One-cycle controlled constant-power electronic ballast for high intensity discharge (HID) lamp and control method of electronic ballast

A single-cycle control, electronic ballast technology, applied in the use of electric light sources, electrical components, gas discharge lamps, etc., can solve problems such as affecting control accuracy, cumbersome calculation of constant power adjustment, and system oscillations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

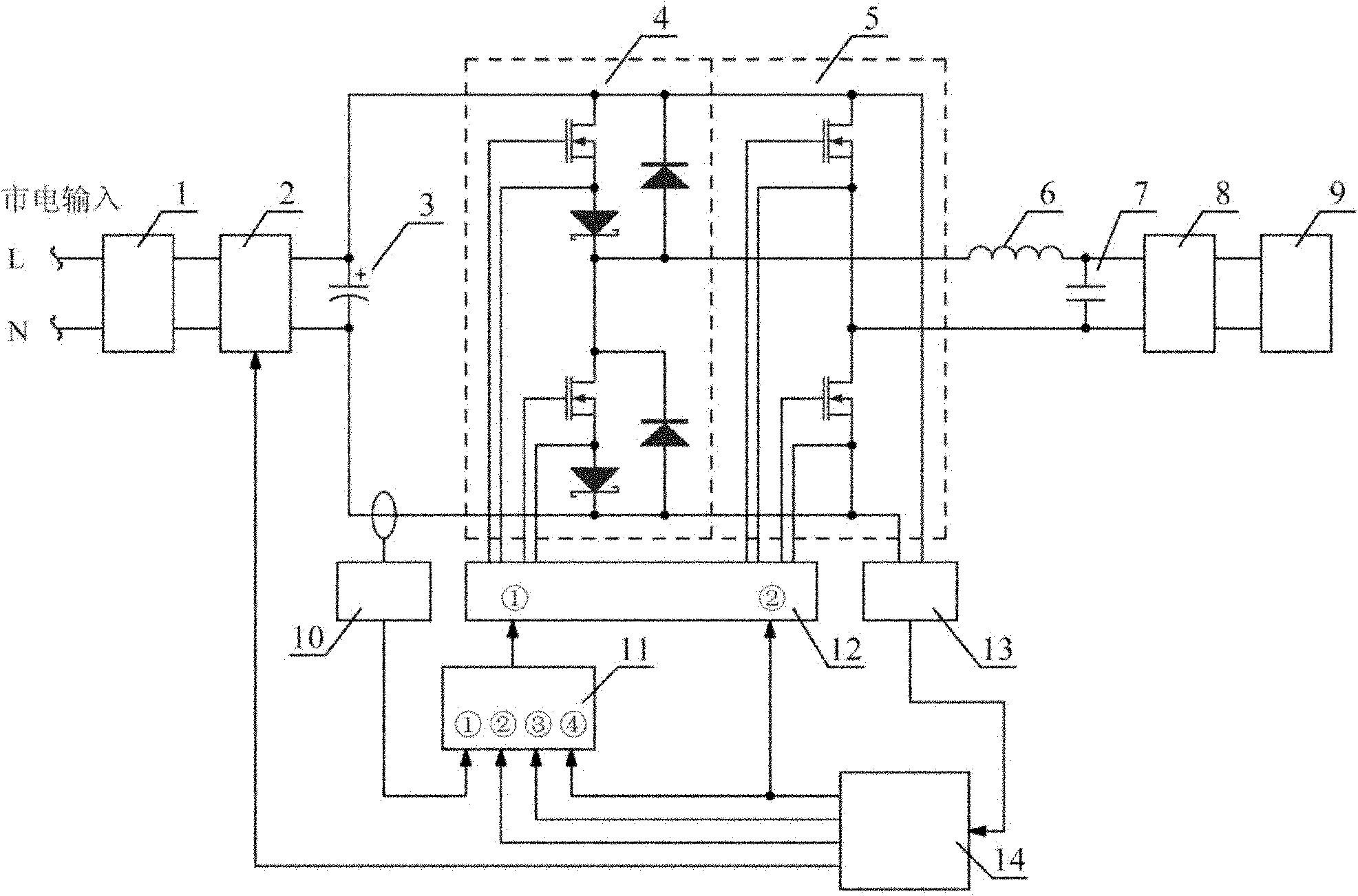

[0070] figure 1 It is a structural schematic diagram of the first embodiment of the single-cycle control constant power HID lamp electronic ballast.

