Transparent anti-fog film based on one or serveral graphene layers

A layered graphene, anti-fog film technology, applied in other chemical processes, chemical instruments and methods, etc., can solve problems such as inability to be widely used in daily life, complex devices, and poor effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

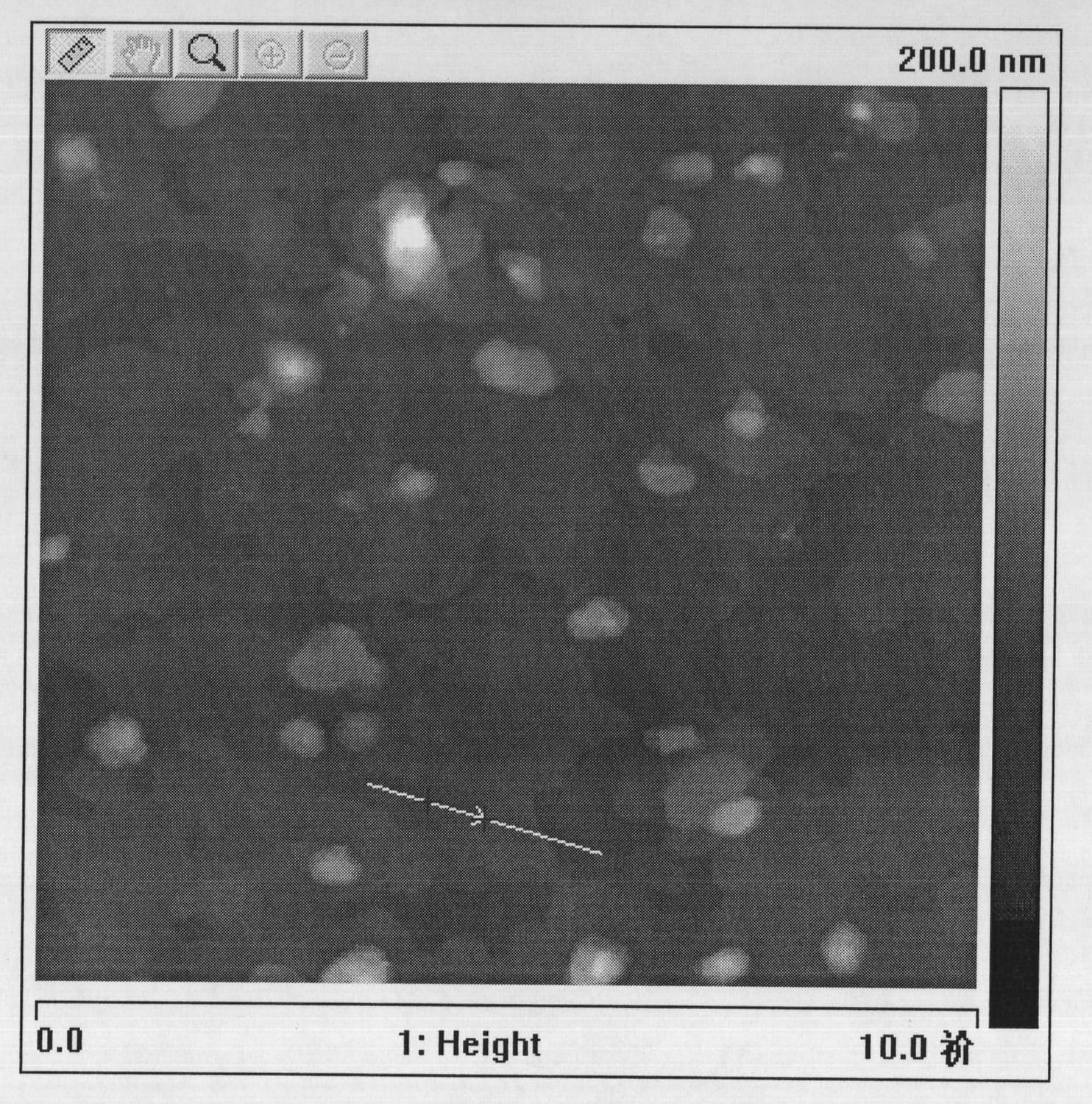

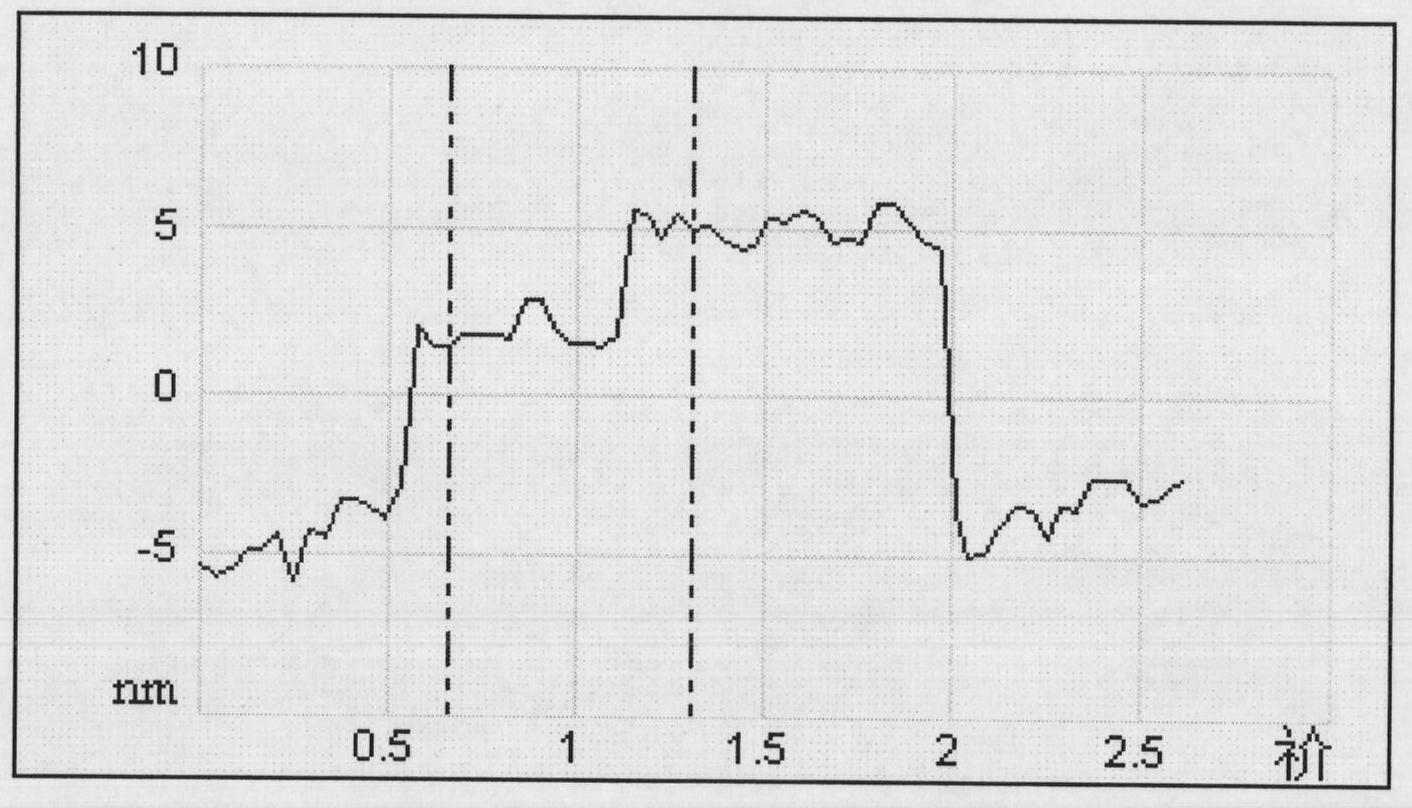

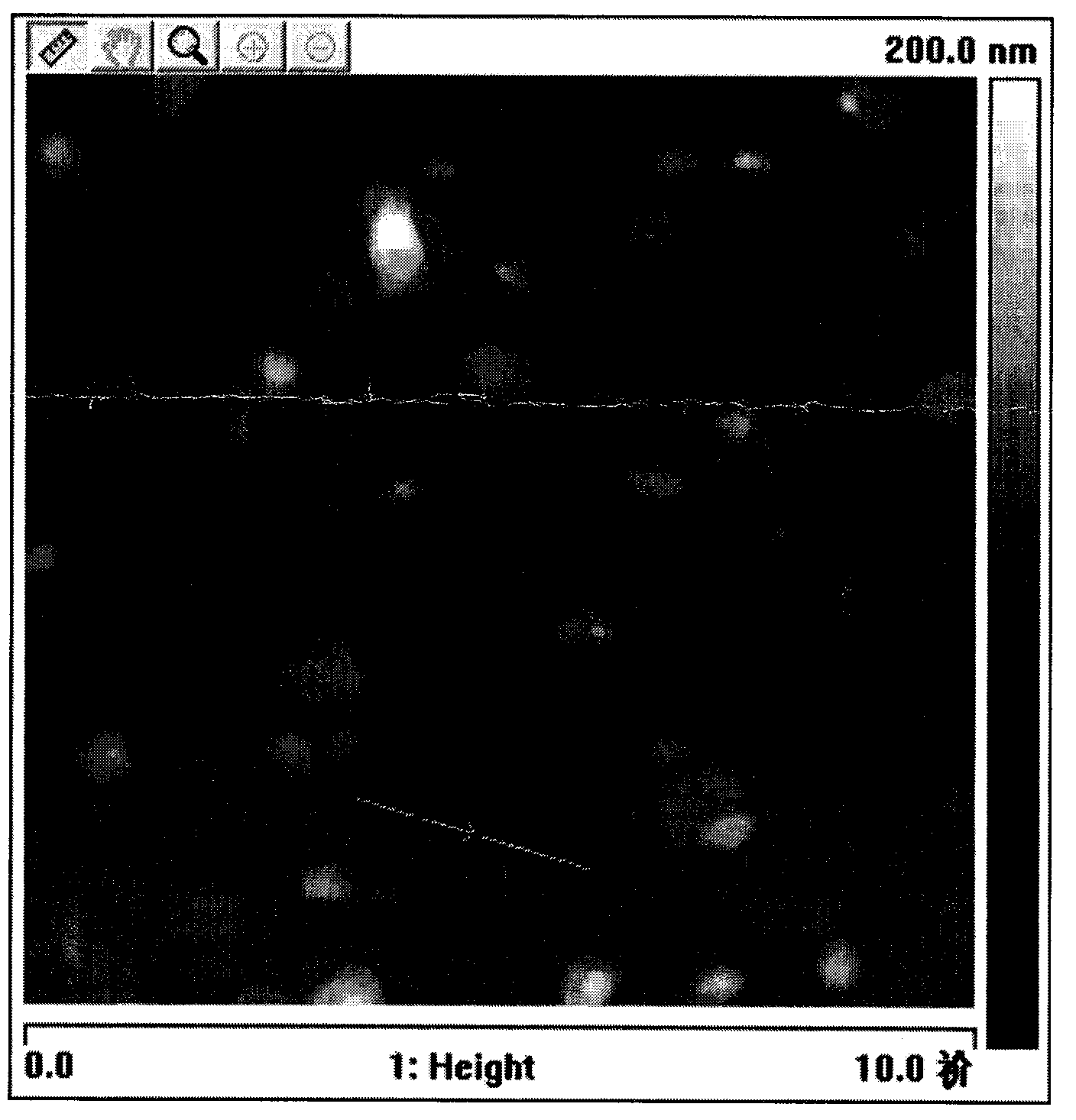

Image

Examples

Embodiment Construction

[0021] Further illustrate content of the present invention below in conjunction with example:

[0022] Case number one:

[0023] The preparation of graphene: using the improved Hummer method in 98% concentrated sulfuric acid, cooling at low temperature, adding a certain amount of natural flake graphite, NaNO 3 and KMnO 4 , the temperature of the reaction solution is controlled at 0-10°C, and the high-temperature reaction is carried out after stirring for 5 hours. The temperature of the reaction solution does not exceed 100°C, and the stirring is continued for 30 minutes. 2 o 2 , filtered while hot, and the filtered product was fully washed with deionized water until there was no SO in the filtrate. 4 2- , and then dried, ground and sieved, and rapidly heat-treated at 1200°C to obtain single-layer or several-layer graphene flakes. The prepared single graphene has an area of 100 square nanometers to 10 square micrometers, a thickness of 0.3-3nm, and a specific surface area ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com