Method for welding doubly clad optical fiber and photonic crystal fiber

A technology of photonic crystal fiber and double-clad fiber, which is applied in the coupling of optical waveguide, light guide, optics, etc., can solve the problems of high loss, high splicing loss value, mismatched outer diameter, etc., and achieve high-quality, low-loss splicing , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

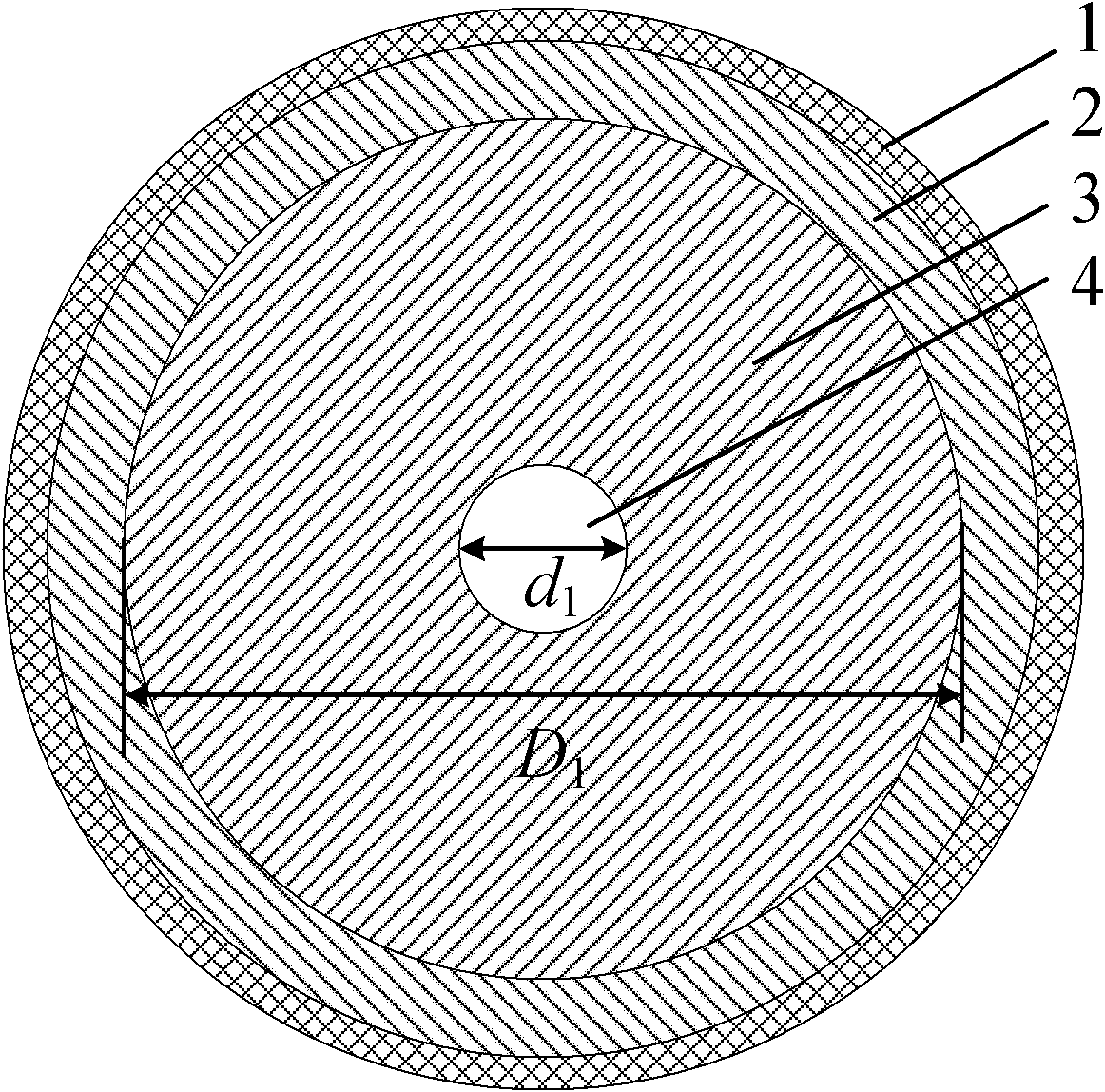

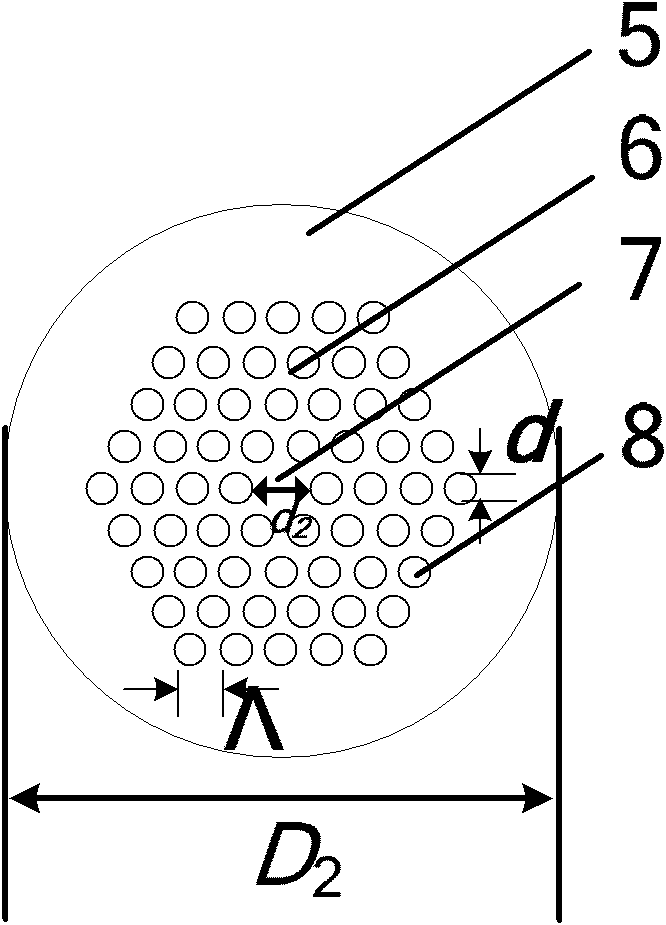

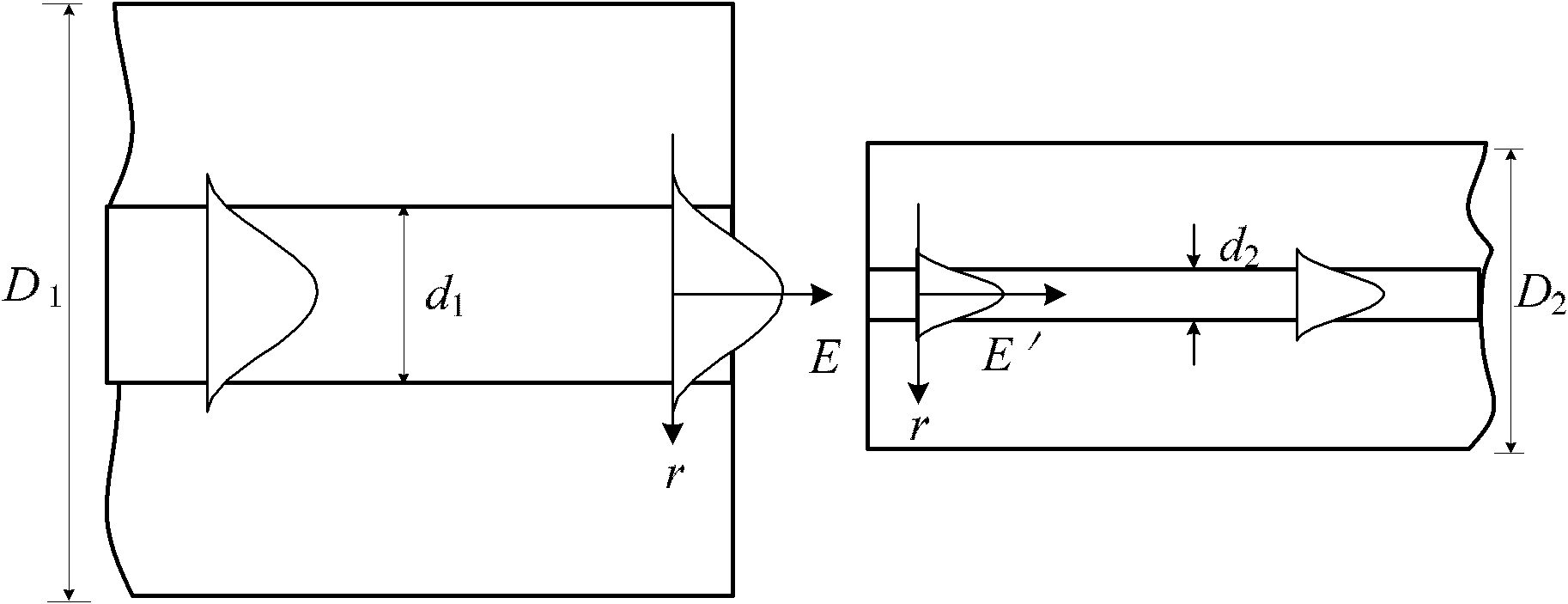

[0030] a kind of like figure 1 The shown double-clad optical fiber is composed of a protective layer 1 , an outer cladding 2 , an inner cladding 3 and a core 4 in sequence from outside to inside. The laser is transmitted in the fiber core 4, and the inner cladding 3 covered by the fiber core 4 is made of silica whose refractive index is smaller than that of the fiber core 4. The inner cladding 3 is the transmission channel of the pumping light, and its diameter is D 1 ; The outer cladding layer 2 covered by the inner cladding layer 3 is composed of a polymer with a smaller refractive index. The mode field diameter of double-clad fiber is generally all larger, and outer diameter is also bigger than common fiber and photonic crystal fiber, for example the double-clad fiber (Nufern company production, LMA-GDF-30 / 250 model) that present embodiment uses The outer diameter D 1 (that is, the diameter of the inner cladding 3) is 250 μm, the core diameter is 30 μm, and the mode fiel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com