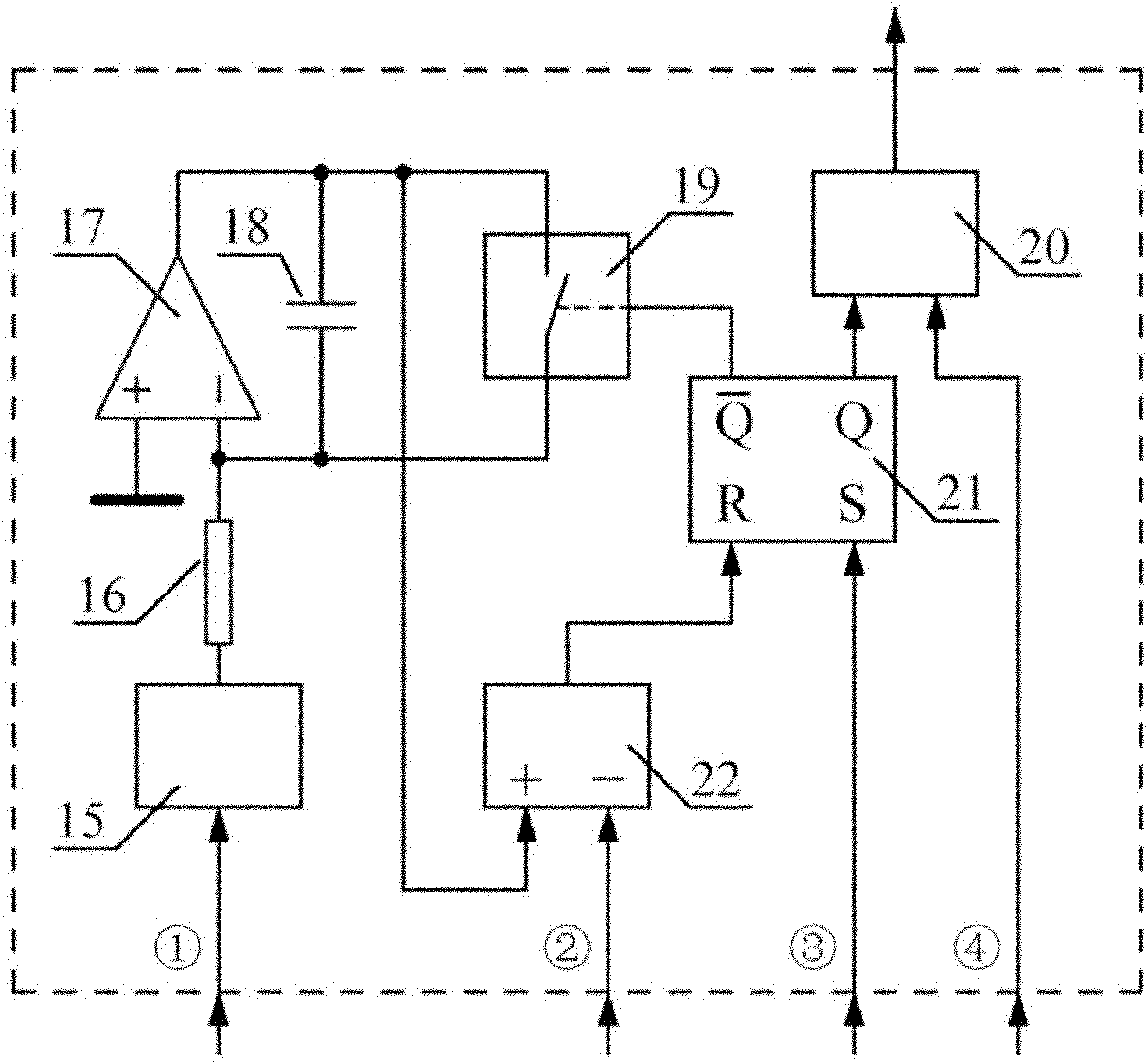

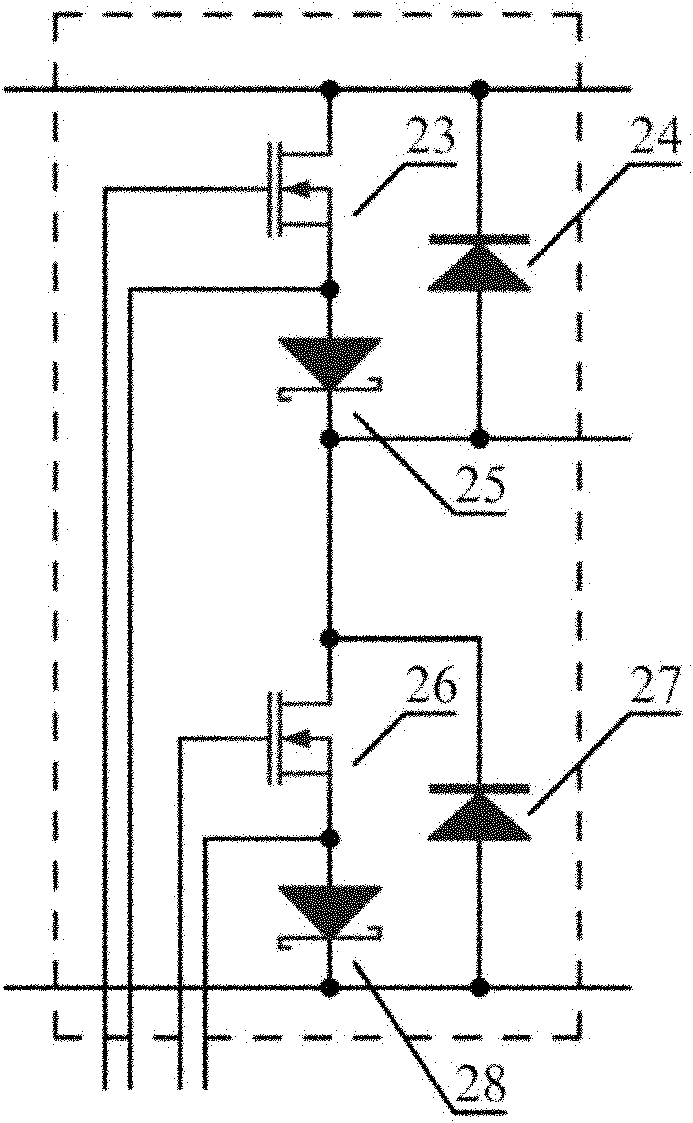

[0071] Such as figure 1 As shown, a single-cycle control constant power HID lamp electronic ballast is characterized in that it includes 4 high-frequency inverter half-bridges and 5 low-frequency inverter half-bridges, the 4 high-frequency inverter half-bridges and 5 low-frequency inverter half-bridges The inverter half-bridges share the same DC bus; 3 energy storage capacitors are connected between the two poles of the DC bus, and are connected to the output terminals of the 2 high power factor rectifier units; the input terminals of the 2 high power factor rectifier units are connected to 1 electromagnetic compatibility filter unit Output terminal, 1. The input terminal of the electromagnetic compatib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com