Flat-pipe heat exchanger structure and assembling table thereof

A technology of heat exchangers and assembly tables, which is applied in the direction of tubular components, refrigeration components, heat exchange equipment, etc., can solve the problems of increased product cost, small contact area, and increased cold resistance, so as to reduce the use of welding processes and increase Contact area, effect of enhancing heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The structure of the heat exchanger of the present invention will be further described below with reference to the accompanying drawings.

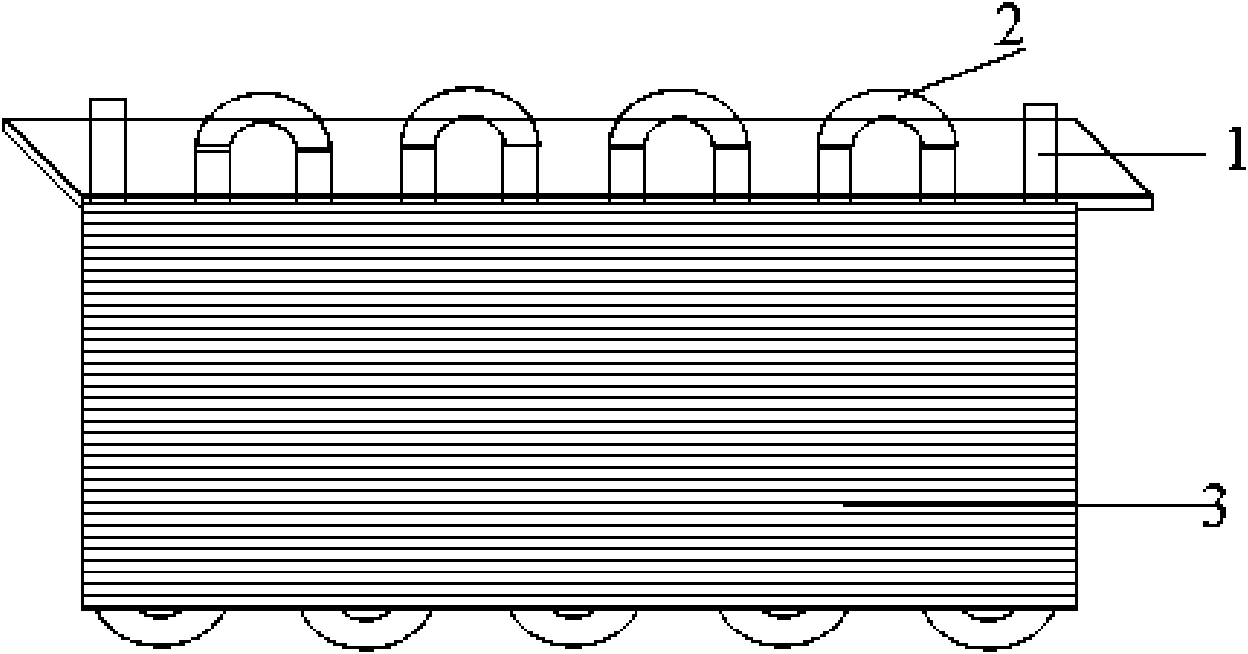

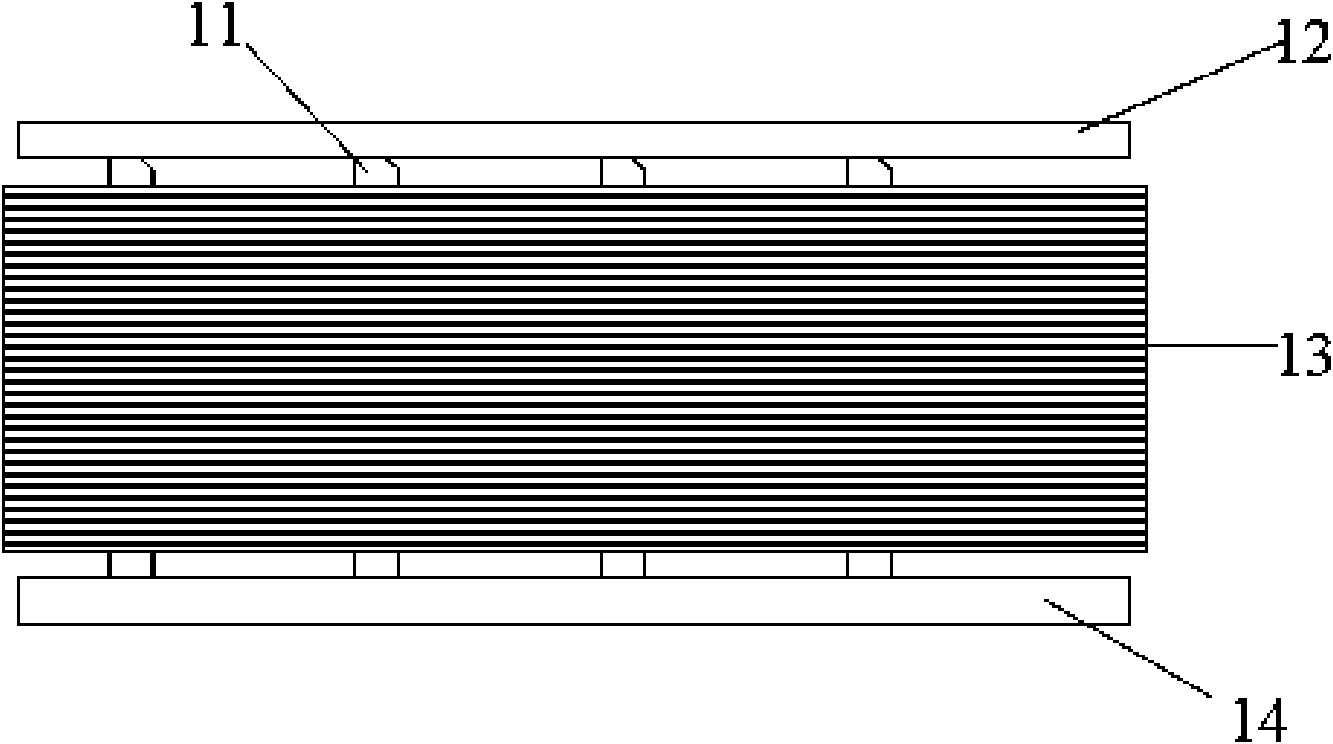

