Hole type system and rolling process for super large diameter round steel production

A round steel rolling, super-large diameter technology, applied in the field of super-large diameter round steel production pass system and rolling process, can solve the problems of low production efficiency and high production cost, achieve straightness guarantee, improve dimensional accuracy and surface quality , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

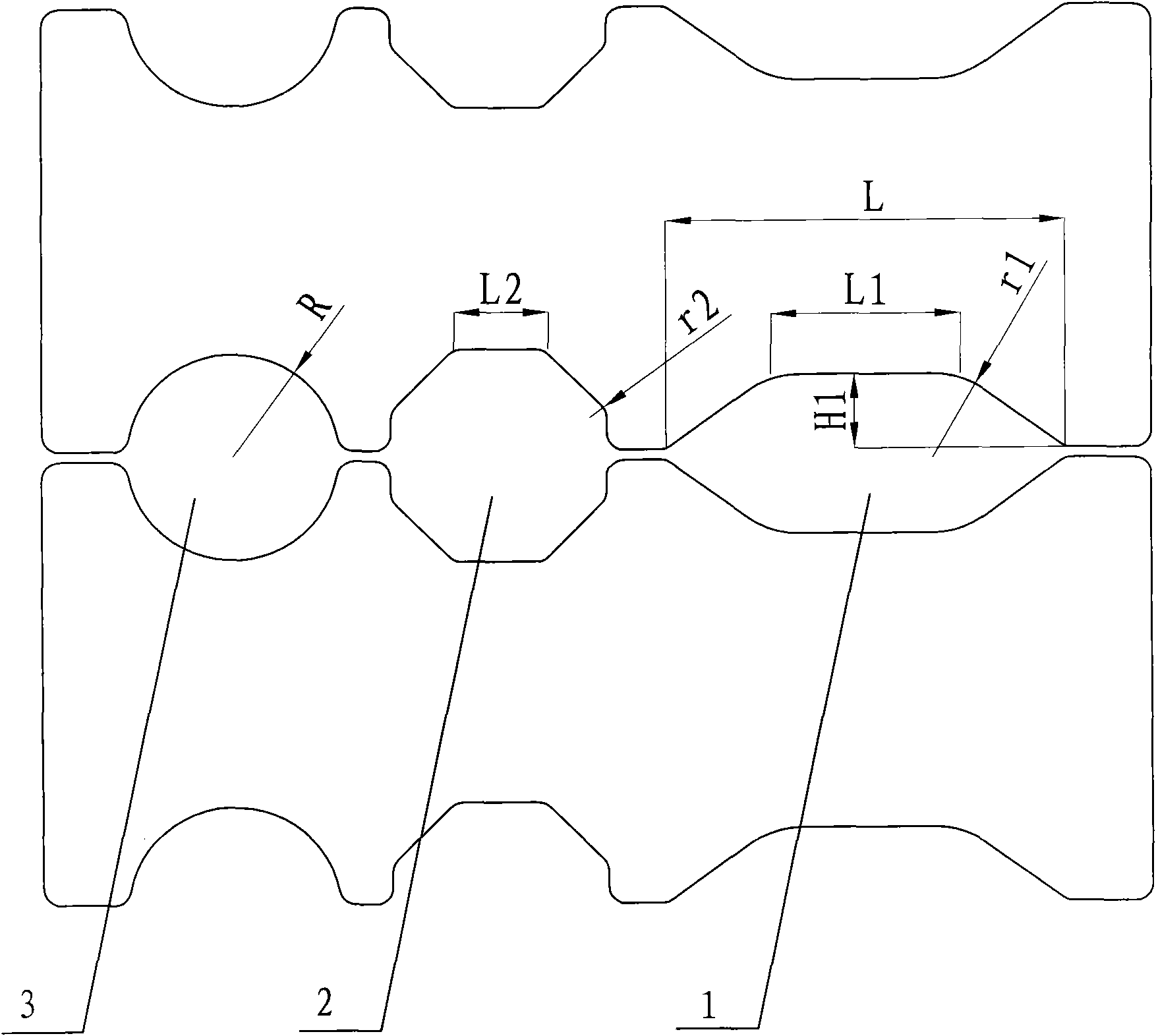

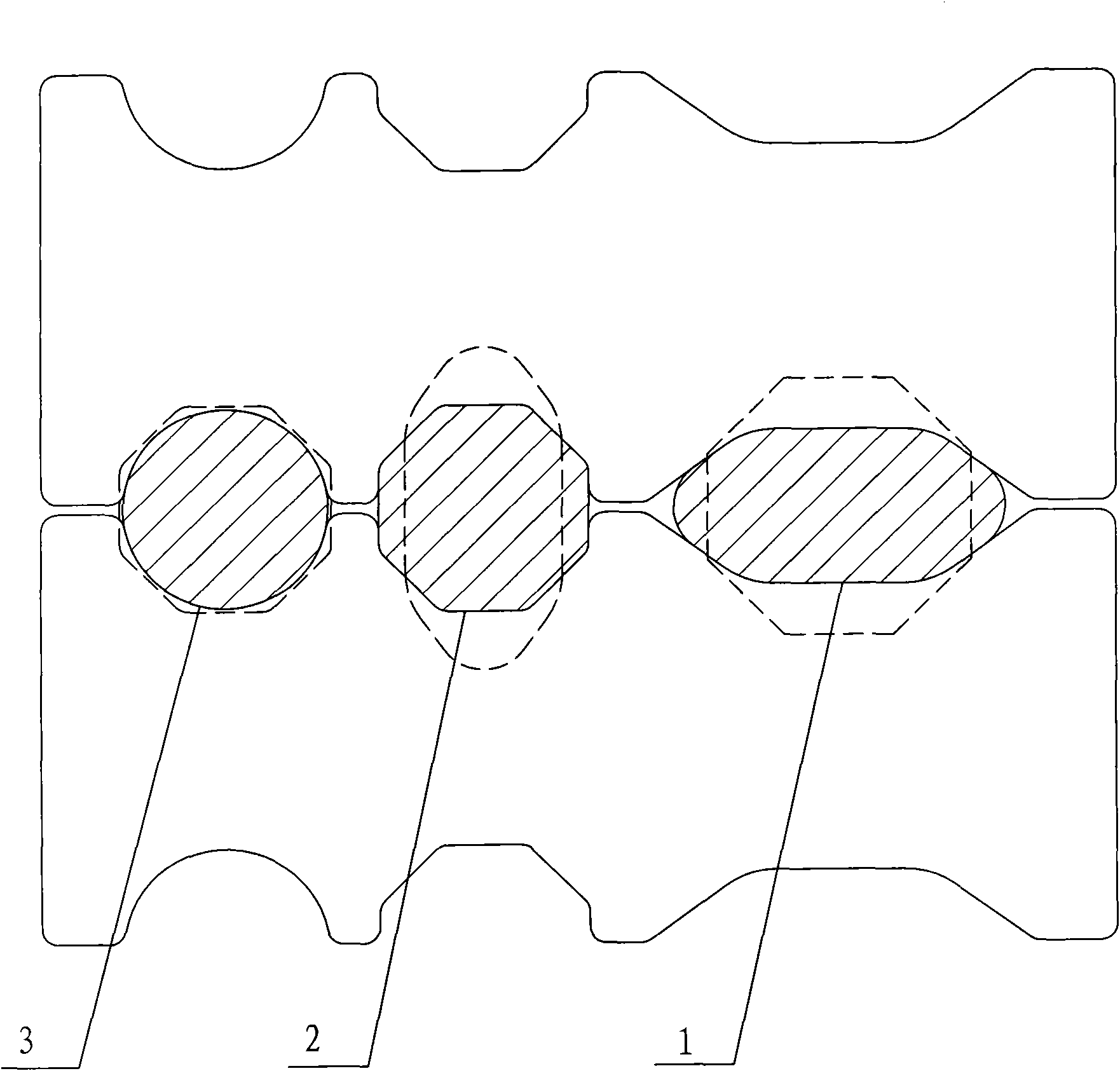

[0022] This embodiment describes the pass design and rolling process for the production of Φ660mm super large diameter round steel. The complete process is: steel billet-heating-flat hexagonal pass 1 rolling-octagonal pass 2 extension rolling-finished round Pass type 3: finishing rolling-straightening-cooling-slitting-finishing-storage. In this embodiment, an octagonal prism billet with a diagonal length of 1010mm is selected, the material of the billet is P91, the diameter of the round steel produced is Φ660mm, the diameter of the roll used is 1500mm, the speed of the roll is 15rpm, and the initial rolling temperature of the billet is about 1250°C . For the design of each pass on the roll, please refer to the attached figure 1 , and its relevant parameters are:

[0023] Flat hexagon pass pattern 1: the total length of the pass pattern L=1250mm; the length of the bottom edge of the pass pattern L1=700mm; the depth of the groove H1=330mm; the radius of the excessive arc r1=90...

Embodiment 2

