Horizontal well high-pressure resistant packer for reservoir transformation

A technology for reservoir stimulation and horizontal wells, which is used in the field of downhole packers, packers with self-expanding rubber cylinders in contact with water and oil, and can solve the problem of high requirements on well diameter size, complex structure, and failure of seat sealing, etc. problems, to reduce risks, simplify mechanical components, and work reliably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

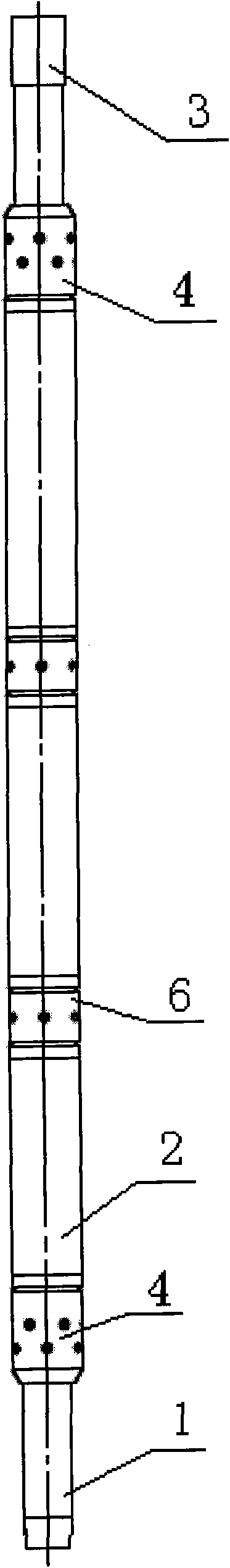

[0032] Embodiment 1: Taking a horizontal well high pressure resistant packer for reservoir stimulation as an example, the present invention will be further described in detail.

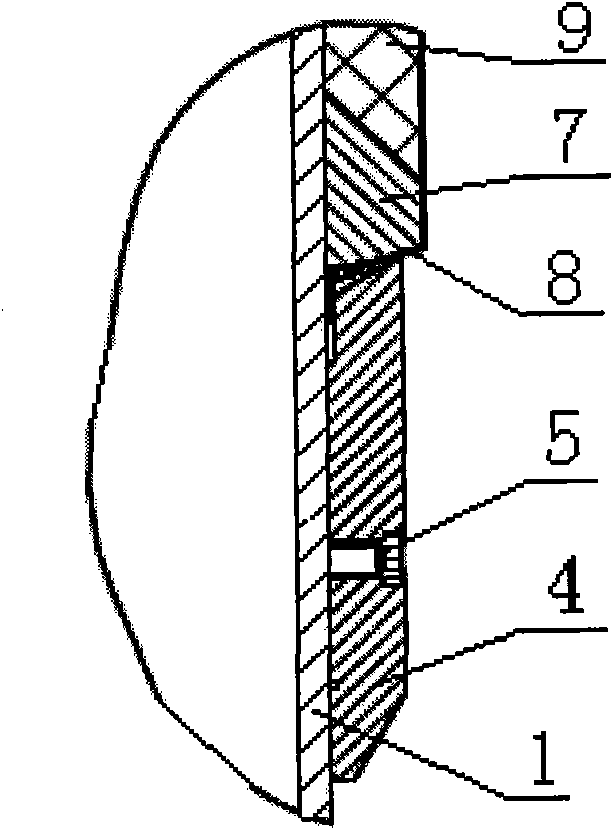

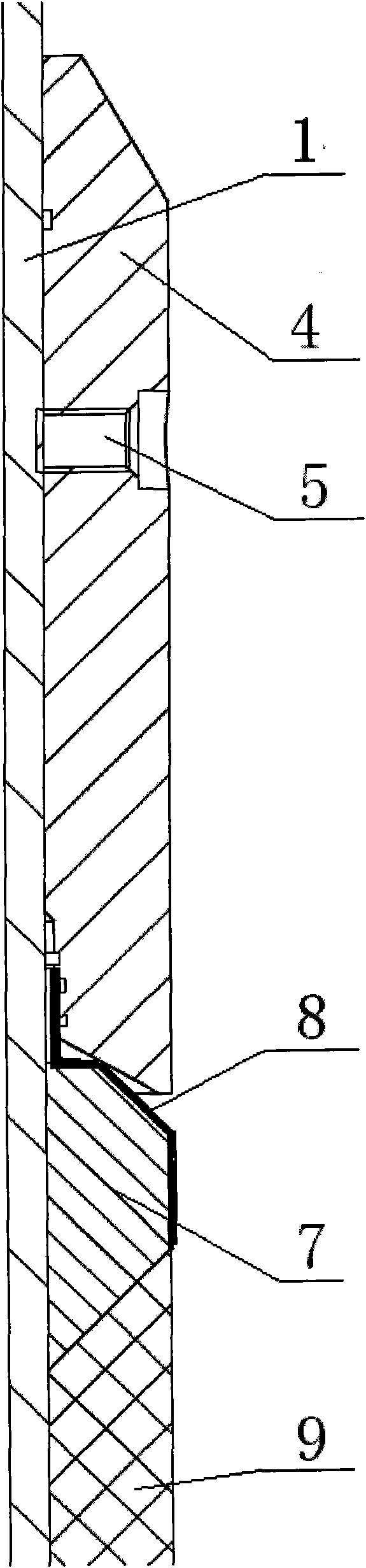

[0033] refer to figure 1 . A horizontal well high-pressure resistant packer for reservoir stimulation mainly consists of a pipe body 1, a self-expanding rubber cylinder 2, a collar 3, a limit ring 4, a fastening bolt 5 and an intermediate retaining ring 6. The pipe body 1 adopts 51 / 2" API oil pipe, the outer diameter of the pipe body 1 is 139.7mm, and the length is 6400mm. Both ends of the pipe body 1 have external threads, and one end of the pipe body 1 is connected with a coupling 3 through threads. The expansion rubber cylinder 2 is composed of a self-expanding rubber cylinder back pressure ring 7, a metal ring 8 and a self-expanding rubber cylinder body 9.

[0034] Three sections of self-expanding rubber cylinders 2 are molded and vulcanized on the outer wall of the pipe body 1 . refer to Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com