Reinforced concrete column and preparation method thereof

A technology of reinforced concrete columns and raw materials, applied in the direction of columns, pier columns, pillars, etc., can solve problems such as difficult to use nail-fired or tool-based installation, adjust the density of the column surface, and easily generate cracks, etc., to improve the anti-vibration performance of the connection , cushion the direct impact force, offset the effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

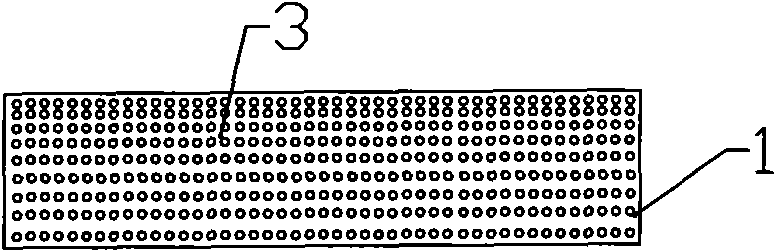

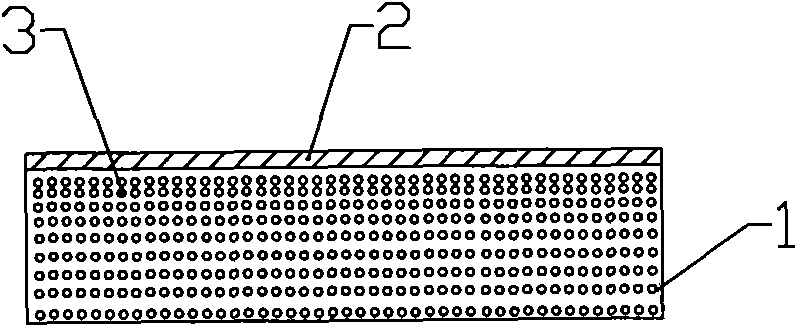

[0027] Embodiment 1: as figure 1 As shown, a reinforced concrete column includes the following raw materials in parts by weight: 38 parts of fine stone with a particle size of 5-10mm, 30 parts of medium sand, 28 parts of Portland cement, and 0.2 parts of polystyrene particles with a particle size of 3-5mm and chopped fiber 0.8 part;

[0028] The above reinforced concrete columns are prepared according to the following method:

[0029] (a) Slurry preparation process: take fine stone, medium sand, Portland cement, polyphenylene particles, chopped fibers and water according to the above proportions and mix them evenly to obtain slurry, and the consumption of water is 40% of the cement weight;

[0030] (b) Pouring process: use cold-drawn steel bars to be welded into steel bar skeletons and place them in the mold for making flat plates, then put the slurry into the molds and spread until smooth;

[0031] (c) Vibration process: the mold is placed on the vibration platform, and the...

Embodiment 2

[0034] Embodiment 2: as figure 1 As shown, a reinforced concrete column includes the following raw materials in parts by weight: 43 parts of fine stone with a particle size of 5-10mm, 32 parts of medium sand, 30 parts of Portland cement, and 0.15 parts of polystyrene particles with a particle size of 3-5mm and chopped fiber 1 part;

[0035] The above reinforced concrete columns are prepared according to the following method:

[0036] (a) Slurry preparation process: take fine stone, medium sand, Portland cement, polyphenylene particles, chopped fibers and water according to the above ratio and mix them evenly to obtain slurry, and the consumption of water is 45% of the cement weight;

[0037] (b) Pouring process: use cold-drawn steel bars to be welded into steel bar skeletons and place them in the mold for making flat plates, then put the slurry into the molds and spread until smooth;

[0038] (c) Vibration process: the mold is placed on the vibration platform, and the vibrat...

Embodiment 3

[0041] Embodiment 3: as figure 1 As shown, a reinforced concrete column includes the following raw materials in parts by weight: 41 parts of fine stone with a particle size of 5-10mm, 29 parts of medium sand, 29 parts of Portland cement, and 0.17 parts of polystyrene particles with a particle size of 3-5mm and chopped fiber 0.9 parts;

[0042] The above reinforced concrete columns are prepared according to the following method:

[0043] (a) Slurry preparation process: take fine stone, medium sand, Portland cement, polyphenylene particles, chopped fibers and water according to the above ratio and mix them evenly to obtain slurry, the amount of water is 43% of the cement weight;

[0044] (b) Pouring process: use cold-drawn steel bars to be welded into steel bar skeletons and place them in the mold for making flat plates, then put the slurry into the molds and spread until smooth;

[0045] (c) Vibration process: the mold is placed on the vibration platform, and the vibration ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com