Micro-structured optical fiber for polarization apparatus

A technology of microstructured optical fiber and polarizing device, which is applied in the direction of polarized optical fiber, clad optical fiber, optical waveguide and light guide, etc. It can solve the problems of inability to realize mass production, complicated manufacturing process, and large size, and achieve mass production and manufacturing The effect of simple method and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

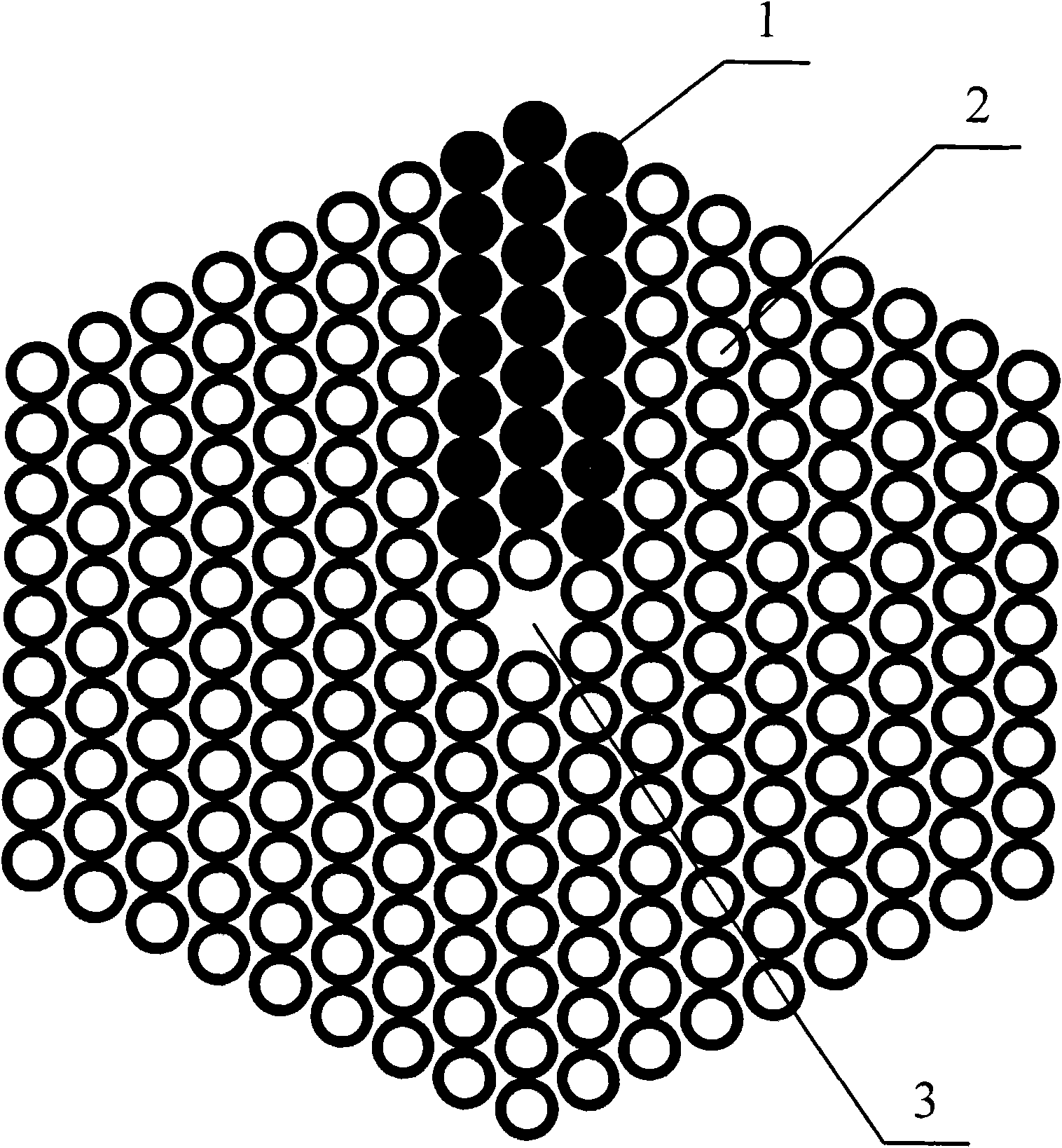

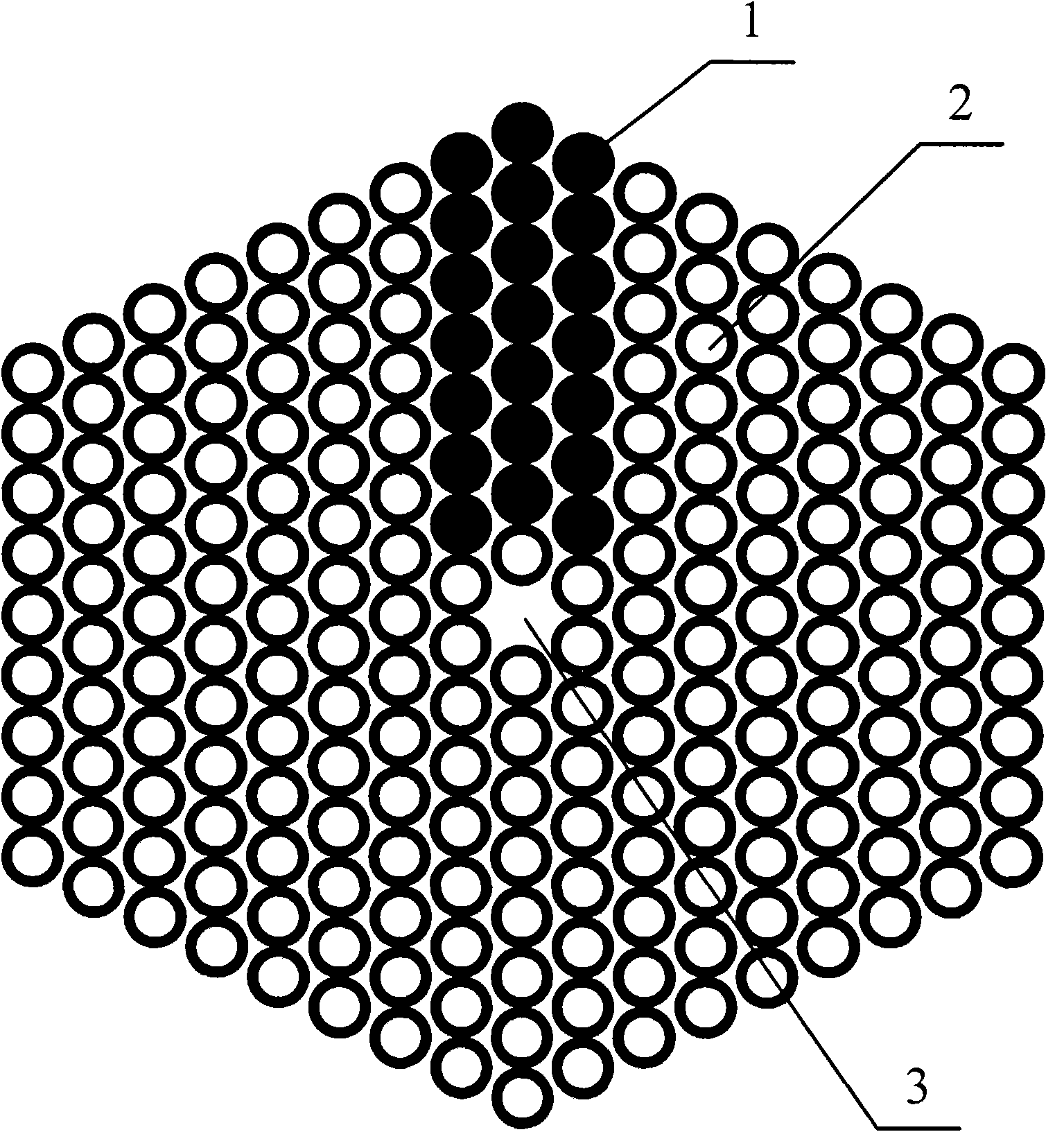

[0013] Such as figure 1 As shown, in the pretreatment stage before the microstructured optical fiber is drawn, the solid quartz rods 1 are arranged in a triangular lattice in a specific area of the preform, and the hollow quartz rods 2 are arranged in a triangular lattice in the rest of the area, forming a total of eight layers of hexagonal quartz The rods are arranged; the preform rods are then drawn into an optical fiber with a diameter of 125 μm; the specific area refers to the area except the innermost layer in the three central columns vertically above the air core 3 .

[0014] The present invention is based on the following principles:

[0015] Microstructured fiber, also known as holey fiber or photonic crystal fiber, is a new type of fiber with excellent optical properties. In its cladding, there are air holes of wavelength order that are periodically arran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com