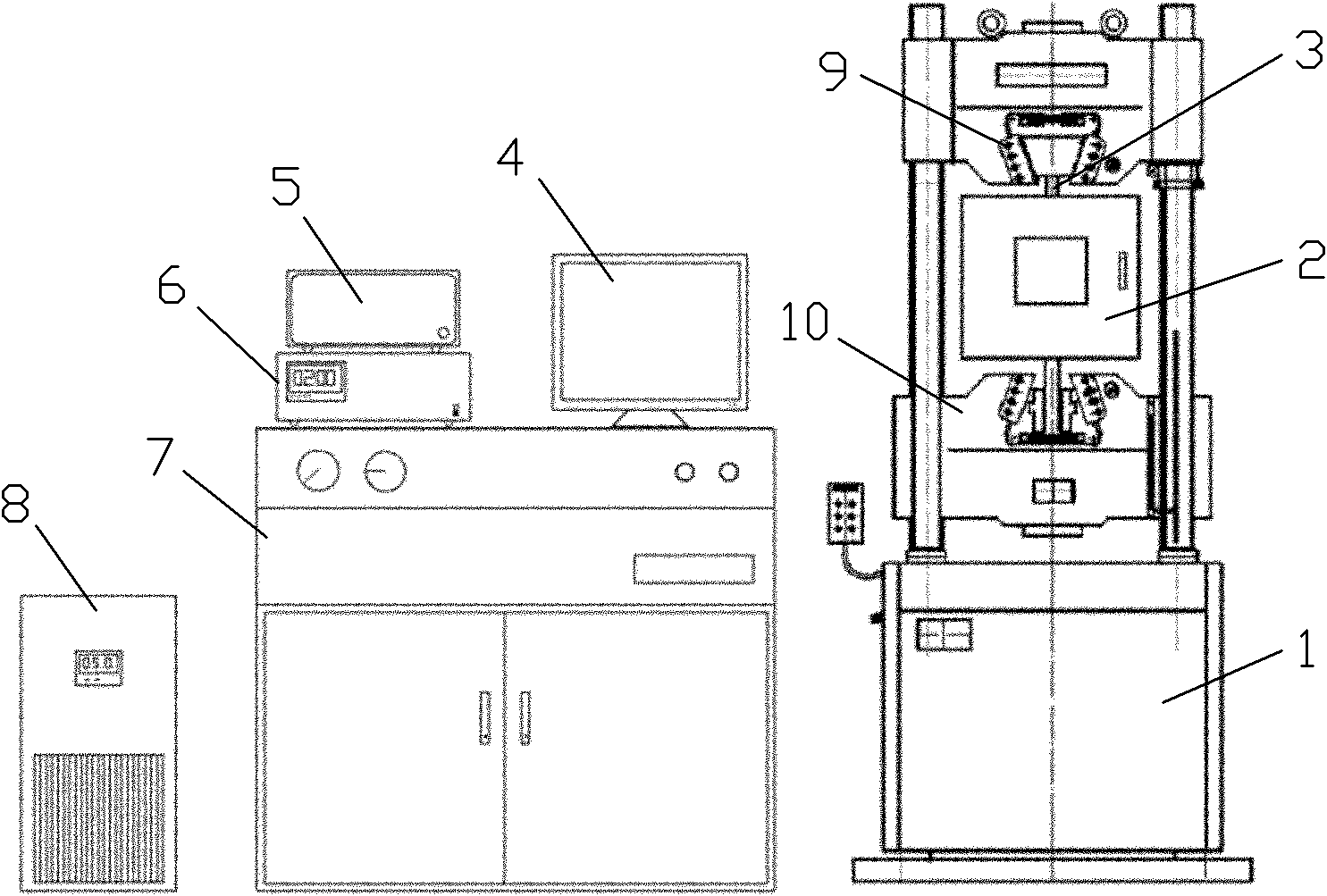

Device for testing high-temperature load-carrying properties of aluminum and aluminum alloy electric power apparatuses of power transmission line

A technology for transmission lines and power equipment, applied to measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve the problem of inability to maintain high loads, failure to truly reflect the damage strength of power equipment, and short load retention time And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

