Konjak ceramide and extraction method thereof

A technology of ceramide and extraction method, which is applied in the field of konjac ceramide and the extraction and separation of ceramide from by-products and wastes of konjac, can solve the problems of lack of ceramide and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

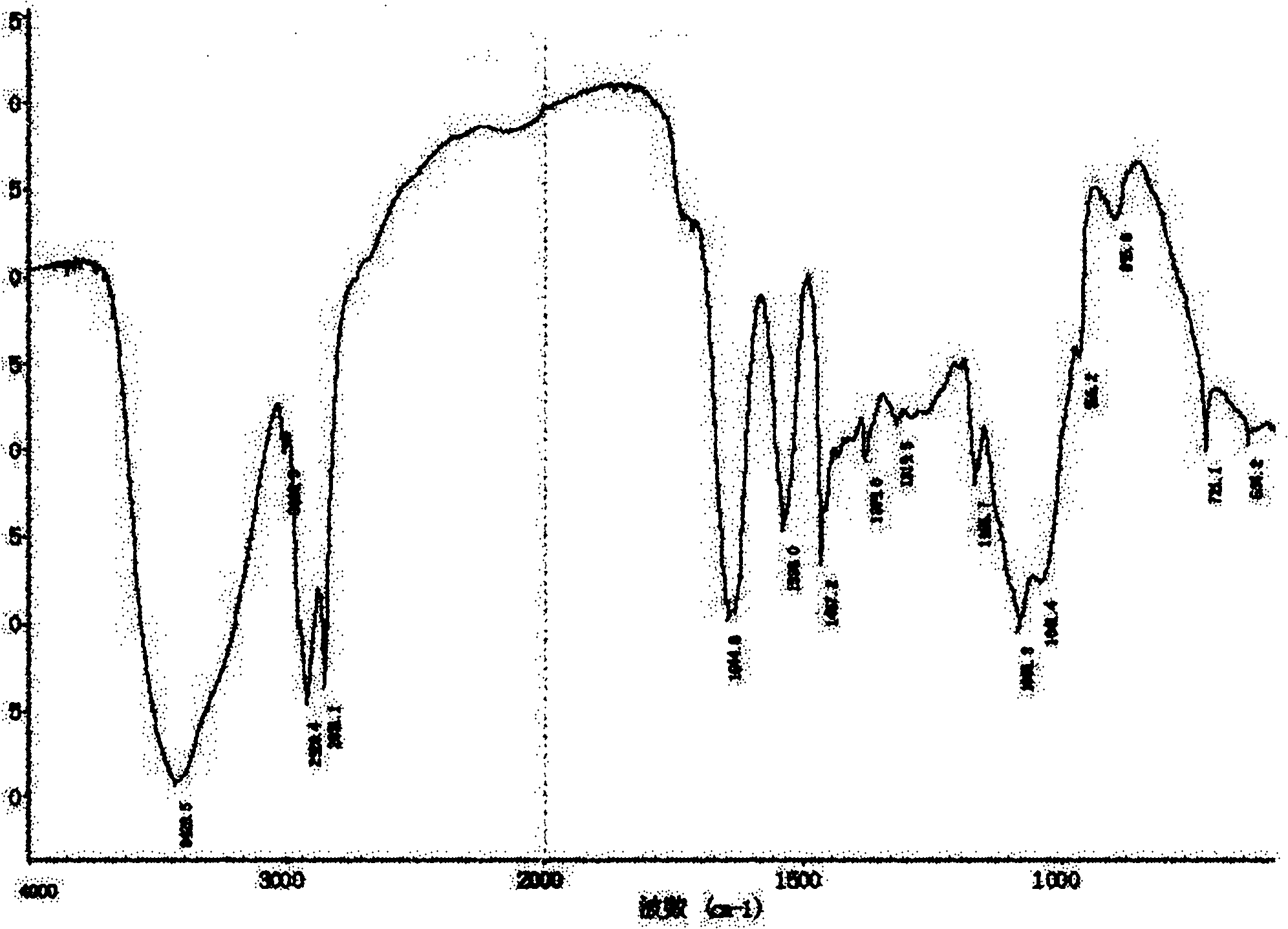

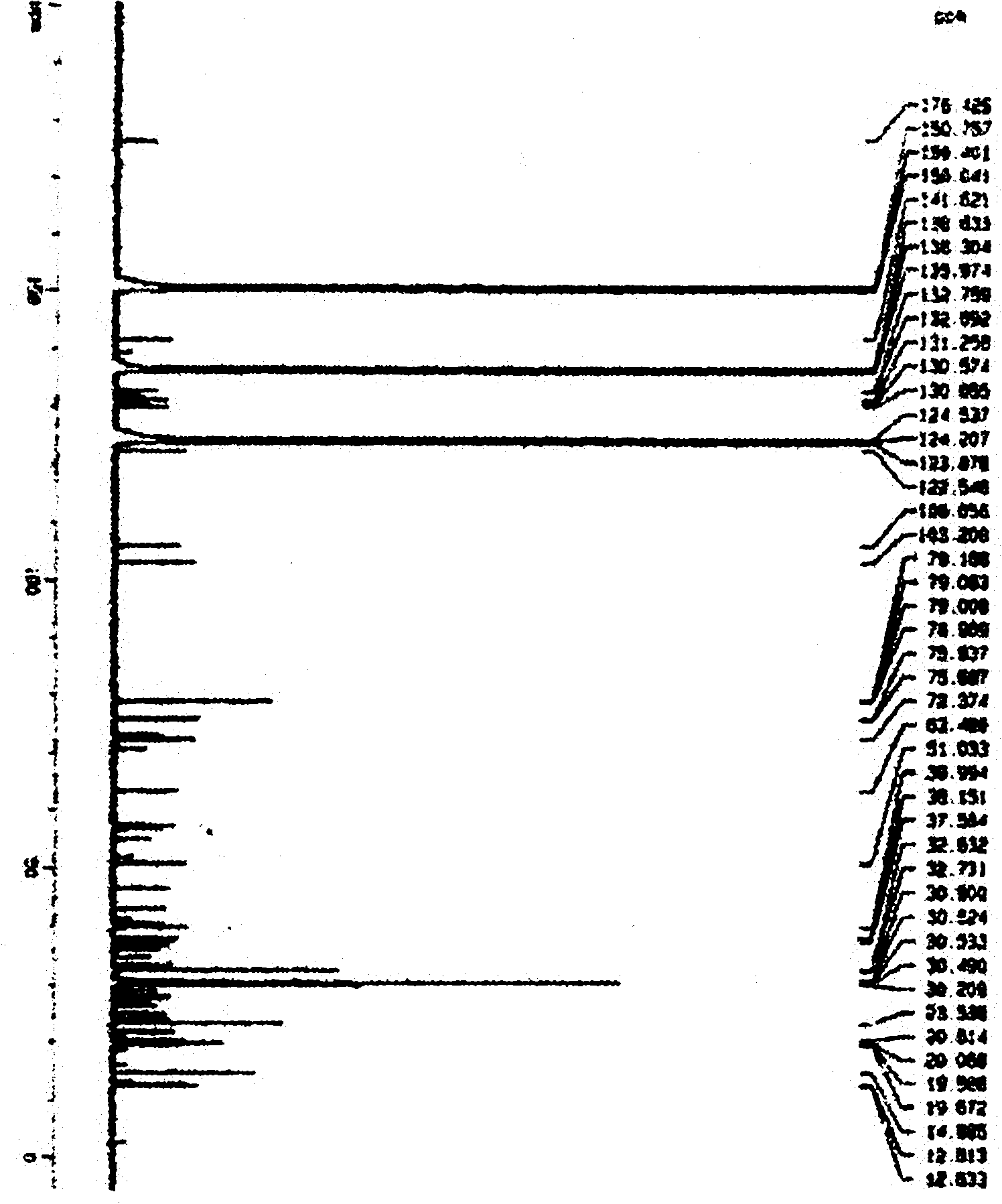

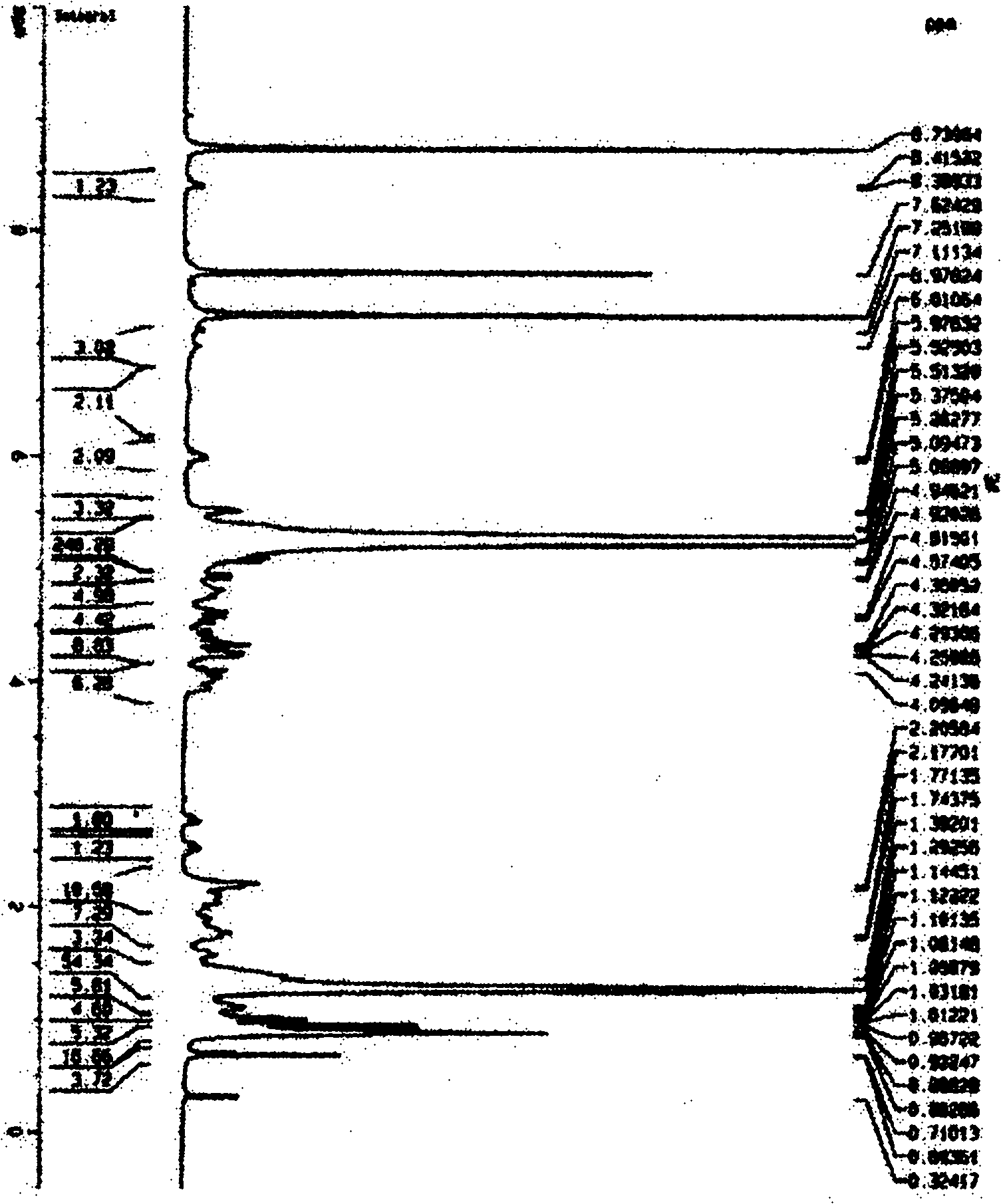

Image

Examples

Embodiment 1

[0033]Weigh 20.0 kg of flying powder, add it into a reaction tank equipped with 80 liters of 45% (V / V) ethanol while stirring at room temperature, stir while soaking, the rotating speed is 30 rpm, leaching for 2 hours, 1200 rpm / separation After 20 minutes, the reaction mixture was transferred to a 200-mesh cloth bag, pressed to dryness with a hydraulic press, and the extruded solution was recovered and the above leaching steps were repeated three times (the residual dry matter after the extruded solution was recovered, vacuum dried and recycled); Press out the solution and transfer it to a distillation recovery device, recover ethanol under the condition of normal pressure and 70-100°C for