Flexible electrothermal drive micro-gripper and manufacturing process method

An electrothermal drive and micro-clamp technology, which is applied in the direction of manufacturing tools, metal material coating technology, and technology for producing decorative surface effects, etc., can solve the problem of affecting the operation, the asymmetry of the distribution of the metal layer and the SU-8 structural layer and other problems, to achieve the effect of low clamping temperature, novel structure and practical application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

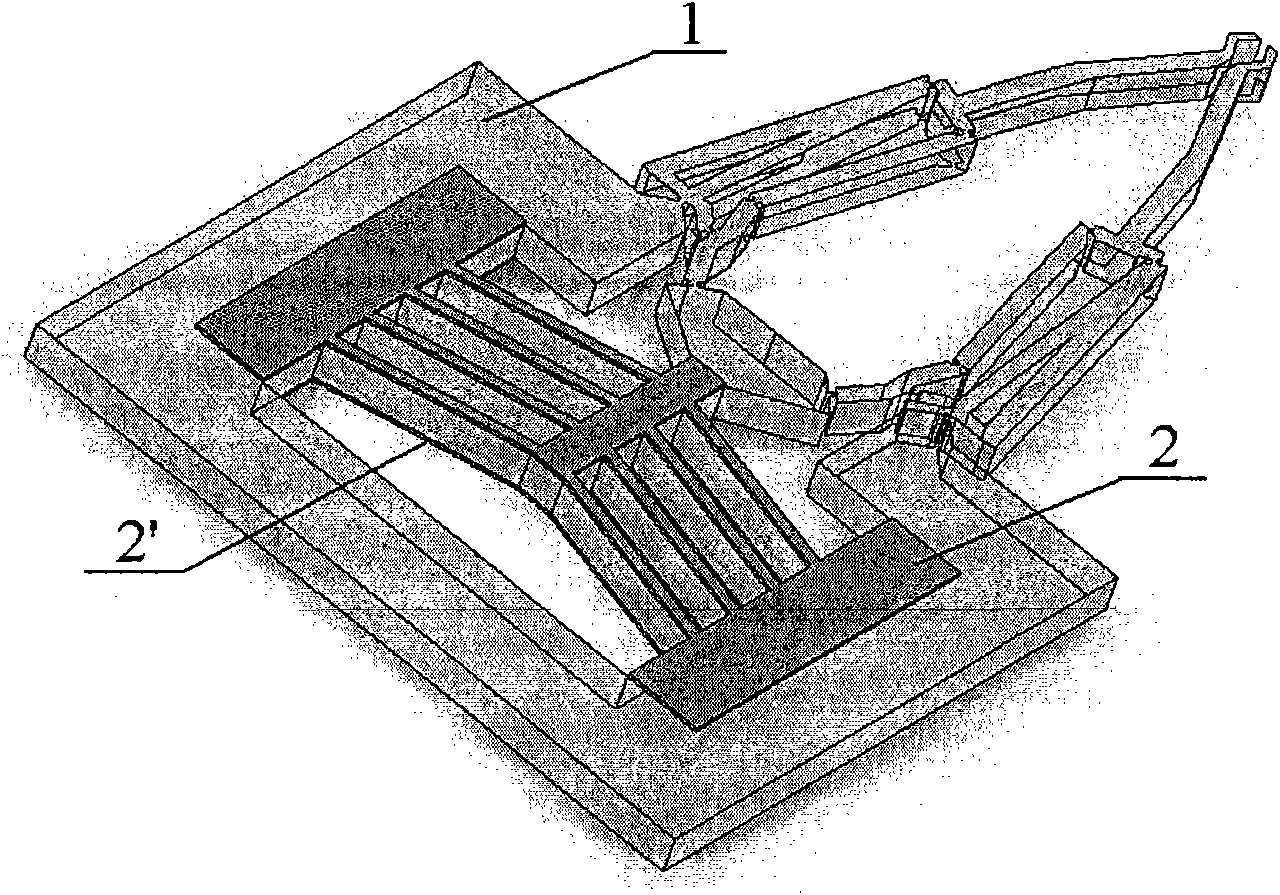

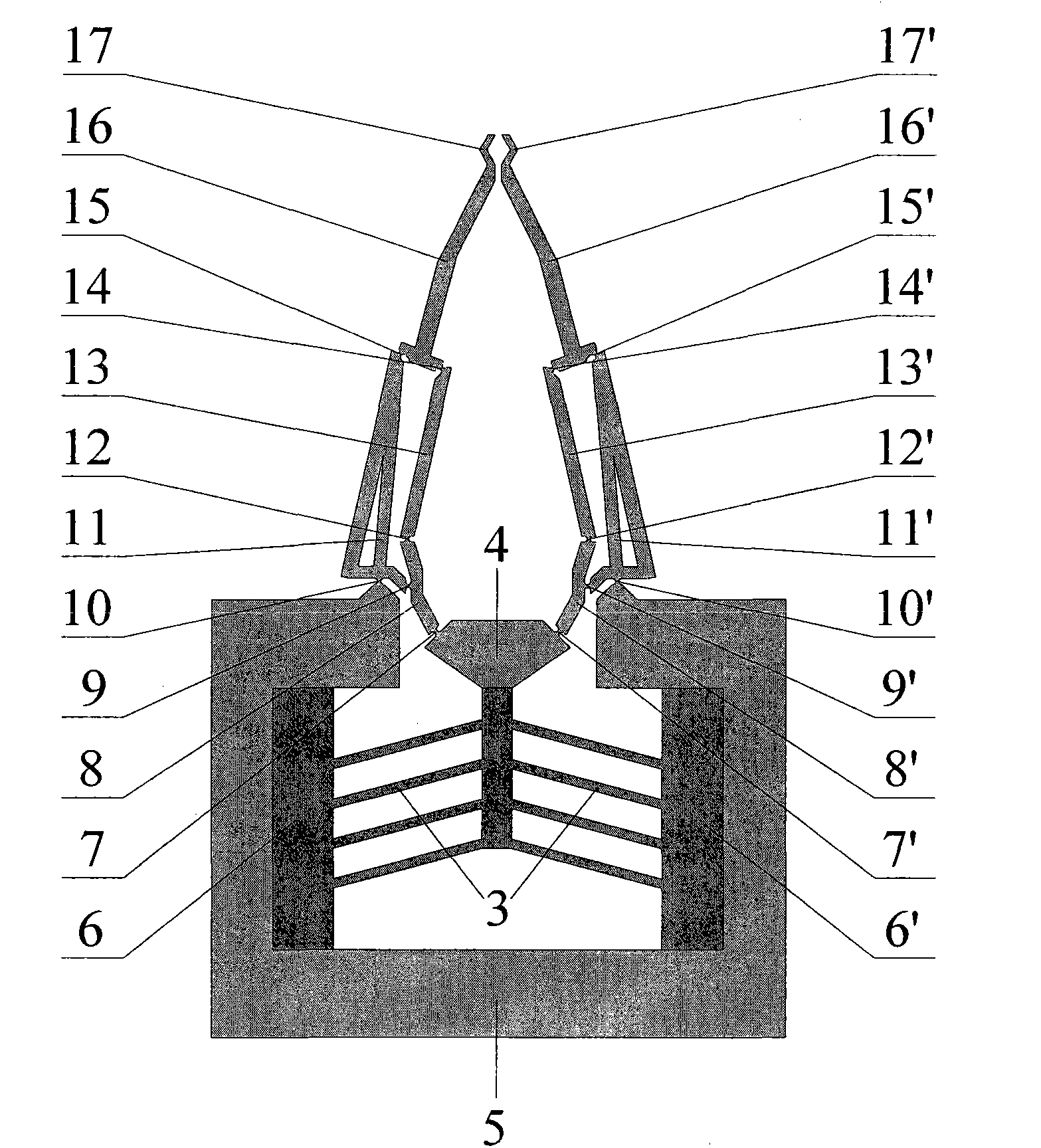

[0021] Working principle of the present invention: as attached figure 1 As shown, the micro-clamp adopts a sandwich-like three-layer symmetrical structure of upper electrode metal layer 2 - SU-8 glue structure layer 1 - lower electrode metal layer 2'. as attached figure 2 As shown, after applying a suitable voltage on the left and right electrodes 6, 6', current flows through the metal layers 2, 2' of the upper and lower electrodes, generating Joule heat, which is transferred to the Λ beam composed of 4 Λ beams. The beam array 3 makes the Λ beam expand and elongate, and promotes the driving displacement rod 4 to make it generate upward force and motion. This force and motion promote the left and right first rocking bars 8, 8' to move upwards by the left and right first flexible hinges 7,7'. The left and right fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com