Sorting system having a vertical sorter

A sorting system and sorter technology, applied in the direction of conveyor objects, transportation and packaging, can solve the problems of noise pollution, conveyor belt elongation, etc., achieve high load carrying capacity, reduce mechanical load, and avoid the effect of traction changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] refer to Figure 1 to Figure 7 Embodiments of the present invention will now be described in detail.

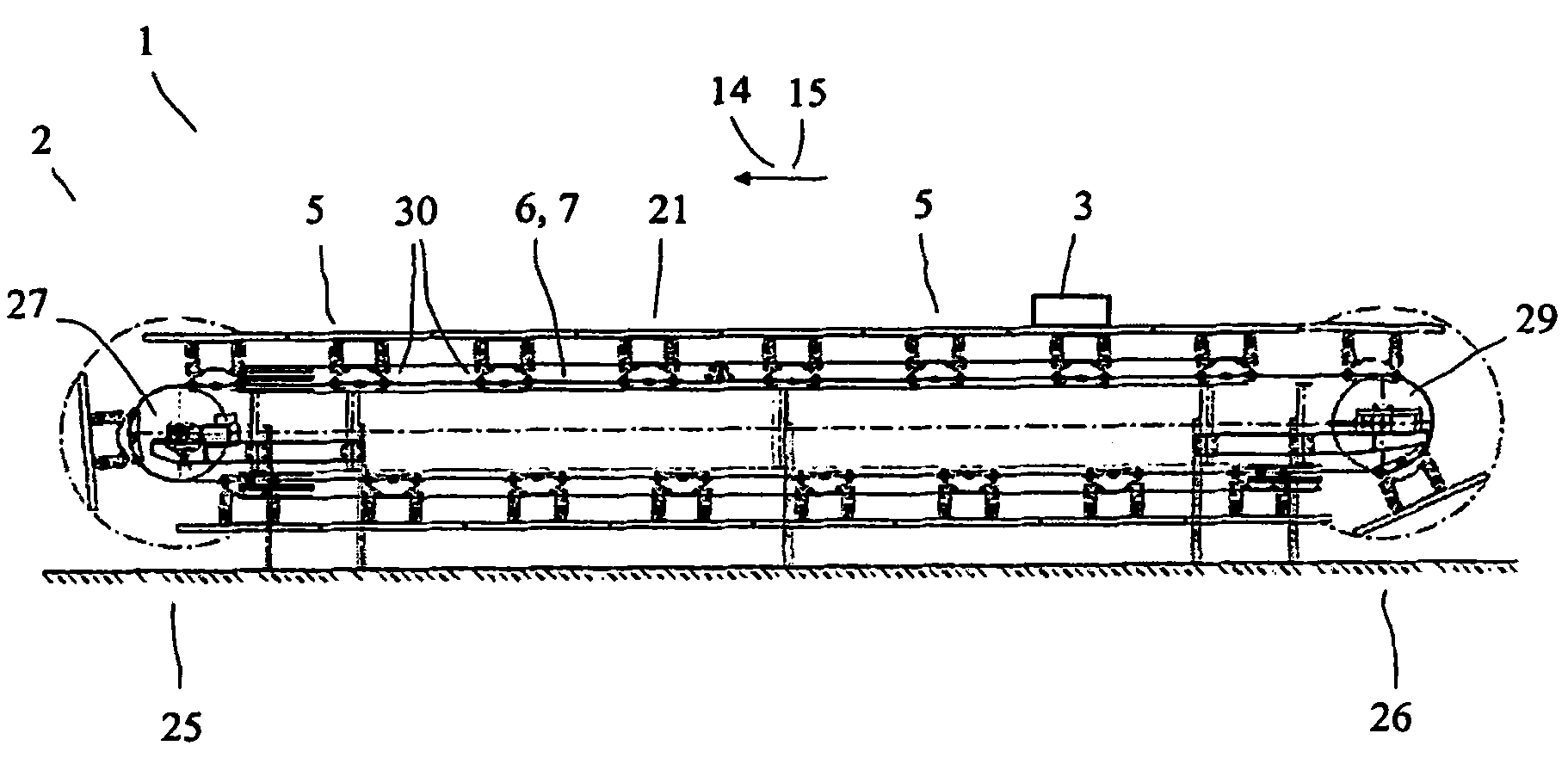

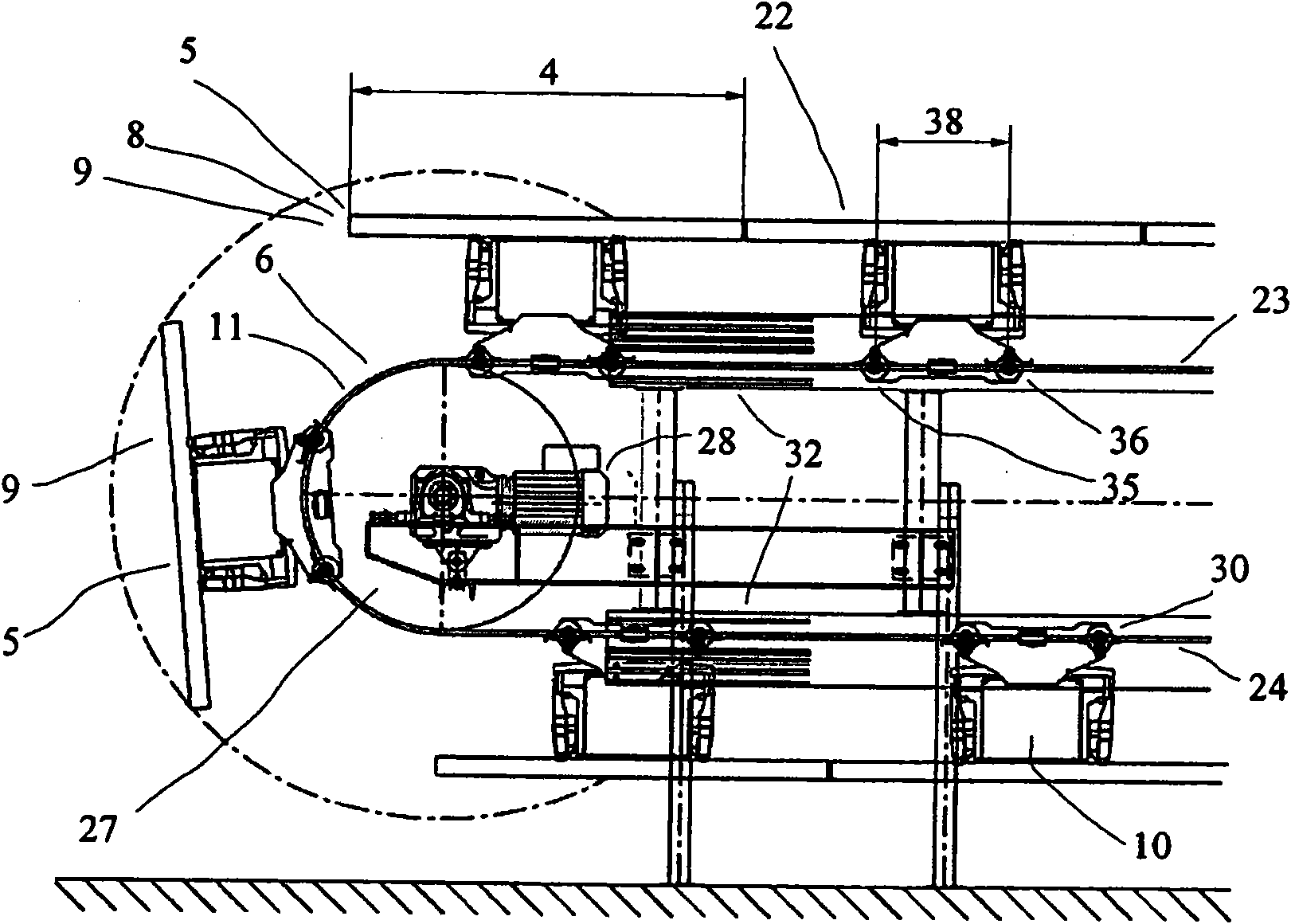

[0064] figure 1 and 2 A schematic side view of a sorting system 1 according to the invention is shown, which comprises a vertical sorter 2 which is arranged for conveying and sorting parcel goods 3 . For this purpose, the vertical sorter 2 comprises a plurality of sorting units 5 which are connected to one another along a path of movement 7 by means of a closed conveyor belt 6 and are movable along the path of movement 7 .

