Rolling rotor refrigeration compressor with function of preventing liquid impact

A technology of refrigeration compressors and rolling rotors, applied in liquid fuel engines, machines/engines, rotary piston machines, etc., can solve the problems of waste of resources, heat load reduction, poor compressibility, etc., achieve convenient processing and assembly, prevent liquid prevent accidents and ensure reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

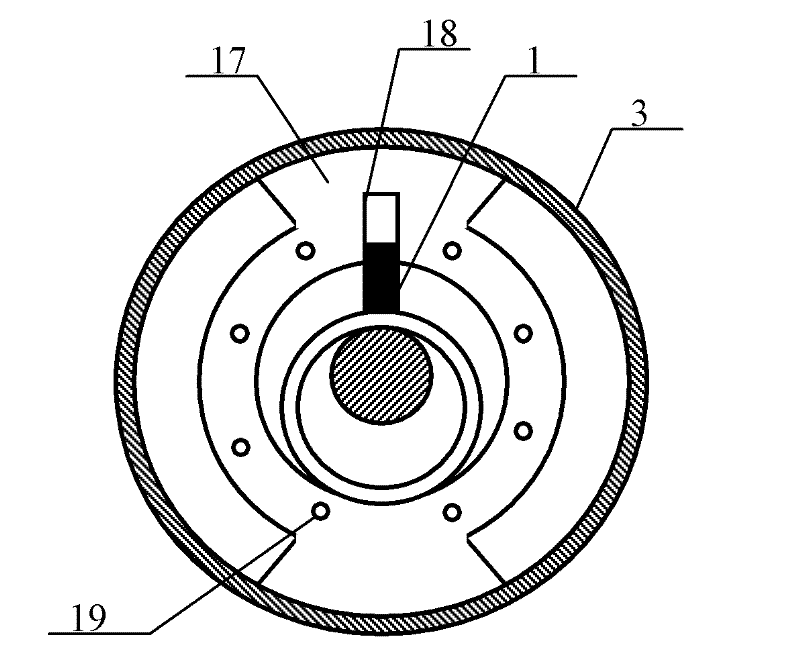

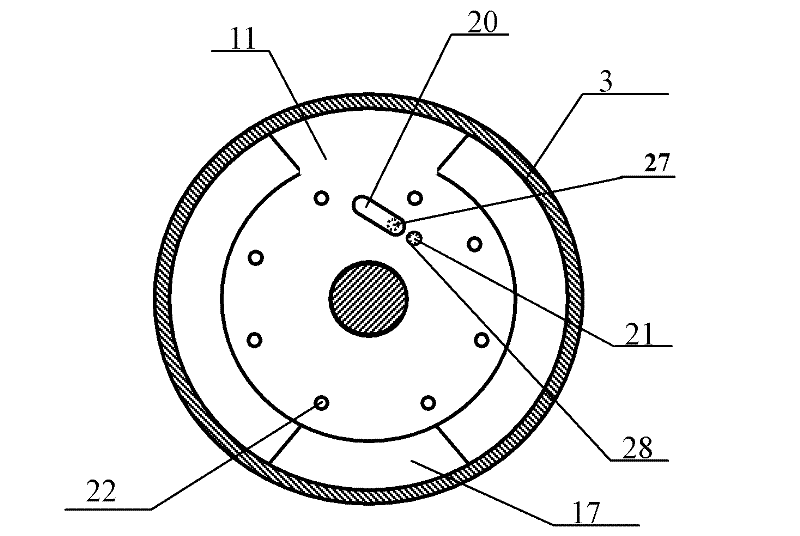

[0015] The schematic diagram of the rolling rotor refrigeration compressor with anti-liquid shock function of the present invention is as follows Figure 1 to Figure 5 As shown, it includes sliding plate 1, suction pipe 2, casing 3, motor stator 4, motor rotor 5, eccentric main shaft 6, right end cover 8, sleeve 9, eccentric oil passage 10, cover plate 11, oil suction pipe 13, Oil tank 14, left end cover 15, exhaust cavity 16, cylinder 17, exhaust pipe 29. The cylinder 17 is fixedly connected with the casing 3, the eccentric main shaft 6 is provided with an eccentric oil passage 10, and the right end cover 8 is set on the outside of the eccentric main shaft 6 and is fixed to the cylinder 17 by the sealing gasket and the screw 7 installed in the screw hole 19 connect. The cover plate 11 is sleeved on the outside of the eccentric main shaft 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com