Biomass energy combustor

A biomass energy and burner technology, applied in the direction of biofuels, combustion methods, combustion equipment, etc., can solve the problems of low charcoal quality and inability to produce charcoal in the middle, so as to increase the contact surface, improve the combustion effect, and improve the product quality. The effect of carbon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

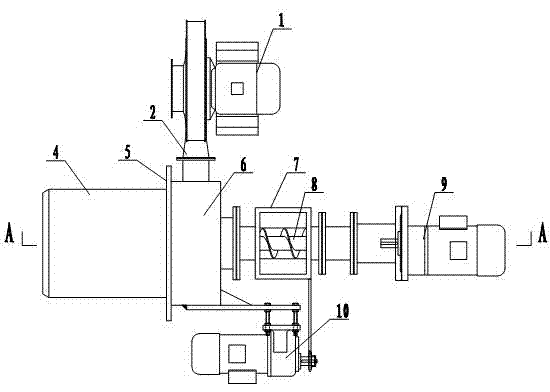

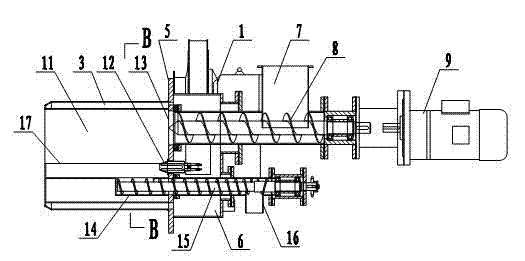

[0030] Embodiment 1: a kind of biomass energy burner, such as Figure 1 to Figure 4 shown.

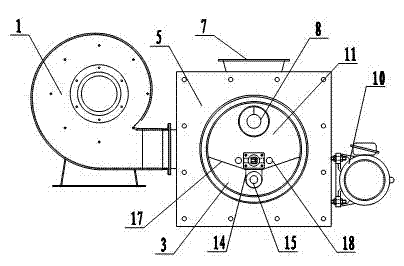

[0031] This device comprises burner base body 4, and burner base body 4 is horizontal cylinder type, as figure 1 , figure 2 , image 3As shown, the burner base 4 has a double-layer structure, the inner layer is the combustion chamber 11, the outer layer is the secondary air distribution chamber 3, the secondary air distribution chamber 3 surrounds the outside of the combustion chamber 11, the top of the combustion chamber 11 is an arc top, and passes through The top wall of the combustion chamber separates the combustion chamber 11 from the secondary air distribution chamber 3, and the bottom of the combustion chamber 11 is provided with an air distribution plate 17 and is separated from the secondary air distribution chamber 3 by the air distribution plate 17, as Figure 4 As shown, the air distribution plate 17 is provided with an air distribution hole 19 . Such as image 3 As ...

Embodiment 2

[0034] Embodiment 2: A kind of biomass energy burner that preheats combustion-supporting air, such as Figure 5 , Image 6 shown. A layer of preheating chamber 20 is arranged on the outer periphery of the burner base 4 , and a plurality of cold air inlets 21 are opened on the circumference of the preheating chamber 20 , and the preheating chamber 20 is connected with the fan air inlet 22 . The rest of the structure in this embodiment is the same as in Embodiment 1.

[0035] Due to heat conduction, the outer wall of the burner base 4 usually has a higher temperature, even reaching more than 100 degrees. The combustion-supporting air enters the preheating chamber 20 from the cold air inlet 21, and the heat of the outer wall of the burner base 4 is used for preheating. From the fan 1 to the air distribution chamber 6, not only the heat lost during combustion is reused, but also the heat insulation effect between the burner base 4 and the environment is achieved.

[0036] The w...

Embodiment 3

[0037] Embodiment 3: a kind of feed compression biomass energy burner, such as Figure 7 shown. The pitch of the feeding auger 8 helical blades decreases continuously with the conveying direction, and the ratio of the pitches at both ends is 4:1. The rest of the structure of this embodiment is the same as that of Embodiment 1.

[0038] When the biomass fuel to be burned is bamboo chips, wood chips, straw, etc., if the feeding auger with equal pitch is used, because the fuel is relatively loose, there is a large gap in the fuel delivery process, and the smoke in the combustion chamber is easy to flow from The gap overflows, and because the fuel is entrapped with air, the fuel is easily ignited at the inlet of the combustion chamber, and burns all the way to the hopper, causing serious consequences. Therefore, when using such loose fuel, it is necessary to The fuel is compressed to make the fuel structure more compact, and at the same time, the air trapped in the fuel gap is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com