[0035] This embodiment describes the roll design and rolling process for the production of Φ600mm super large diameter round steel. The complete process is: steel billet-heating-flat hexagonal pass 1 rolling-octagonal pass 2 elongation rolling-finished round hole Type 3 Finish rolling - Straightening - Cooling - Slitting - Finishing - Storage. In this embodiment, an octagonal steel billet with a diagonal length of 1010 mm is selected, and the material of the billet is P22. In this embodiment, the diameter of the roll used is 1500mm, the rotation speed is 30rpm, and the initial rolling temperature of the billet is about 1250°C. For the design of each pass on the roll, please refer to the attached figure 1 , and its relevant parameters are:

[0036] Flat hexagon pass pattern 1: total pass length L=1212mm; pass bottom edge length L1=630mm; groove depth H1=240mm; excessive arc radius r1=60mm.

[0037] Octagonal hole type 2: side length L2 = 250mm; transition arc radius r2 = 60m...

Embodiment 3

[0045] This embodiment describes the roll design and rolling process for the production of Φ350mm super large diameter round steel. The complete process is: steel billet-heating-flat hexagonal pass 1 rolling-octagonal pass 2 elongation rolling-finished round hole Type 3 Finish rolling - Straightening - Cooling - Slitting - Finishing - Storage. In this embodiment, an octagonal prism steel billet with a diagonal length of 1010mm is still selected, the material of the billet is P22, the diameter of the roll used is 1500mm, the rotational speed of the roll is 15rpm, and the initial rolling temperature of the billet is about 1250°C. For each pass system on the roll, please refer to the attached figure 1 , and its relevant parameters are:

[0046] Flat hexagon pass pattern 1: the total length of the pass pattern L=1230mm; the length of the bottom edge of the pass pattern L1=660mm; the depth of the groove H1=150mm; the radius of the excessive arc r1=35mm.

[0047] Octagonal hole ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com