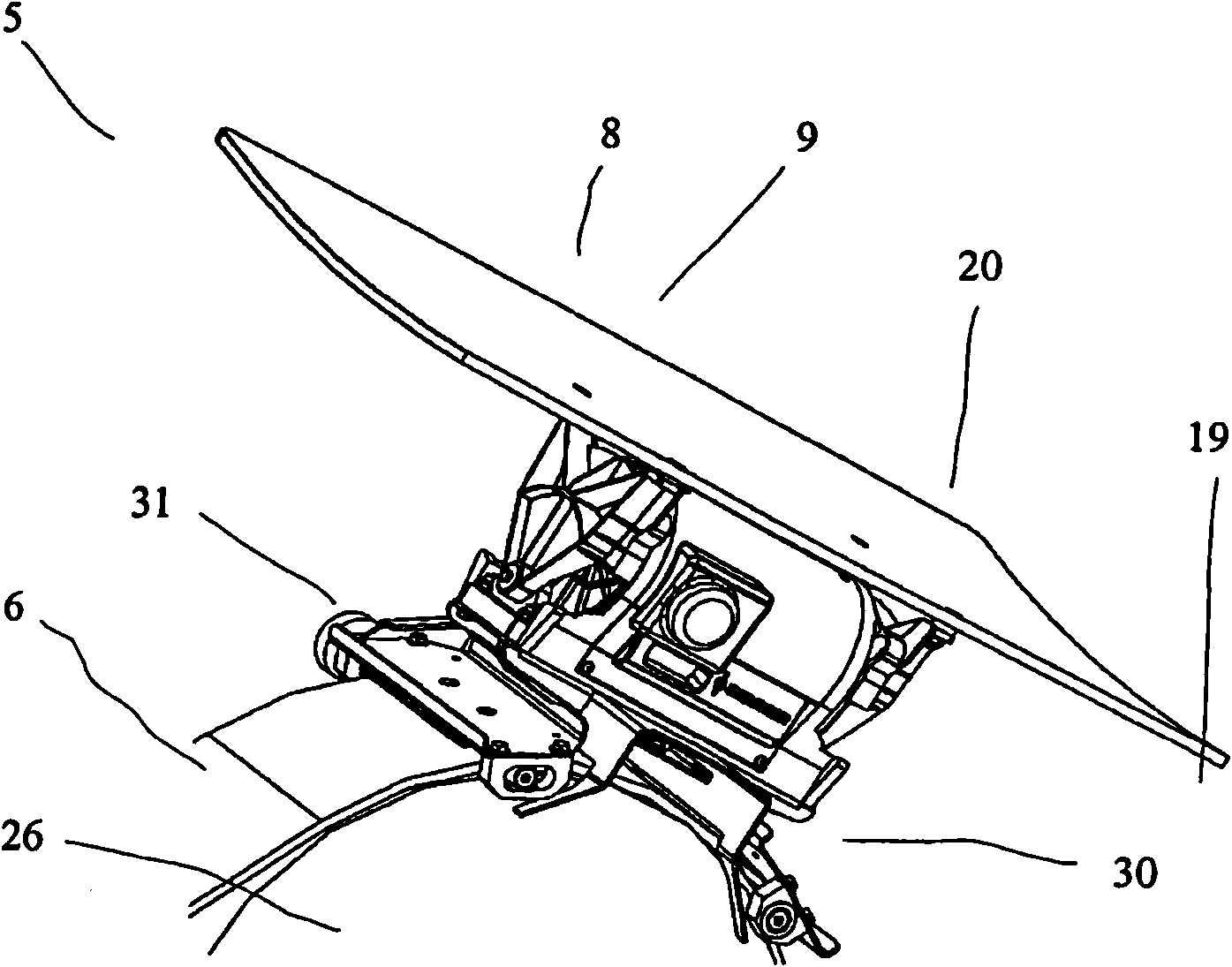

[0065] In this embodiment each sorting unit 5 comprises a carrier 30 connected to a conveyor belt 6, which is now configured to pull a carrier 11, and a package receiver 8 mounted on the carrier, in this embodiment the receiver The structure is tiltable tray 9.

[0066] The length of each sorting unit 5 is now substantially determined by the length of the tiltable tray 9 and corresponds substantially to the distance 4 between two sorting units,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com