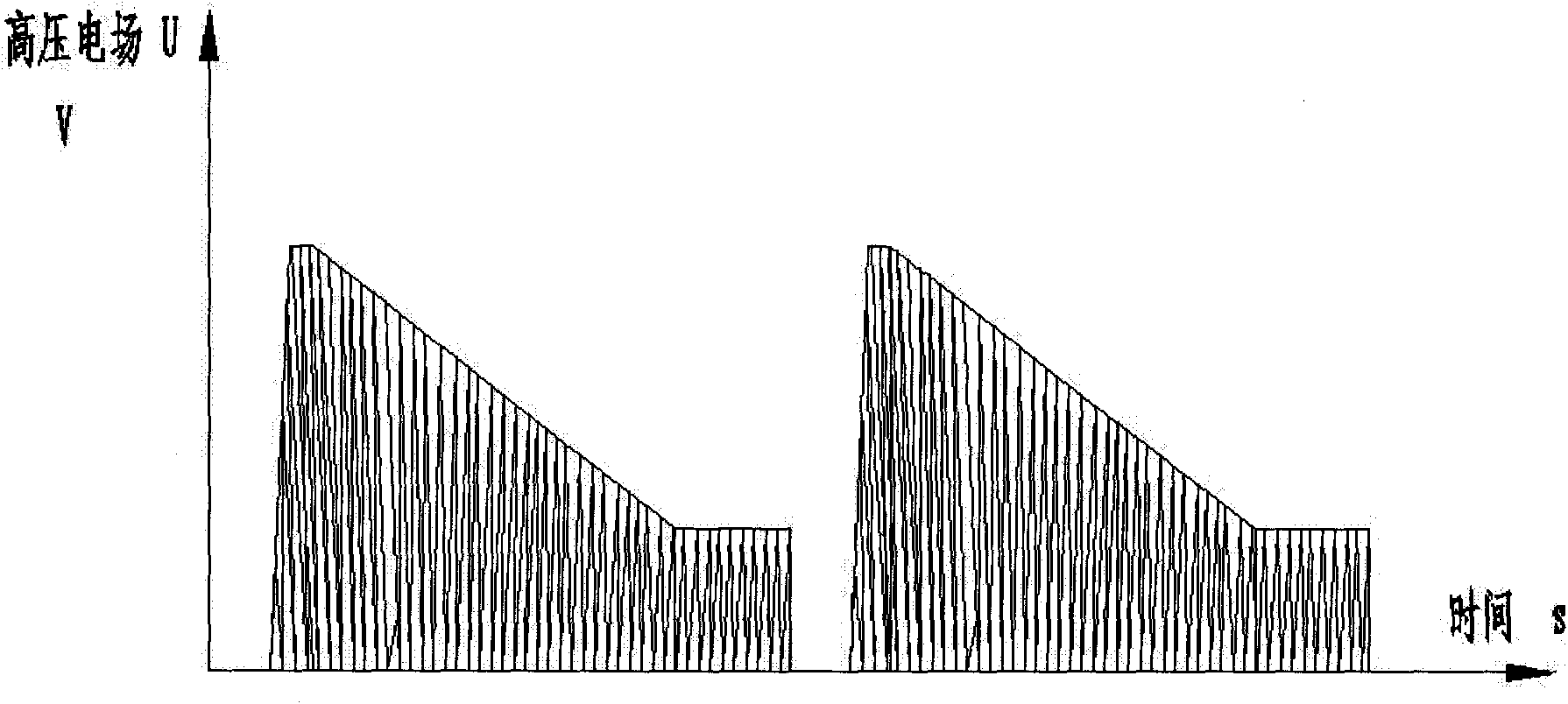

[0019] The crude oil emulsion composed of crude oil, water and demulsifier enters the oil inlet branch pipe (6) in the electric desalination and dehydration tank through the oil inlet main pipe 7 outside the electric desalination and electric dehydration tank (1), and then passes through the inlet pipe (6) designed in the middle of the tank body. The oil injector (2) sprays out, and under the action of a high-voltage electric field, oil-water separation, dehydration and desalination are carried out, and the separated crude oil is collected into the oil discharge collection pipe (10) at the top of the tank, and leaves the tank to complete the desalination process. The separated water settles at the bottom of the tank. When the electric desalination equipment is operating normally, the lower part of the electric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com