Lithium battery compound electrode active material and preparation method thereof

A technology of electrode active materials and active materials, which is applied in the field of lithium battery composite electrode active materials and its preparation, can solve the problems of affecting the original characteristics of core materials and not easy to obtain active materials, so as to improve the conductivity and discharge power, The preparation method is simple and the effect of prolonging the cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

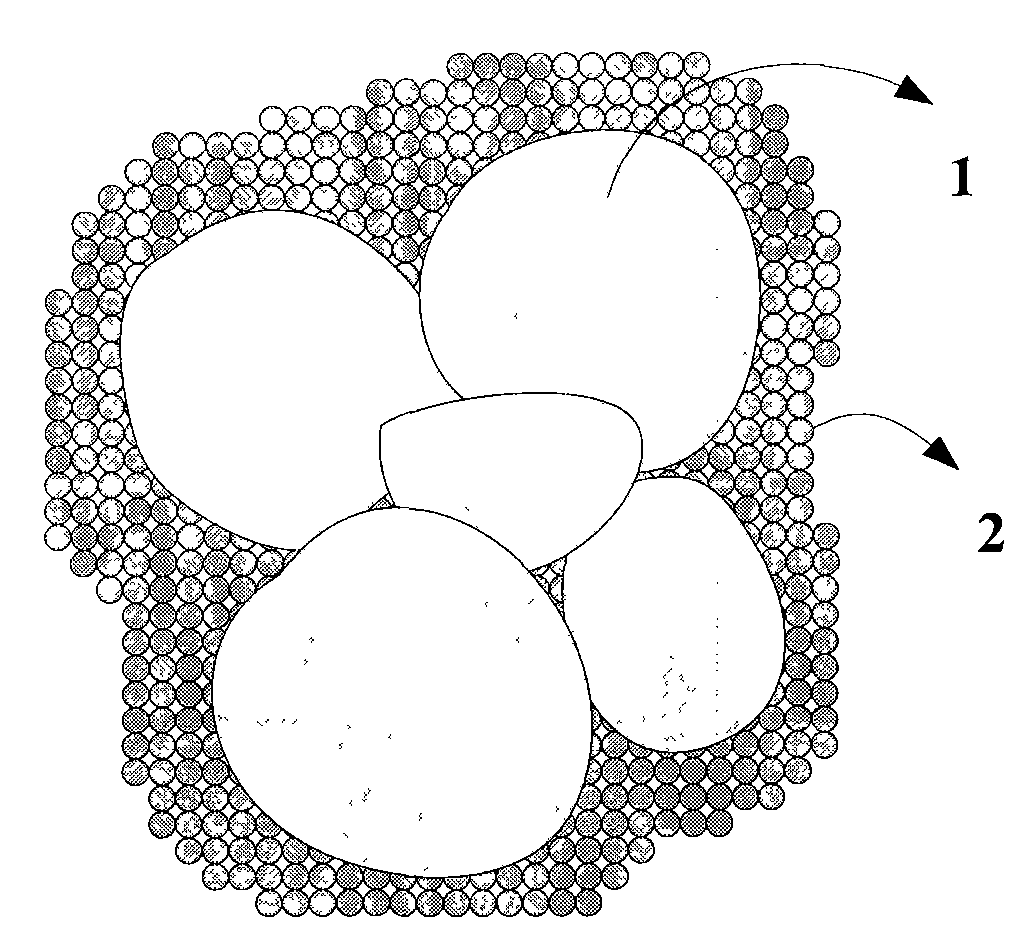

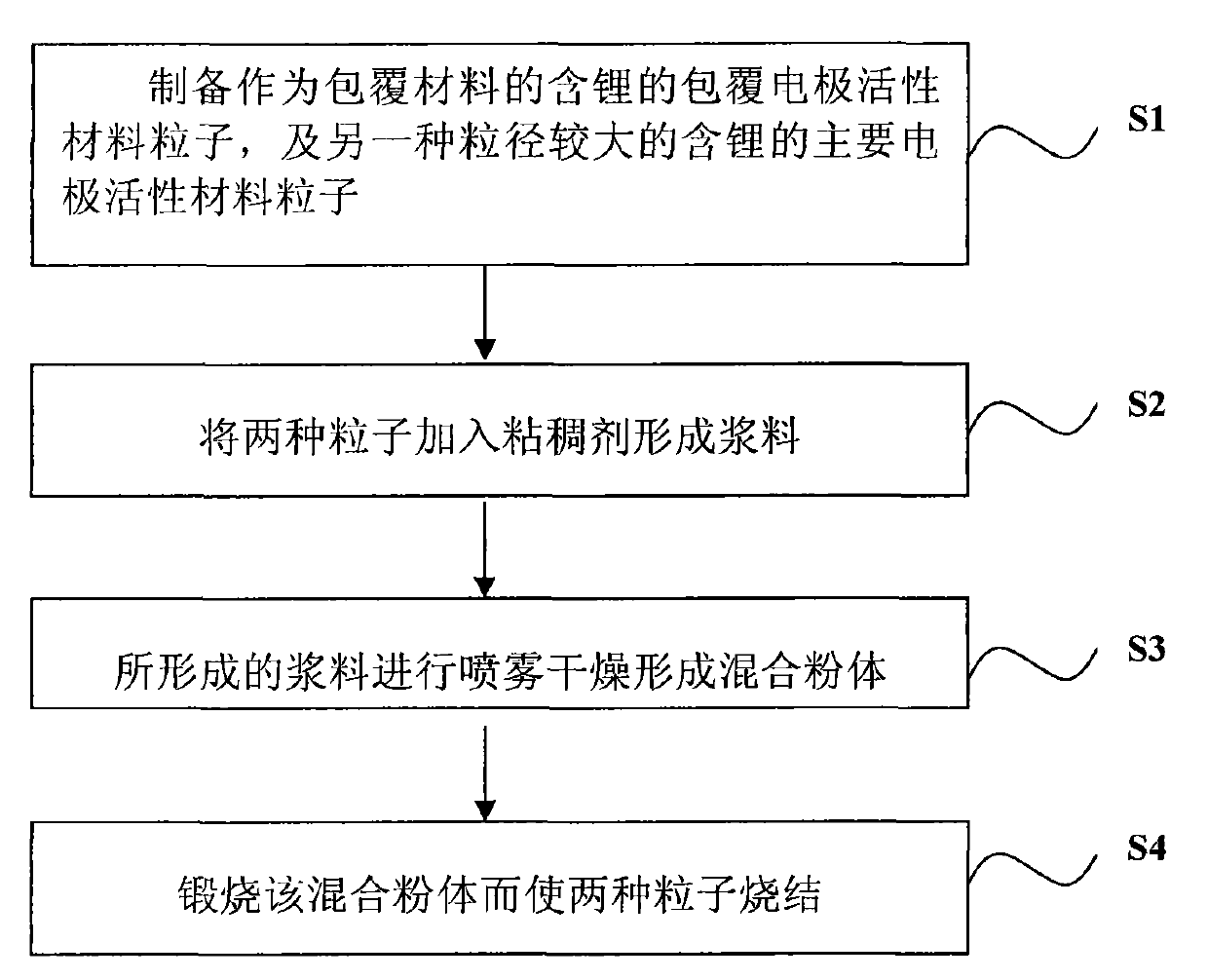

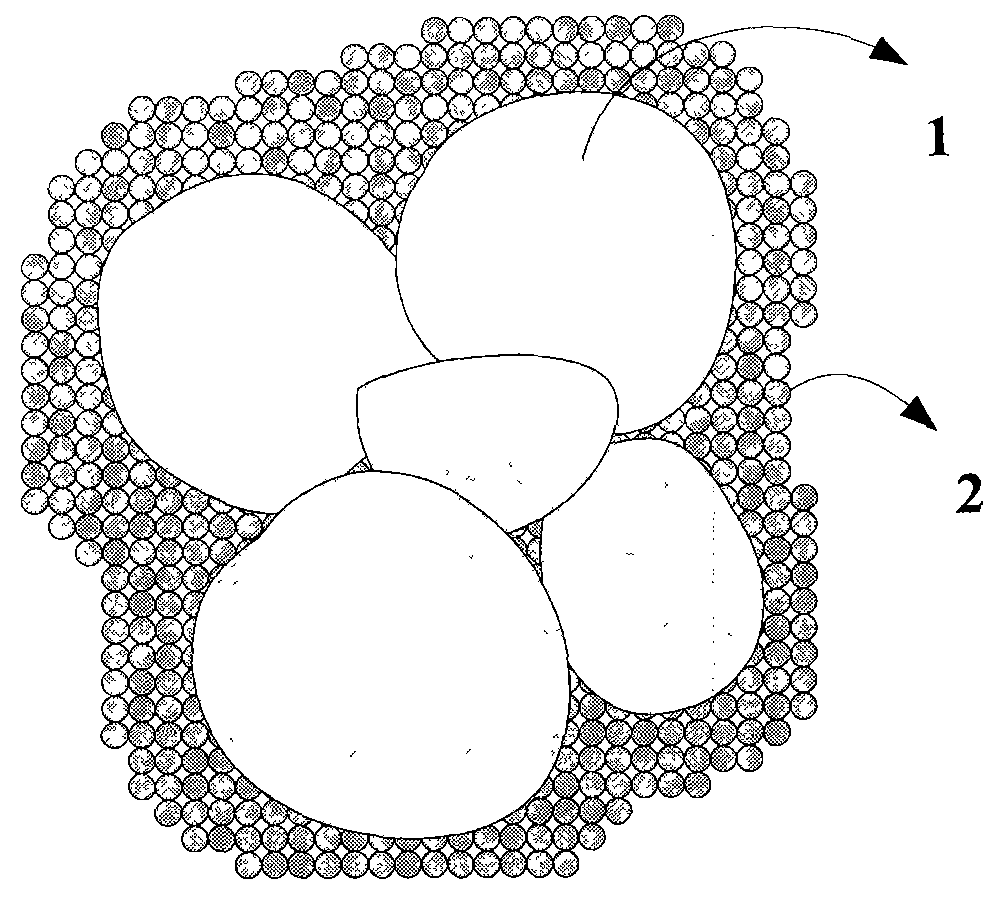

[0033] Such as figure 2 As shown, the preparation method of the lithium battery composite electrode active material provided by the present invention includes: preparing a lithium-containing fine electrode active material particle 1 as a coating layer, and another lithium-containing fine electrode active material particle 1 as the main electrode active material. Larger particle size 2 (step S1);

