Low-speed and zero-speed rotor position observation method and device during fault-tolerant operation of synchronous motor

A technology of synchronous motor and rotor position, which is applied in the control of electromechanical transmission, motor generator control, electronic commutation motor control, etc. It can solve the problem of less sensorless technology of synchronous motor, and achieve the expansion of operating speed range and good real-time performance. , the effect of algorithm simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

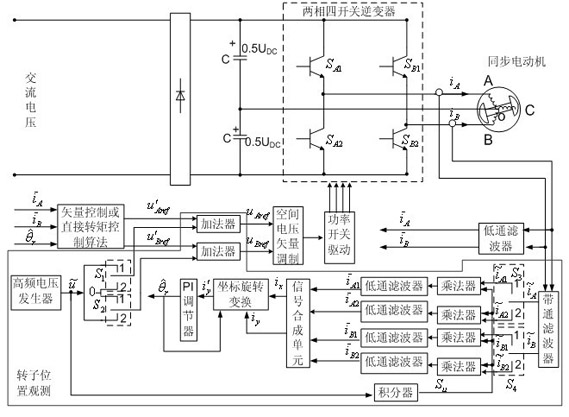

[0020] Now take the open circuit of the C-phase winding of the motor as an example, and describe it as follows.

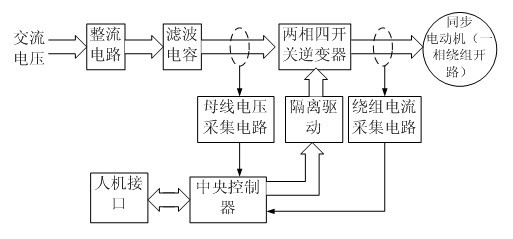

[0021] The control principle block diagram of the inventive method is as figure 1 shown. The AC voltage is rectified by a diode, and then filtered into a DC voltage by two equal-capacity capacitors C Finally, it is added to the two-phase four-switch inverter that controls the two-phase winding voltage of the synchronous motor. The midpoint O of the two-phase winding of the motor is connected to the midpoint of the two capacitors. Sampling value of two-phase winding current of synchronous motor , The fundamental component is output after being filtered by a low-pass filter , ;Vector control or direct torque control algorithm link according to the input current fundamental wave component , and rotor position angle , calculate the given initial value of the stator two-phase winding voltage , ; If there is no rotor position observation link, , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com