later use, slip out the residual liquid after ethanol, and collect the oil phase in layers; concentrate the water phase under reduced pressure to Brix The sugar content is 50 degrees, and then extracted and purified with ethyl acetate, the oil phase is collected, and all the oil phases are co...

Embodiment 2

[0035] Weigh 20.0 kg of fly powder, add it into a reaction tank equipped with 50 liters of 70% (V / V) ethanol while stirring at room temperature, extract for 1 hour, stir while soaking, the rotating speed is 120 rpm, 1200 rpm / separation After 20 minutes, the reaction mixture was transferred to a 300-mesh cloth bag, pressed to dryness with a hydraulic press, and the extruded solution was recovered and the above leaching steps were repeated three times (the dry matter after the extruded solution was recovered, vacuum dried and recycled); Take out the solution and transfer it to a distillation recovery device, recover the ethanol under reduced pressure and 70-100°C for later use, slip out the residual liquid after the ethanol, and collect the oil phase by standing and layering; freeze-dry and concentrate the water phase to 50 degrees Brix , and then extracted and purified with ethyl acetate, the oil phase was collected and all oil phases were combined, and concentrated to dryness t...

Embodiment 3

[0037] Weigh 20.0 kg of fly powder, add 50 liters of 85% (V / V) ethanol to the reaction tank while stirring at room temperature, stir while soaking, the rotating speed is 50 rpm, leaching for 1.5 hours, 1200 rpm / centrifugation for 20 minutes , and then transferred to a 200-mesh cloth bag, pressed dry with a hydraulic press, recovered the extruded solution and repeated the above leaching steps three times; combined the recovered extruded solution and transferred it to a distillation recovery device, and recovered it under normal pressure and 70-100°C Ethanol, the residual liquid after slipping out of ethanol, let stand to separate and collect the oil phase; lyophilize and concentrate the water phase to 50 degrees Brix, then extract and purify with ethyl acetate, collect the oil phase and combine all the oil phases, and concentrate to Dry to obtain 382.0 g of dark brown paste. Dissolve the dark brown paste substance in 1000 milliliters of 70% (V / V) ethanol, remove solid impuritie...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap