Automatic helical feeding combustion boiler

An automatic feeding and boiler technology, applied in the field of boilers, can solve the problems of black smoke from the chimney, insufficient combustion of the coal seam, high slag temperature, etc., and achieve the effect of saving maintenance costs, considerable economic benefits, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

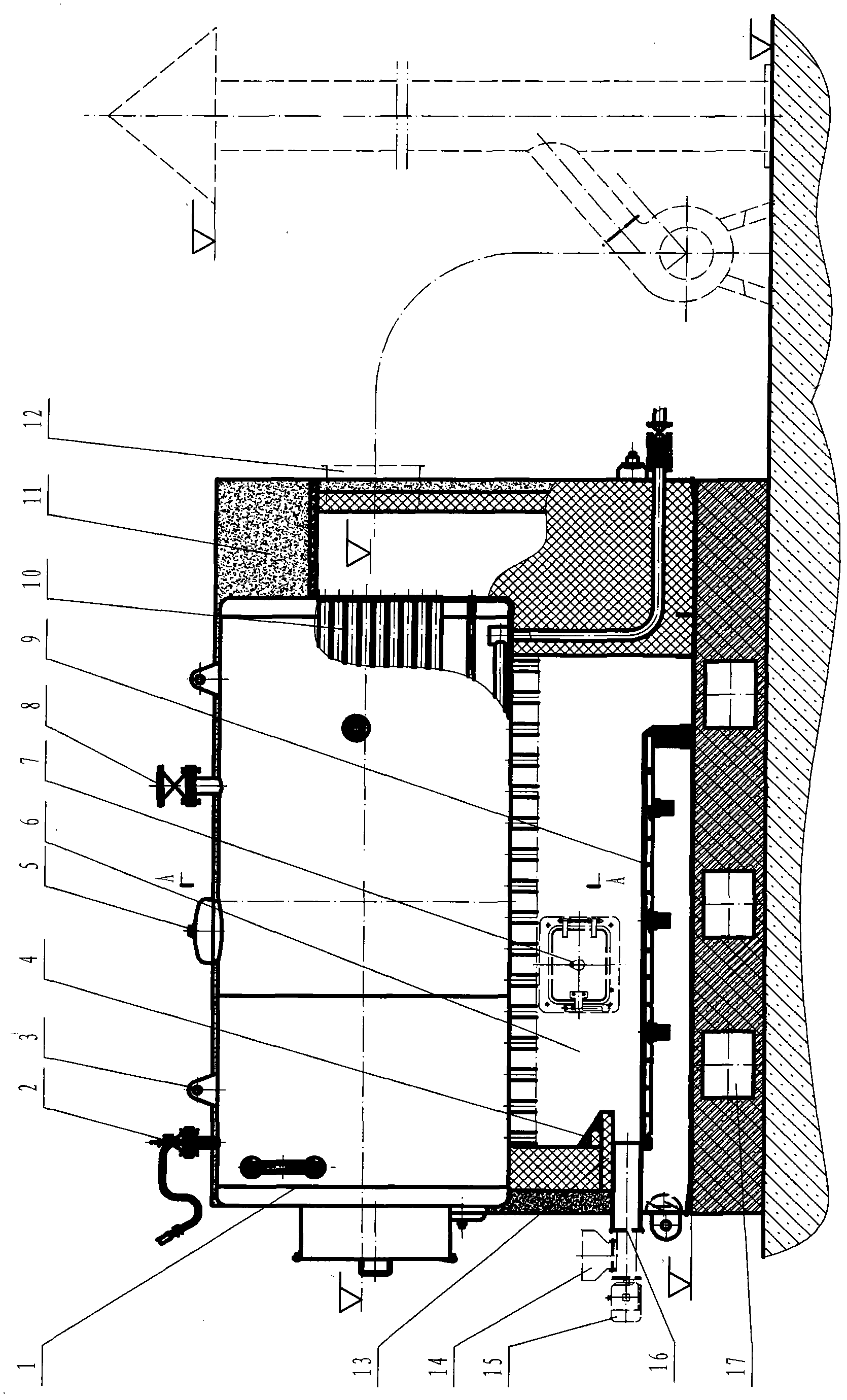

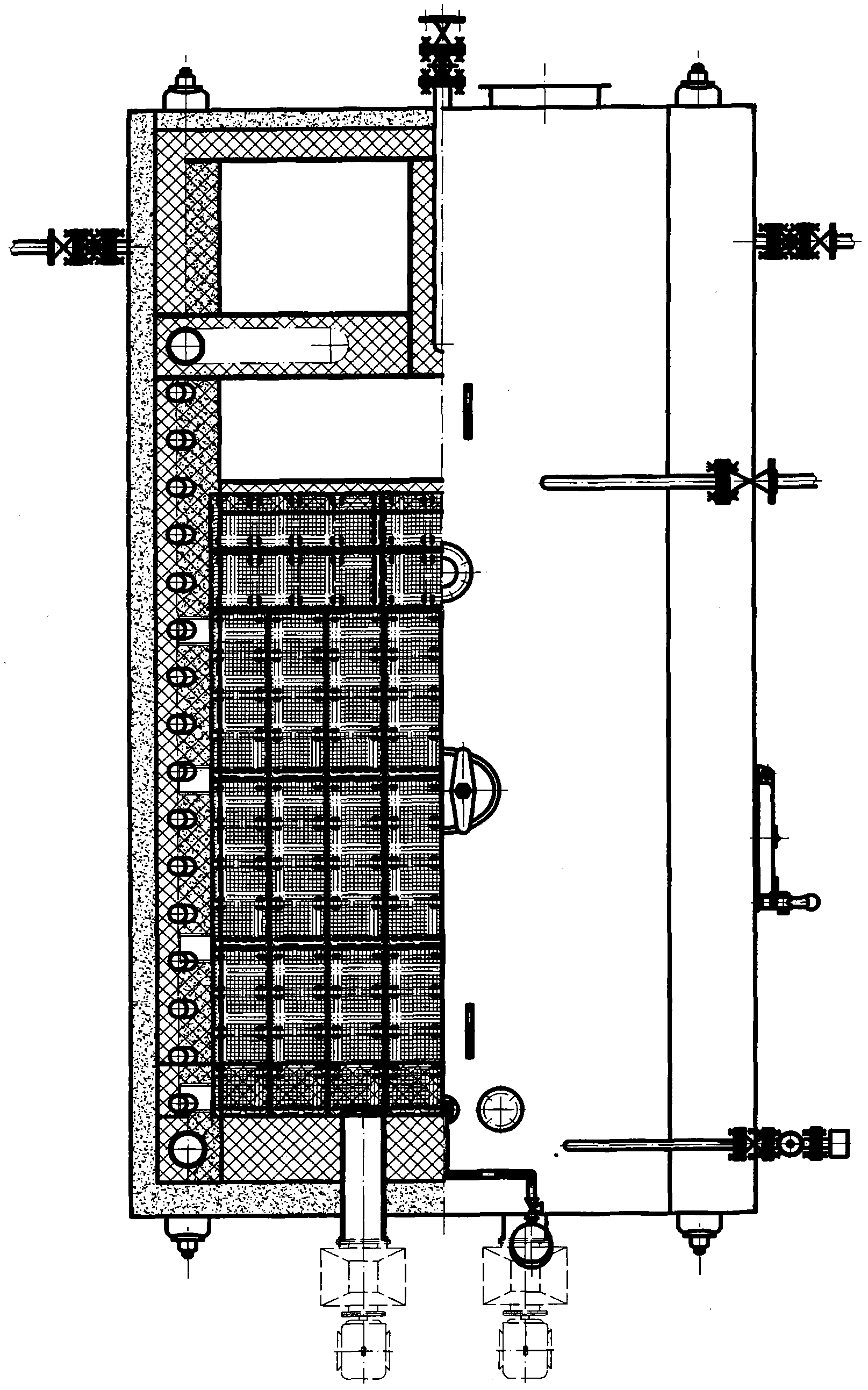

[0026] Embodiment 1, with reference to attached Figure 1 to Figure 10 , the fuel for the boiler (usually small granular briquettes and biomass particles) is sent into the furnace through the screw rod in front of the furnace, and the motor on the grate is controlled by frequency conversion, which can control the speed and amount of feed in time. We pass Adjust the air supply at the bottom of the grate so that the fuel can be fully ignited and burned in the furnace. Sensible heat and intermediate products such as H2, CH4, CnHm, Co and other combustible components are produced during this process; the air is blown through the bottom of the grate and directly enters the high-temperature combustion chamber for complete combustion and releases heat.

[0027] The combustion principle is divided into the following stages:

[0028] 1. Dehydration: The moisture in the fuel evaporates and gasifies when heated, and escapes from the fuel.

[0029] 2. Precipitation and combustion of vol...

