Kudzuvine root fine dried noodles and production method thereof

A technology of Pueraria vermicelli and its production method, which is applied in the fields of application, food preparation, food science, etc., can solve the problems of lack of health care function of noodles, and achieve the effect of mild production conditions and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

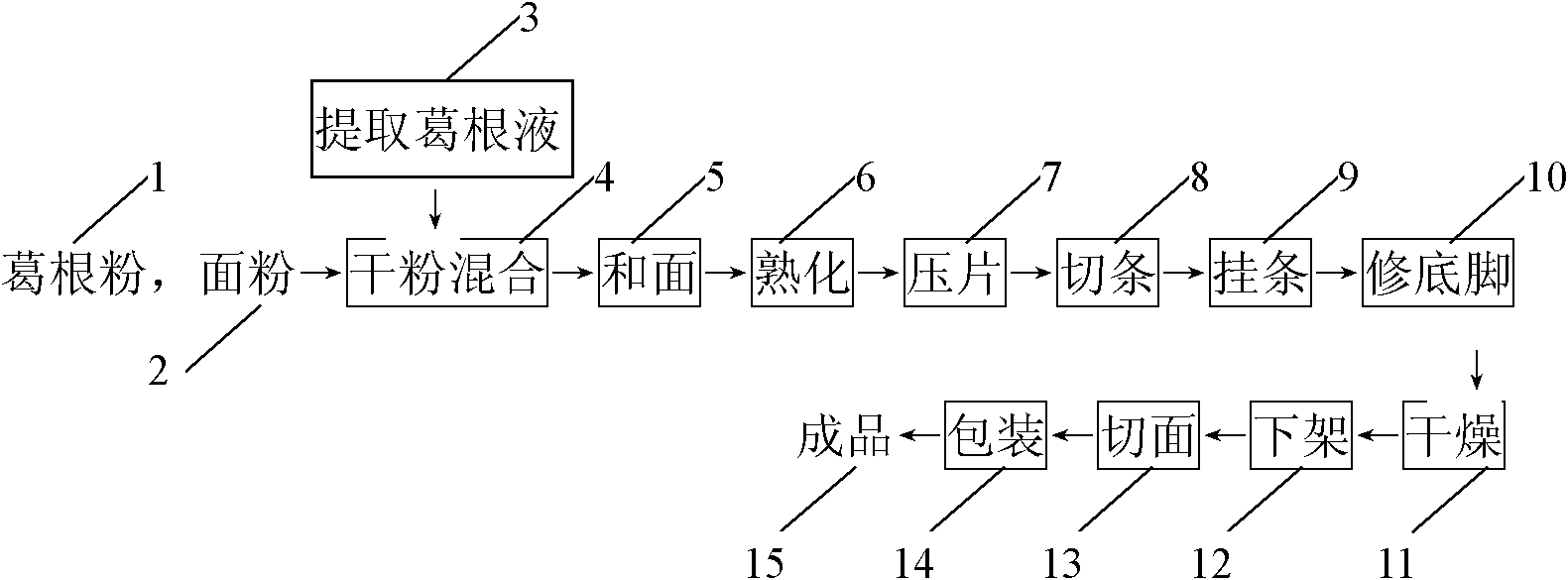

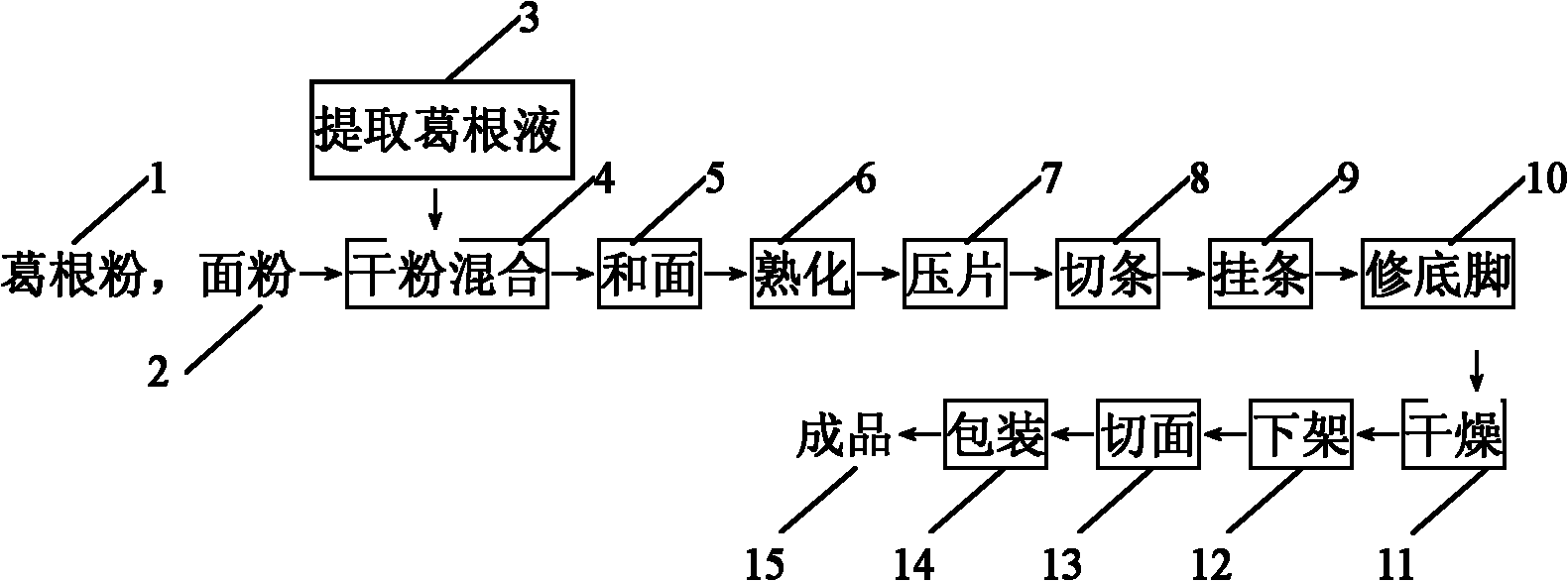

Method used

Image

Examples

Embodiment 1

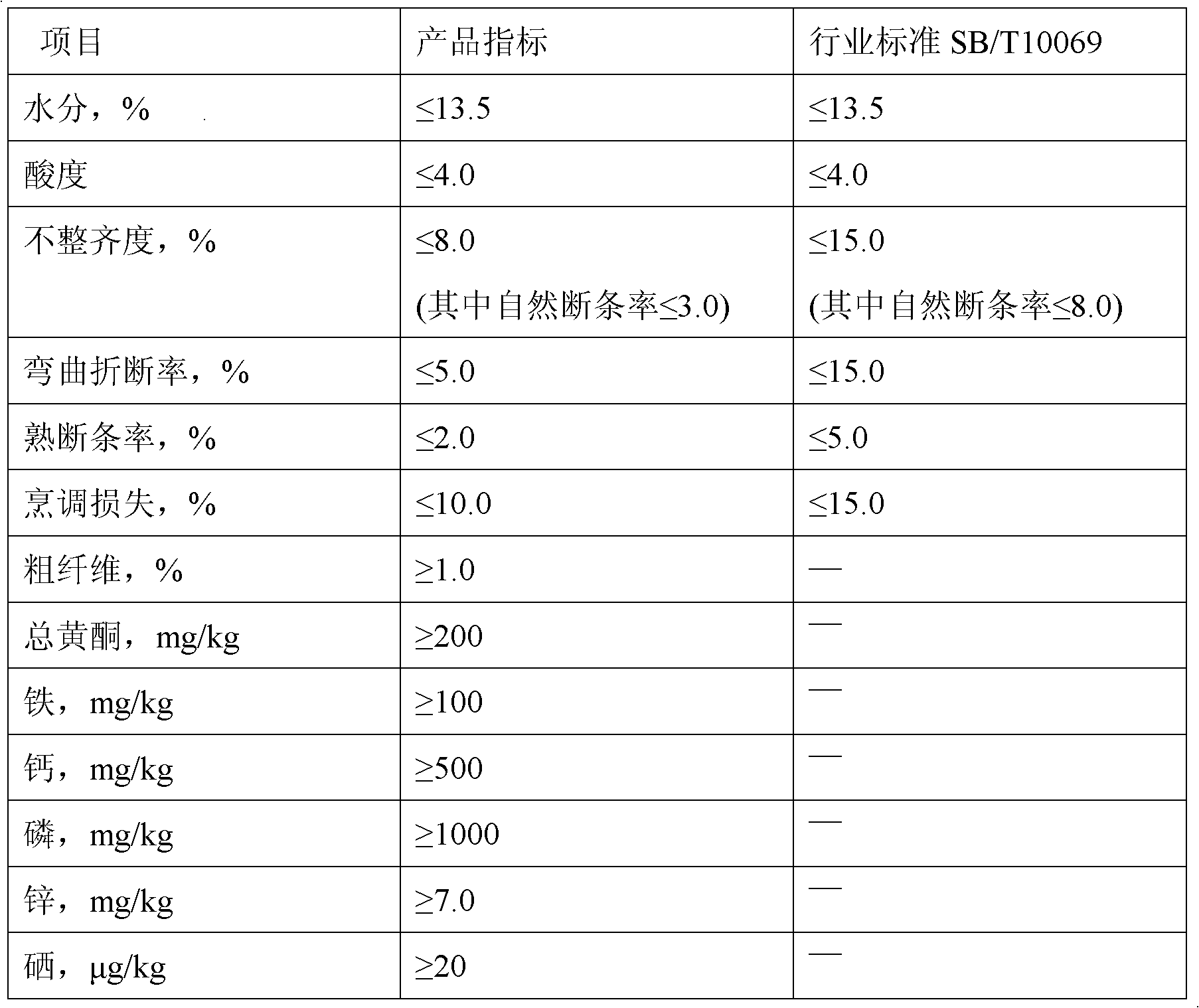

[0057]Weigh 55 kg of fresh kudzu root, add 100 kg of water, stir and heat in a steam jacketed pot, boil the water, keep warm and extract for 1.5 h, filter and remove the filter residue to obtain kudzu root liquid. Weigh 400kg special gluten refined flour and 120kg kudzu root powder, and fully stir them evenly in the dough mixer. The above-mentioned kudzu root liquid of 90kg is added in the noodle mixer, under the rotating speed of 70r / min, stir rapidly 12min. Move the mixed dough into a maturing machine, and stir for 8 minutes at a rotating speed of 30r / min to ripen the dough. The matured dough is successively rolled by 11 pairs of stainless