[0034] Next, add the above two kinds of particles into a viscous agent to form a slurry (step S2);

[0035] Again, the slurry formed in step S2 is spray-dried to form a mixed powder (step S3);

[0036] Finally, it is calcined for a short time to make it sintered (step S4).

Embodiment 1

[0037] Embodiment 1: in LiNi 0.75 co 0.2 Mg 0.05 o 2 Surface coated LiCoO 2

[0038] First provide LiCoO with a particle size of 50-100nm 2 As the coated electrode active material 2, and LiNi with a particle size of 1-10 μm 0.75 co 0.2 Mg 0.05 o 2 As the main electrode active material 1. The weight ratio of the coated electrode active material 2 to the main electrode active material 1 is maintained between 1:1 and 1:10, and a viscous agent is added, and the viscous agent is preferably carboxymethyl cellulose (Carboxymethyl Cellulose , CMC), stir it evenly to form a slurry, and then use a spray dryer to dry the slurry into a mixed powder with a particle size of 5-20 μm, and then put the powder into a high-temperature furnace at a temperature of 500 ~ Calcining at 1000°C for 0.5-5 hours and then cooling naturally.

Embodiment 2

[0039] Embodiment 2: in LiMn 2 o 4 Surface coated LiCoO 2

[0040] First provide LiCoO with a particle size of 50-100nm 2As the coated electrode active material 2, and LiMn with a particle size of 1-10 μm 2 o 4 As the main electrode active material 1. The weight ratio of the coated electrode active material 2 to the main electrode active material 1 is maintained between 1:1 and 1:10, and a viscous agent is added, and the viscous agent is preferably carboxymethylcellulose (CarboxymethylCellulose, CMC), stir it evenly to form a slurry, and then use a spray dryer to dry the slurry into a mixed powder with a particle size of 5-20 μm, and then put the powder into a high-temperature furnace and calcinate at 800 ° C for 1 Allow to cool naturally after an hour.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com