[0028] As shown in Figure 24, the heat exchanger structure of the present invention includes an inlet header 12, an outlet header 14, fins 13 that are tightly stacked between the inlet header 12 and the outlet header 14, and through the fins 13 will A flat pipe 11 in which the inlet header 12 and the outlet header 14 communicate.

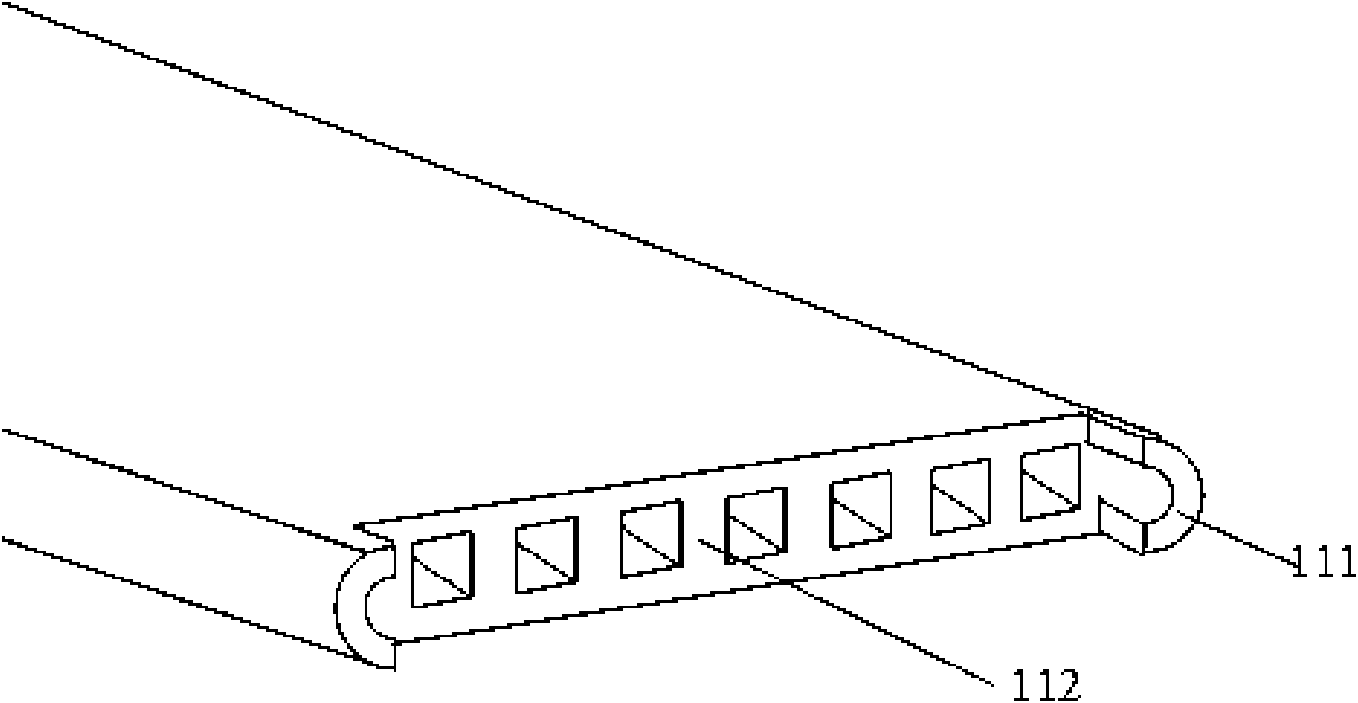

[0029] like image 3 As shown, the flat tube 11 of the present invention is a microchannel flat tube, generally an aluminum flat tube, and a plurality of partition plates 112 are arranged in its lumen, and the partition plates 112 extend along the pipeline direction of the flat tube 11 and The lumen is evenly divided into several microchannels. The cross-section of the flat tube 11 is a rounded rectangle, and the two arc-shaped side plates protrude forward in the direction of the pipe, that is, the two ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com