Polymer-modified waterproof mortar

A waterproof mortar and polymer technology, applied in the chemical field, can solve the problems of poor waterproof effect of waterproof materials, and achieve the effects of improving the compactness of mortar, improving construction performance, and long life cycle

Inactive Publication Date: 2011-05-25

上海雅和高分子材料有限公司

View PDF0 Cites 28 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The object of the present invention is to provide a kind of polymer modified waterproof mortar, described this kind of polymer modified waterproof mortar will solve the technical problem in the prior art that the waterproof effect of the waterproof material used for building seepage is not good

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

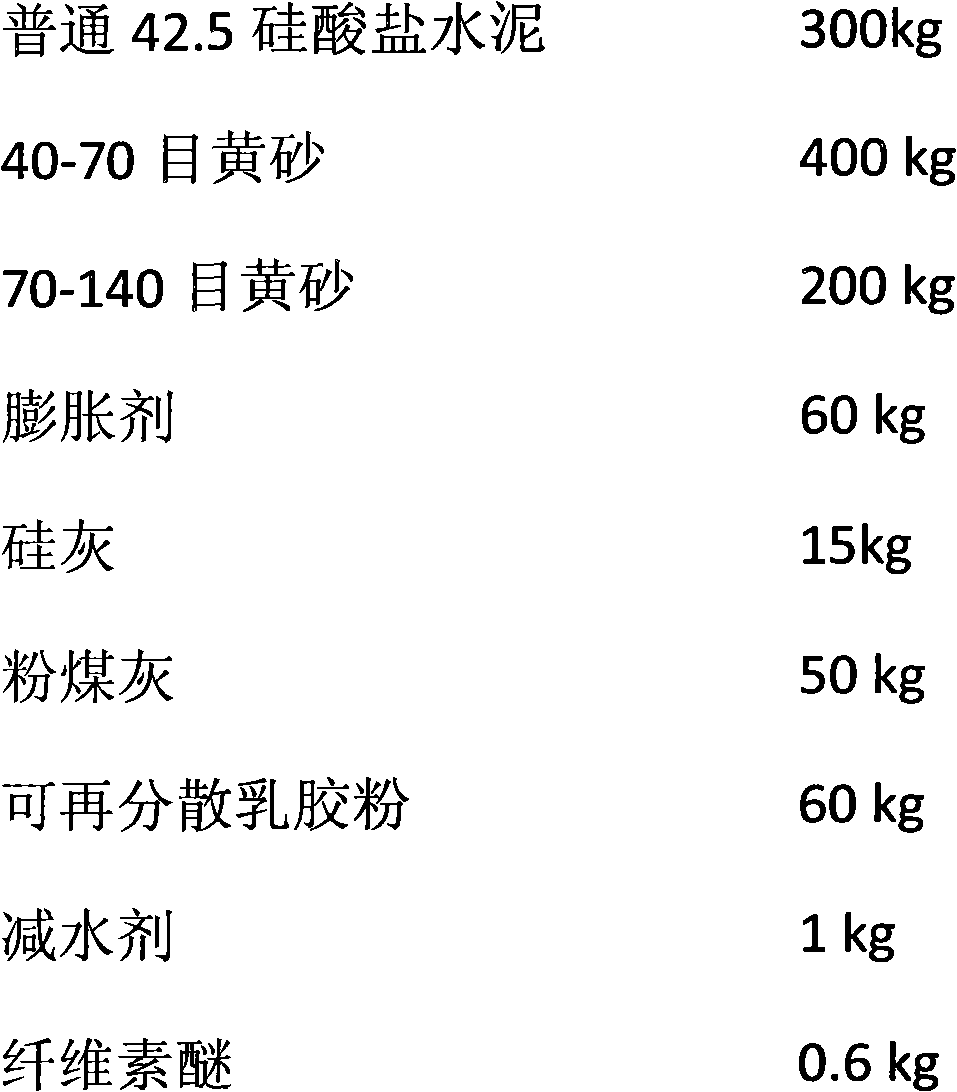

[0025]

[0026] Mix the above raw materials in a mixer for 10 minutes to make a dry powder mortar, add an appropriate amount of water and stir to put it into use. The waterproof mortar is tested according to JC / T984-2005. The 7-day impermeability pressure is above 1.5Mpa, and the bonding strength with the cement base surface is above 1.6Mpa. It also has excellent flexibility.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Login to View More

Abstract

The invention belongs to the field of chemistry, and provides a polymer-modified waterproof mortar, which comprises portland cement, graded sand, redispersible emulsion powder, water reducer, water-retaining agent, swelling agent and active filler. In the invention, the redispersible emulsion powder is used for sealing mortar pores after being formed into a film, so as to prevent water from permeating into channels and make mortar have high bonding force and flexibility. The added active filler in the invention can improve the solidity and construction performance of the mortar, and the added swelling agent can counteract part of the dry shrinkage stress of the mortar, optimize the grade of sands and improve the compactness of the mortar. The waterproof mortar, which have high-strength, can be widely used for waterproof construction in walls, toilets, basements, and other places, and has the characteristics of convenient use, wide application range, high durability, long service period and the like.

Description

Technical field: [0001] The invention belongs to the field of chemistry, and in particular relates to a polymer-modified waterproof building material, in particular to a polymer-modified waterproof mortar. Background technique: [0002] Building leakage mainly includes roofs, toilets, balconies, floors, exterior walls, basements, pools, trenches, etc., and has always been a major problem affecting the quality of living. Building waterproof technology can be divided into two categories: rigid waterproof and flexible waterproof according to the physical properties of the materials used. Flexible waterproofing mainly uses polymers as the main carrier, including various coiled materials, coatings, sealants, etc., and is the most important waterproofing measure traditionally. The physical properties of such materials and the main structure of the building are very different, and there are generally unsynchronized service life, Difficulties such as easy separation during use, lea...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B28/04C04B14/06C04B18/08C04B111/27

CPCC04B28/04Y02W30/91C04B14/06C04B18/08C04B20/0096C04B22/008C04B24/26C04B24/2641C04B24/383C04B2103/0057C04B2103/302C04B2103/304

Inventor 苗永志张华鸣陈国强

Owner 上海雅和高分子材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com