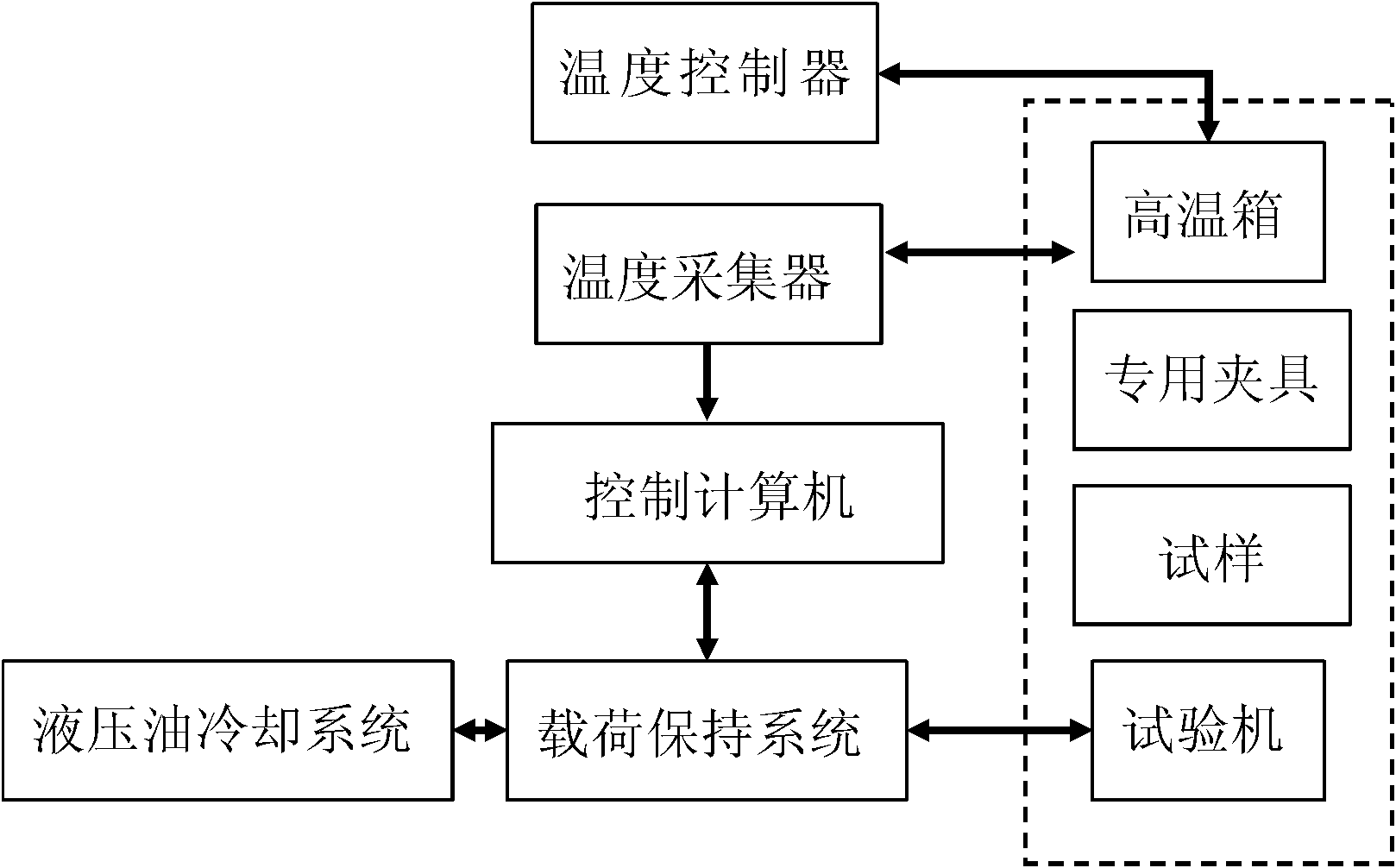

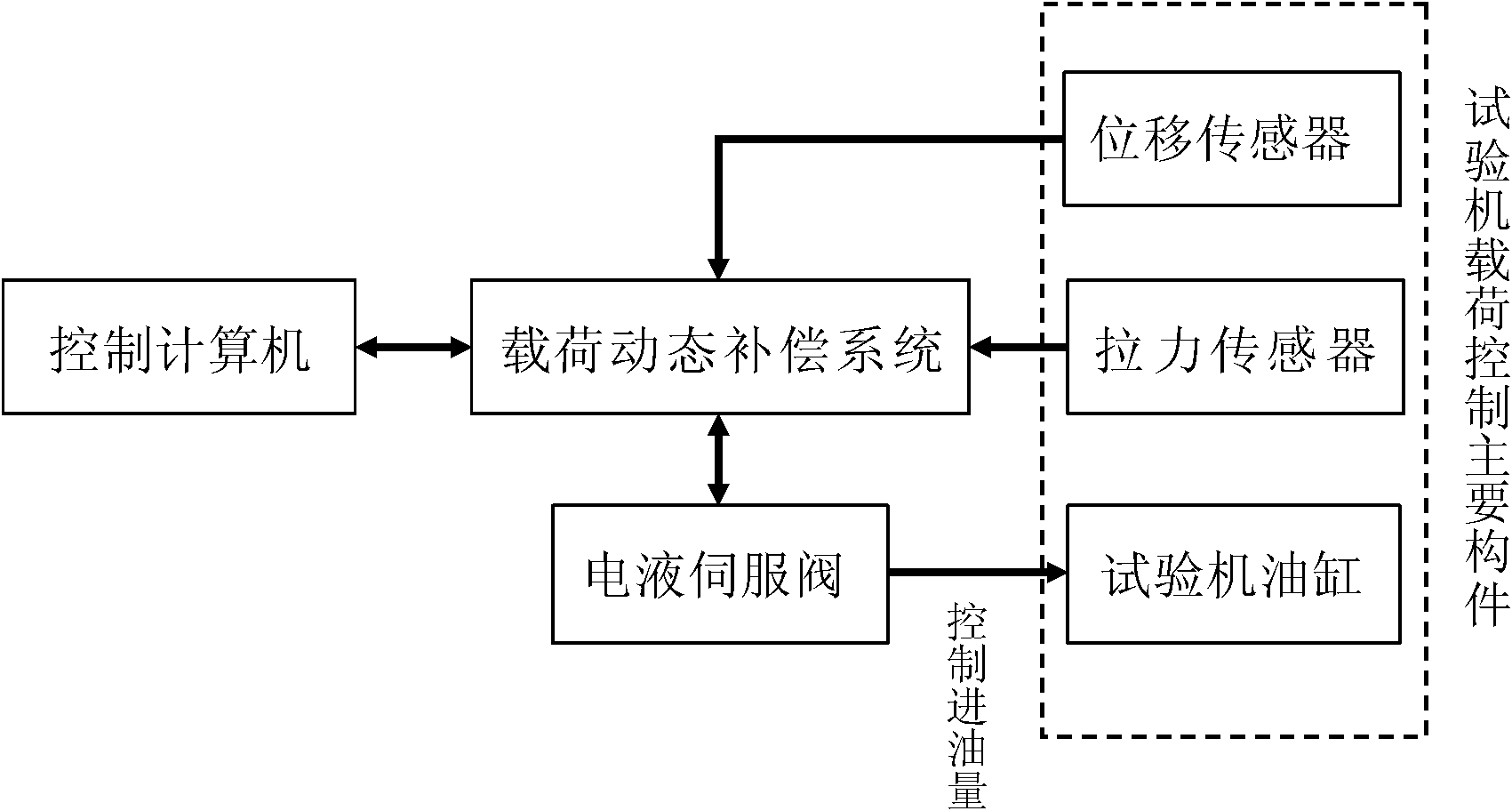

Method used

Image

Examples

example

[0033] The device of the present invention is used to test a kind of power equipment of cast aluminum alloy suspension wire clamp. When it is used to suspend the high temperature bearing performance of the wire on the iron tower, first remove other accessories of the suspension wire clamp, and only the main body is tested. according to Figure 6 Assembled and connected as shown, the upper pull rod 12 and the frame body 22 are connected by threads, the inner surface of the suspension wire clamp 26 is attached to the lower part of the frame body 22, and the lower rod 13 is connected to the two hanging ears of the suspension wire clamp through the bolt 25 27 connected. The lower half of the upper pull rod 12, the frame body 22, the suspension wire clamp 26 and the upper half of the lower rod 13 are all put into the high temperature box 2, and the upper and lower pull rods pass through the through holes with a diameter of Φ50mm on the upper and lower surfaces of the high temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com