steel rollers rotating in opposite directions at a constant speed, and the rolling ratio of each rolling is not more than 3:1 to obtain a noodle strip with a thickness of 1.00 mm. The noodle strips were cut longitudinally into circular wet noodles with a diameter of 1.0 mm with a dragon beard knife, and simultaneously cut into a length of...

Embodiment 2

[0059] Weigh 30 kg of fresh kudzu root, add 100 kg of water, stir and heat in a steam jacketed pot, boil the water, keep warm and extract for 1 hour, filter and remove the filter residue to obtain kudzu root liquid. Weigh 400kg of special gluten refined flour and 80kg of kudzu powder, and fully stir them evenly in the dough mixer. The above-mentioned kudzu root liquid of 80kg is added in the dough mixer, under the rotating speed of 60r / min, stir rapidly 10min. Move the mixed dough into the ripening machine, and stir for 6 minutes at a rotating speed of 25r / min to ripen the dough. The mature dough is successively rolled by 9 pairs of stainless steel rollers rotating in opposite directions at a constant speed, and the rolling ratio of each rolling is not more than 3:1 to obtain a noodle strip with a thickness of 0.75mm. Use a square knife to cut the noodle strip lengthwise into square wet noodles with a width of 1.2 mm, and simultaneously cut it into a length of 2000 mm with a ...

Embodiment 3

[0061] Weigh 80 kg of fresh kudzu root, add 100 kg of water, stir and heat in a steam jacketed pot, boil the water, keep warm and extract for 2 hours, filter and remove the filter residue to obtain kudzu root liquid. Weigh 400kg special gluten refined flour and 160kg kudzu root powder, and fully stir them evenly in the dough mixer. The above-mentioned kudzu root liquid of 100kg is added in the noodle mixer, under the rotating speed of 80r / min, stir rapidly 15min. Move the mixed dough into a maturing machine, and stir for 10 minutes at a rotating speed of 40r / min to ripen the dough. The matured dough is successively rolled by 13 pairs of stainless steel rollers rotating in opposite directions at a constant speed, and the rolling ratio of each rolling is not more than 3:1 to obtain a noodle strip with a thickness of 1.5 mm. The noodle strips were longitudinally cut into elliptical wet noodles with a width of 2.0 mm with an oval knife, and simultaneously cut into a length of 300...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com