Heating brick without burning magnesium and production method of heating brick

A production method and a heating brick technology are applied in the field of non-burning magnesia heating bricks, which can solve the problems of high density, high firing temperature, and short heating time of burned magnesia bricks, so as to save social resources, have good physical properties, and reduce heat release time. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

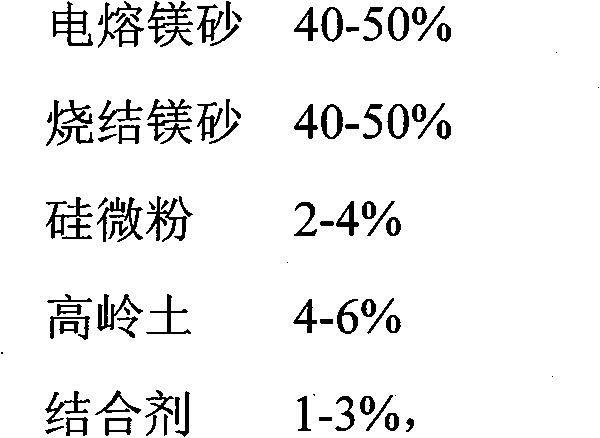

[0028] A magnesia heating brick, characterized in that: the weight percentage of each component of its constituent raw materials is:

[0029] Fused magnesia 40-50%

[0030] Sintered magnesia 40-50%

[0031] Silica powder 2-4%

[0032] Kaolin 4-6%

[0033] Binder 1-3%.

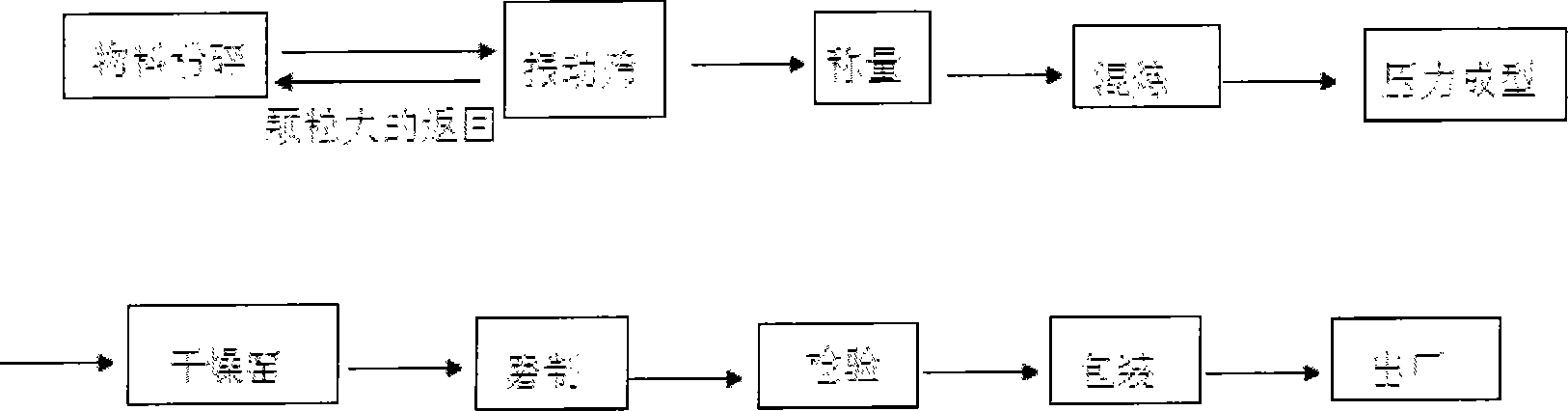

[0034] The production method of the described magnesia heating brick is characterized in that: it specifically comprises the following steps:

[0035] (1) Break the blocky material;

[0036] (2) Pass the crushed particles through a vibrating sieve, requiring the particle size to be less than 5mm, and returning large particles to continue crushing and sieving;

[0037] (3) 75-80% magnesia powder after crushing is put into the mixer as aggregate, and then the binder is put into it for premixing for 2-4 minutes;

[0038] (4) Mix the remaining magnesia powder and silicon micropowder evenly, then put the mixture into the mixture of step (3) and continue mixing for 30-40 minutes;

[0039] (4) pressure molding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com