Boron-aluminum process for high-power transistor chip

A high-power transistor and diffusion process technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of product performance impact, slow diffusion rate, small PN junction space, etc., and achieve high reliability requirements, anti-corrosion The effect of improving the burning ability and stabilizing the magnification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

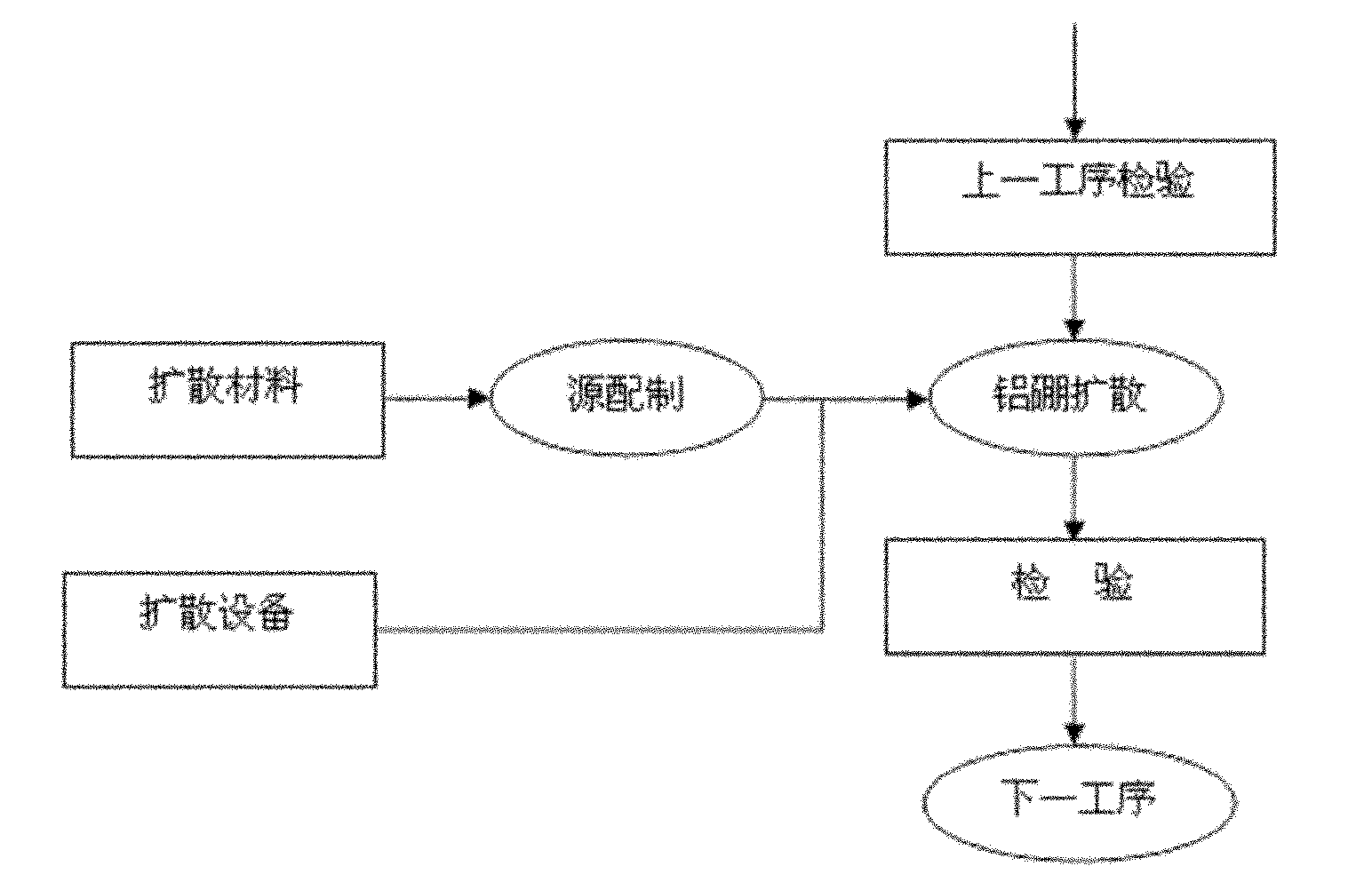

[0035] see figure 1 Shown, technique of the present invention comprises the following steps:

[0036] 1. Preparation of source solution: 40 grams of pure aluminum nitrate, 1.5 grams of diboron trioxide dissolved in 500ml of ethanol (electronic pure) and ultrasonicated for 4 hours to ensure full dissolution;

[0037] 2. Silicon wafer cleaning: Put the silicon wafer into deionized water and ultrasonically remove sand until the ionized water is clear; then put the sand-removed silicon wafer into a quartz beaker, add No. 1 standard cleaning solution (NH 4 OH / H 2 o 2 / H 2 O is mixed according to the ratio of 1:1:5 to 1:2:7), heated to boiling, and kept for 5 minutes, then removed and washed with deionized water;

[0038] 3. Drying of silicon wafers: dehydrate the cleaned silicon wafers in step 2 with absolute ethanol, and dry them in an oven at 120±3°C;

[0039] 4. Coat the surface of the silicon wafer dried in step 3 with the source solution prepared in step 1; suck the sourc...

Embodiment 2

[0041] Present embodiment technology comprises the following steps:

[0042] 1. Preparation of source solution: 40 grams of pure aluminum nitrate, 2 grams of diboron trioxide dissolved in 500ml of ethanol (electronic pure) and ultrasonicated for 4 hours to ensure full dissolution;

[0043] 2. Silicon wafer cleaning: Put the silicon wafer into deionized water to remove sand by ultrasonic until the ionized water is clear; then put the sand-removed silicon wafer into a quartz beaker, add No. 1 standard cleaning solution, heat to boiling, and keep the time 8 minutes, then remove and wash with deionized water;

[0044] 3. Drying of silicon wafers: dehydrate the cleaned silicon wafers in step 2 with absolute ethanol, and dry them in an oven at 120±3°C;

[0045] 4. Coat the surface of the silicon wafer dried in step 3 with the source solution prepared in step 1; suck the source with a dropper, and apply it evenly on the grinding surface. After the source solution is slightly dry, ap...

Embodiment 3

[0047] Present embodiment technology comprises the following steps:

[0048] 1. Preparation of source solution: 40 grams of pure aluminum nitrate, 2.5 grams of diboron trioxide dissolved in 500ml of ethanol (electronic pure) and ultrasonicated for 4 hours to ensure full dissolution;

[0049] 2. Silicon wafer cleaning: Put the silicon wafer into deionized water to remove sand by ultrasonic until the ionized water is clear; then put the sand-removed silicon wafer into a quartz beaker, add No. 1 standard cleaning solution, heat to boiling, and keep the time 10 minutes, then remove and wash with deionized water;

[0050] 3. Drying of silicon wafers: dehydrate the cleaned silicon wafers in step 2 with absolute ethanol, and dry them in an oven at 120±3°C;

[0051] 4. Coat the surface of the silicon wafer dried in step 3 with the source solution prepared in step 1; suck the source with a dropper, and apply it evenly on the grinding surface. After the source solution is slightly dry,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com