Method and device for detonating and fracturing scattered objects

A fracturing and deflagration technology, which is applied in the direction of earthwork drilling, mining fluid, wellbore/well components, etc., can solve the problems of uncertain ignition position, failure to achieve fracturing effect, dispersion, etc., and achieve safe and reliable use, improve Fracturing effect, the effect of simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

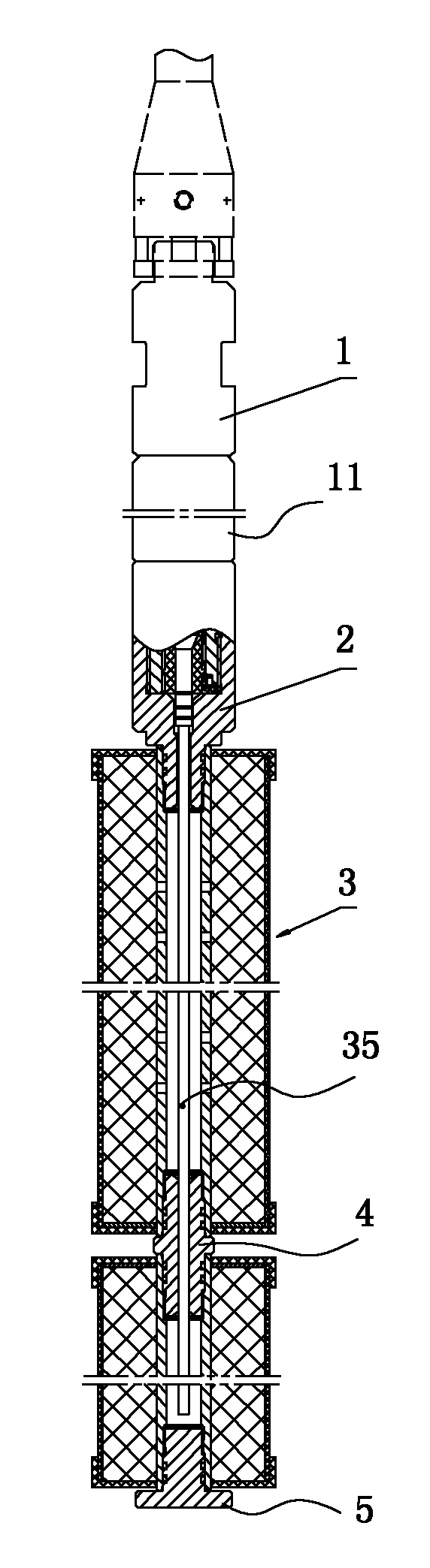

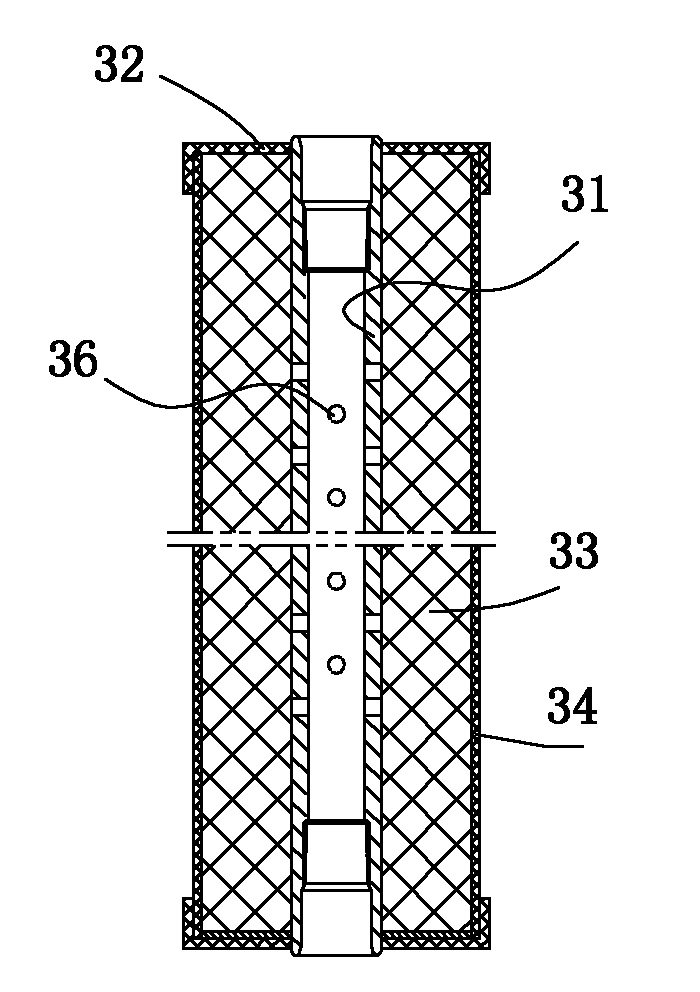

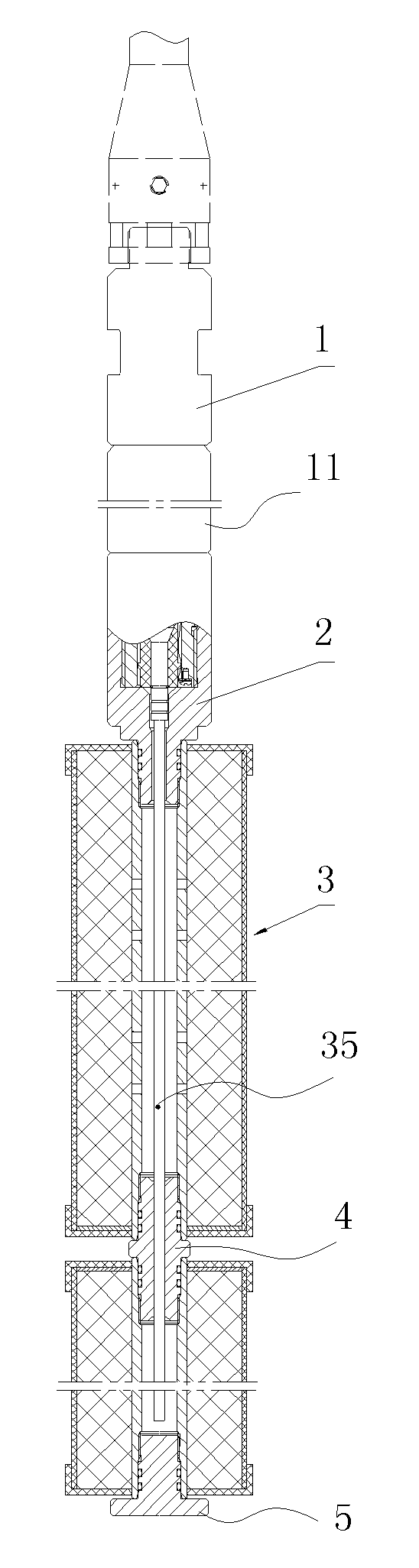

[0020] The basic structure of the fallout deflagration fracturing device is as follows: figure 1 with figure 2 shown. Center pipe 31 selects the No. 45 steel pipe that outer diameter is 25.4 millimeters (being 1 inch) for use, and its wall thickness is 3 millimeters, has two rows of through holes 36 for ignition arranged in a straight line on the pipe wall of center pipe 31, these two rows The through holes for ignition are 180 degrees to each other, and each column includes 8 through holes for ignition. The diameter of the through holes for ignition is 4 mm, and the distance between two adjacent through holes 36 for ignition is 50 mm. The pipe joint 4 and the tail plug 5 are made of carbon steel.

[0021] During operation, the cable sends the deflagration fracturing device into the fracturing layer position of the oil well, and the detonating device detonates the magnetoelectric detonator in the ignition assembly 2 through the cable, and then the detonating cord passes thr...

Embodiment 2

[0023] Steel central tube 31 outer diameter is 50.8 millimeters, and wall thickness is 5 millimeters, has on the tube wall of central tube 31 by the ignition through hole 36 of spiral distribution, and the phase angle of adjacent two ignition through holes is 45 °, the aperture of the through hole for ignition is 6 millimeters, the spacing between two adjacent through holes for ignition is 70 millimeters, and other structures are the same as in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com