Indirect air-cooling control system of surface condenser

A control system and condenser technology, applied in steam/steam condensers, lighting and heating equipment, etc., can solve problems such as optimization and adjustment of unfavorable operation modes, unfavorable operation of operators, hidden danger of radiator freezing, etc. The effect of system network expansion, favorable operation and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

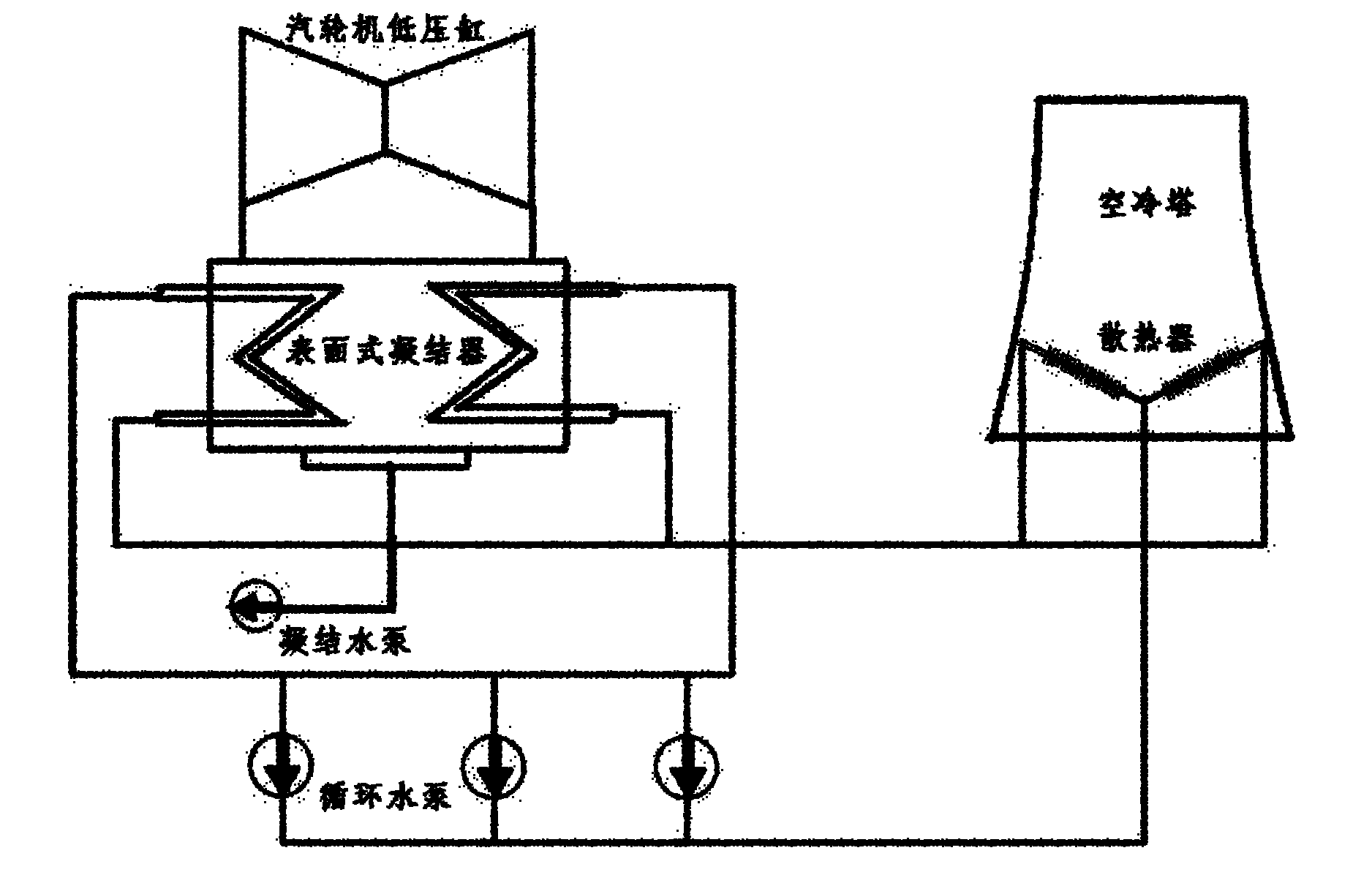

[0041] figure 1 It is a structural schematic diagram of the indirect air cooling system of the surface condenser as the basis of the indirect air cooling control system of the surface condenser of the present invention; as figure 1 As shown, the basic thermodynamic process of the indirect air cooling system of the surface condenser is: three circulating water pumps circulate the circulating cooling water from the radiator (steel cooling triangle) of the air cooling tower to the inside of the surface condenser. The exhaust steam from the low-pressure cylinder of the steam turbine enters the steam side of the condenser and is condensed into condensed water by the circulatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com