Passive temperature compensation mechanism for optical instrument

A temperature compensation, optical instrument technology, applied in optics, instruments, optical components, etc., can solve problems such as the performance of optical instruments cannot be guaranteed, the surface accuracy of optical parts is reduced, and the imaging quality of optical systems is affected, and controllable design variables can be achieved. Multiple, simple structure, the effect of eliminating adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

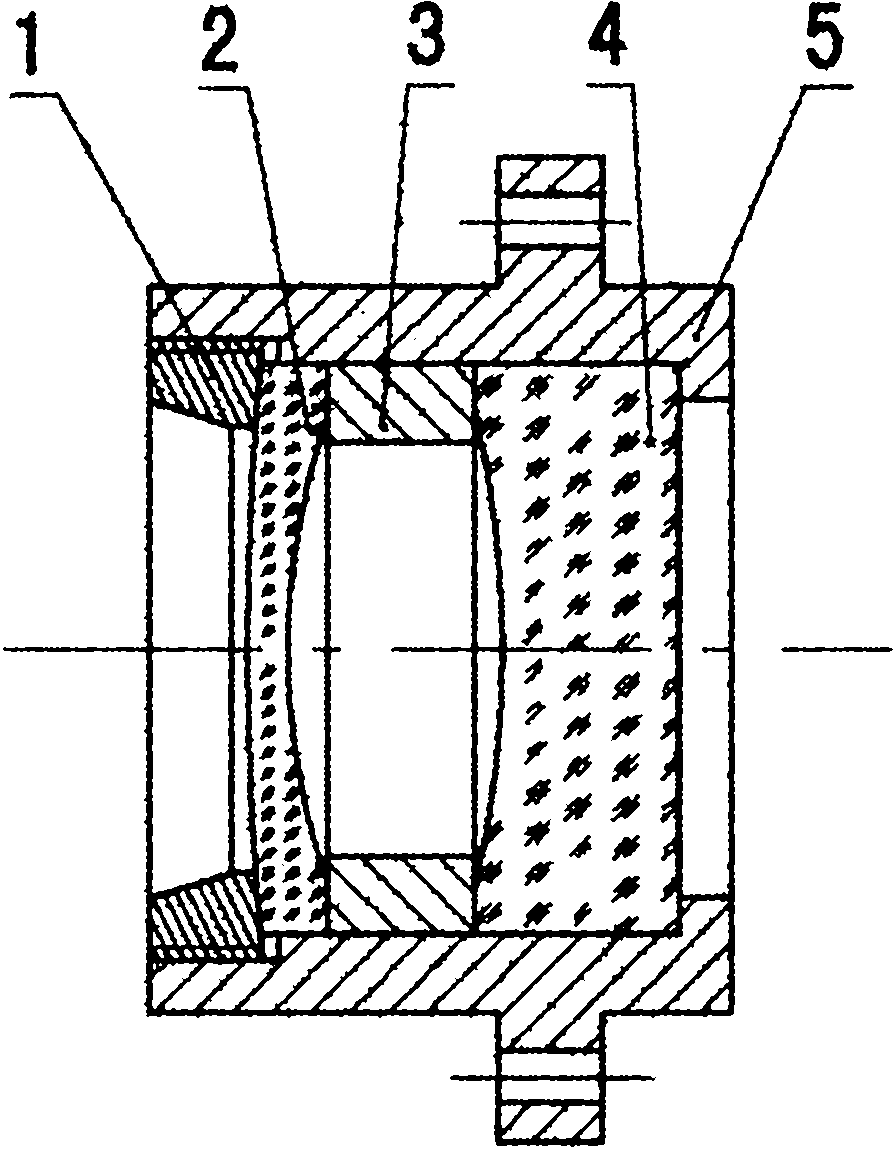

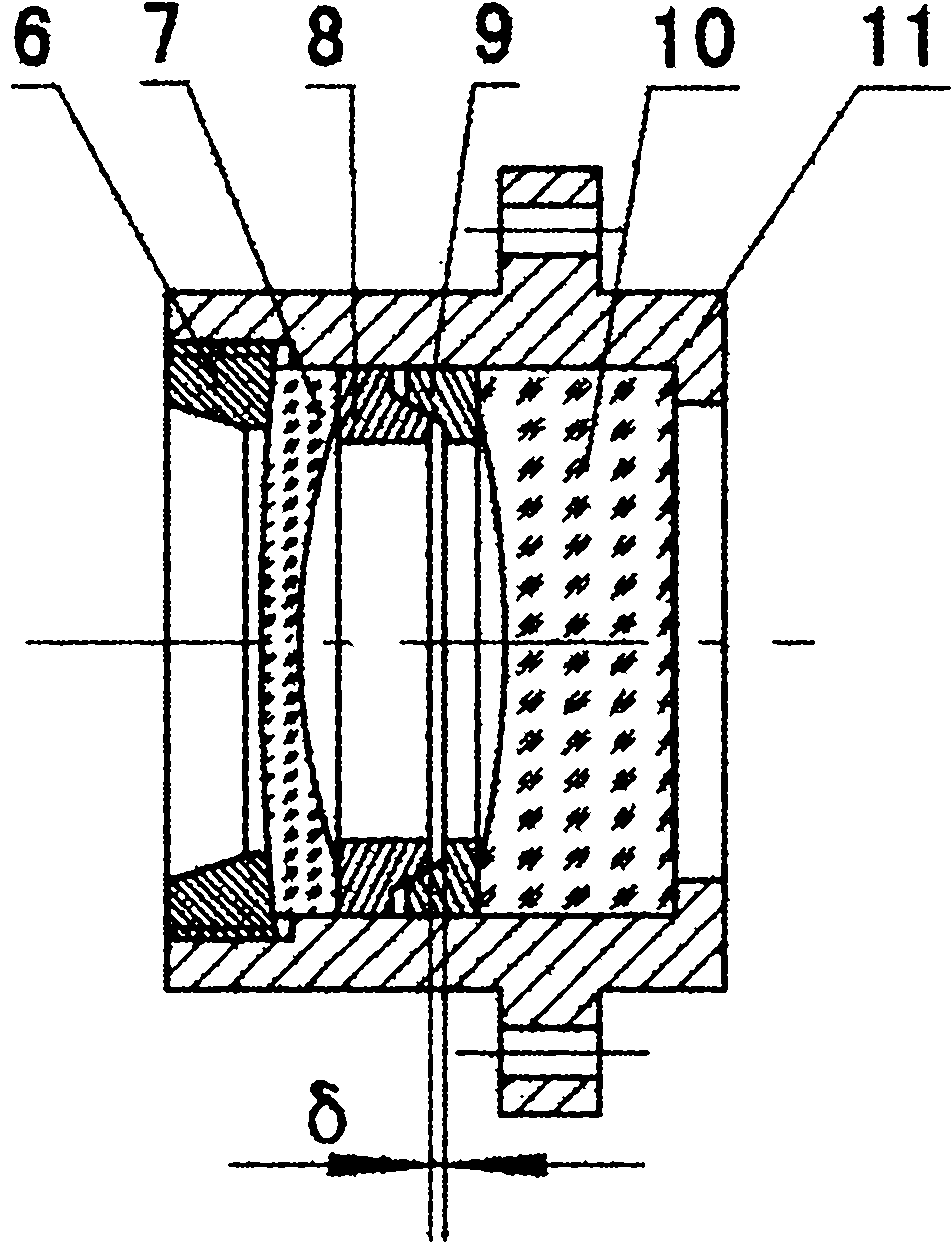

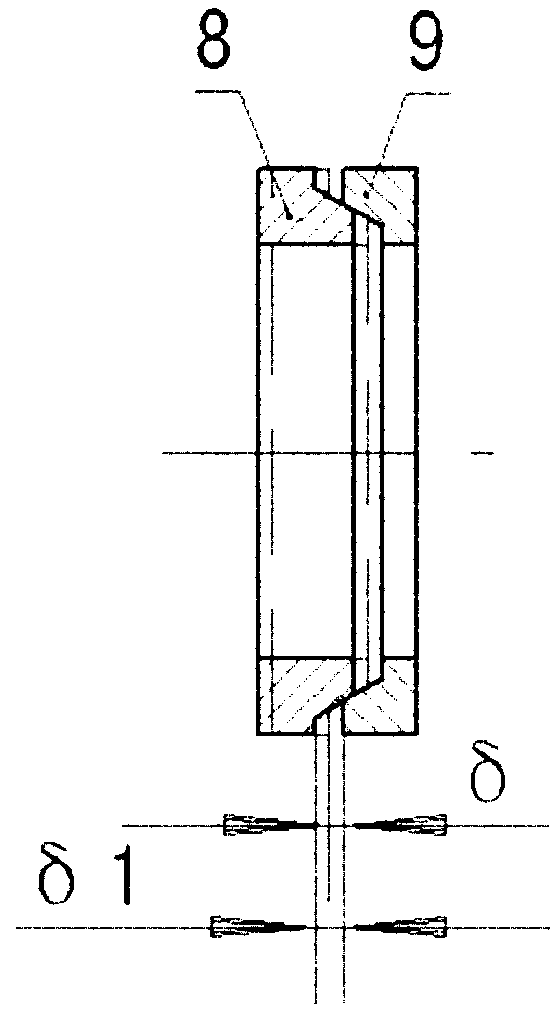

[0021] The present invention is figure 2 The shown structure is implemented, including the pressure ring 6, the first lens 7, the first spacer 8, the second spacer 9, the second lens 10, and the lens holder 11, where L, L 3 , L 4 , L 5 , C, C 3 , C 4 , C 5 It is fixed for a specific optical instrument, and α, C 1 , C 2 , L 1 , L 2 , D are design variables, and the specific implementation steps are as follows:

[0022] 1) Predetermine a wedge angle α between the spacers (30°1 , L 2 Contact the pitch diameter D with the two spacers;

[0023] 2) Select the material of the first spacer 8 and the second spacer 9, and C 1 >C 2 ;

[0024] 3) Calculate the axial gap β due to the difference in thermal expansion coefficient between the lens holder and the optical element when the temperature changes ΔT. The calculation formula is:

[0025] 4) Set Δδ equal to β, the wedge angle α can be calculated from formula (1);

[0026] 5) If the wedge angle α is slightly larger tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com