Embodiment 2

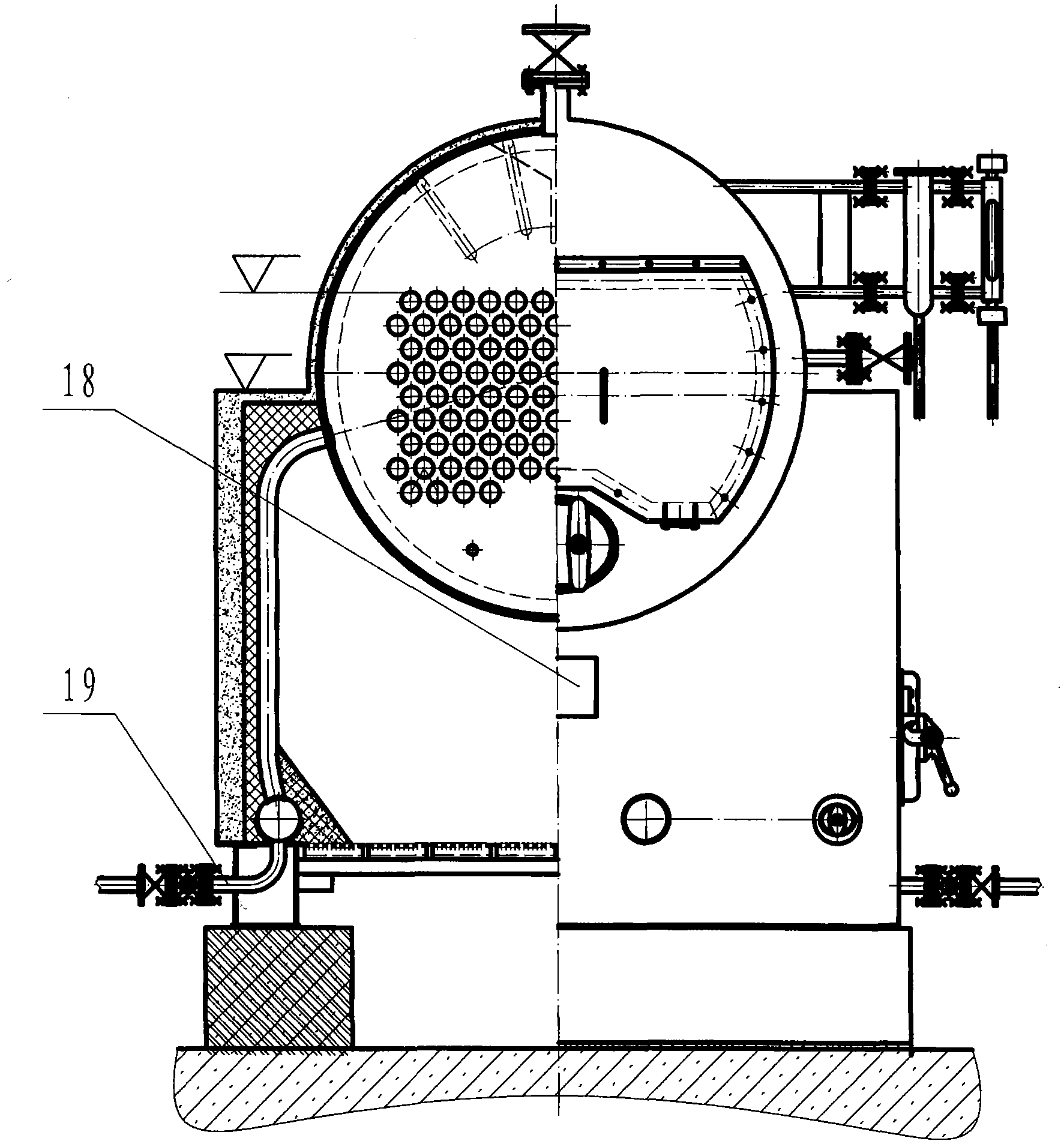

[0034] Embodiment 2, with reference to attached Figure 1 to Figure 10, when the spiral automatic feeding boiler of the present invention is applied to a vertical boiler, the discharge port of the screw propeller (16) is directly facing the boiler inlet, and the combustion chamber (6) of the boiler does not need to extend the plate (13), and the corners do not Build inclined plane (4), screw propeller (16) outer end connects electric motor (15), and the top surface of screw propeller (16) is feeding device (14), and the structure at this moment is that grate (9) face is Fuel, above the fuel is a combustion chamber (6), above the combustion chamber (6) are a furnace and a fire pipe, the fire pipe is connected to the water tank, and the water pipe is connected to a steam outlet and a hot water outlet. Coal, firewood, orange stalks are used to make granules for combustion. The fuel burns in the combustion chamber (6) almost in a static state, and the remaining small amount of as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com