Fixed type composite jet extinguishing device

A fire extinguishing device, fixed technology, applied in the field of fixed compound jet fire extinguishing device, can solve the problems of unable to meet the needs of fire extinguishing, backwardness, high risk, etc., and achieve the effects of performance compatibility, long spraying distance, and fast natural degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

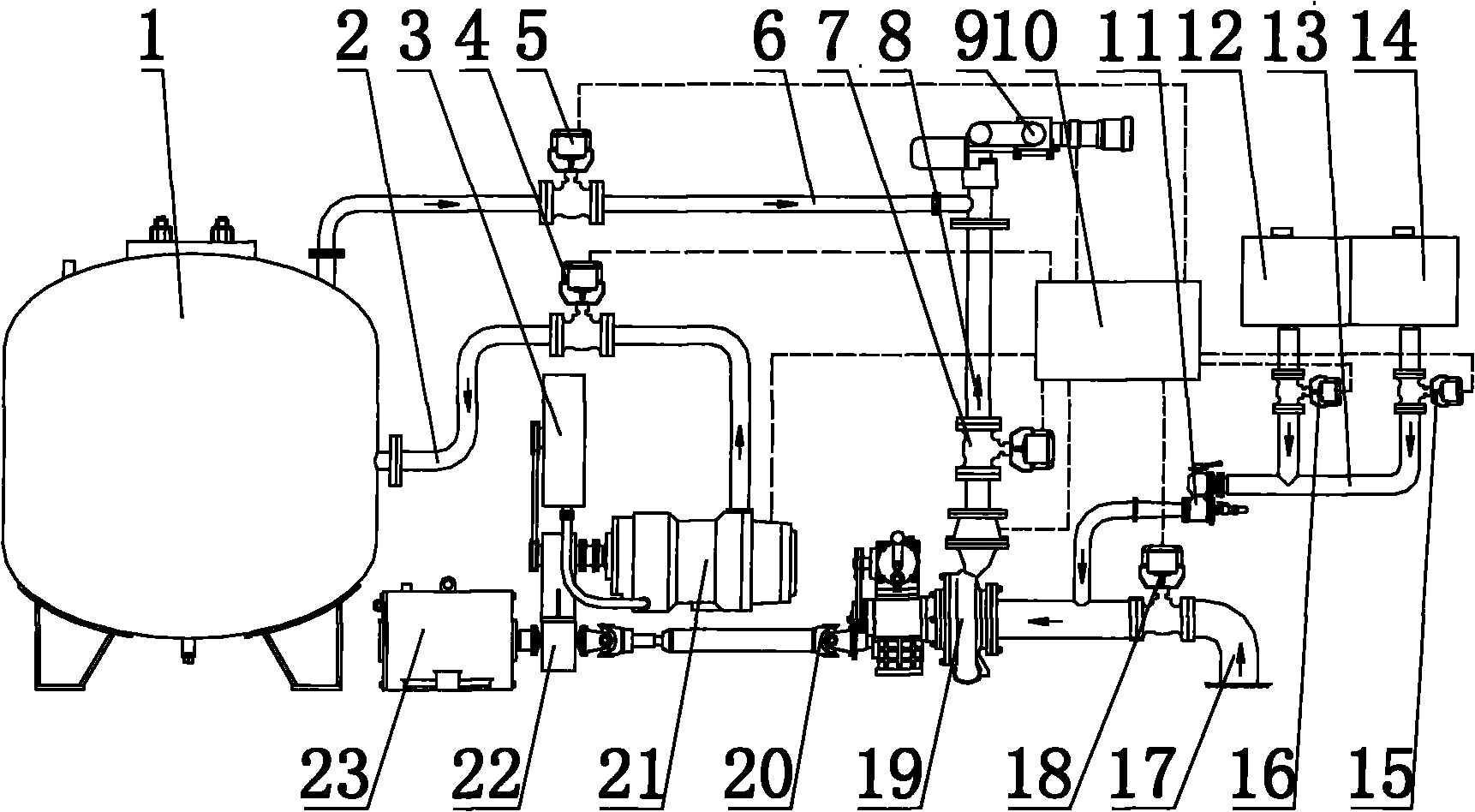

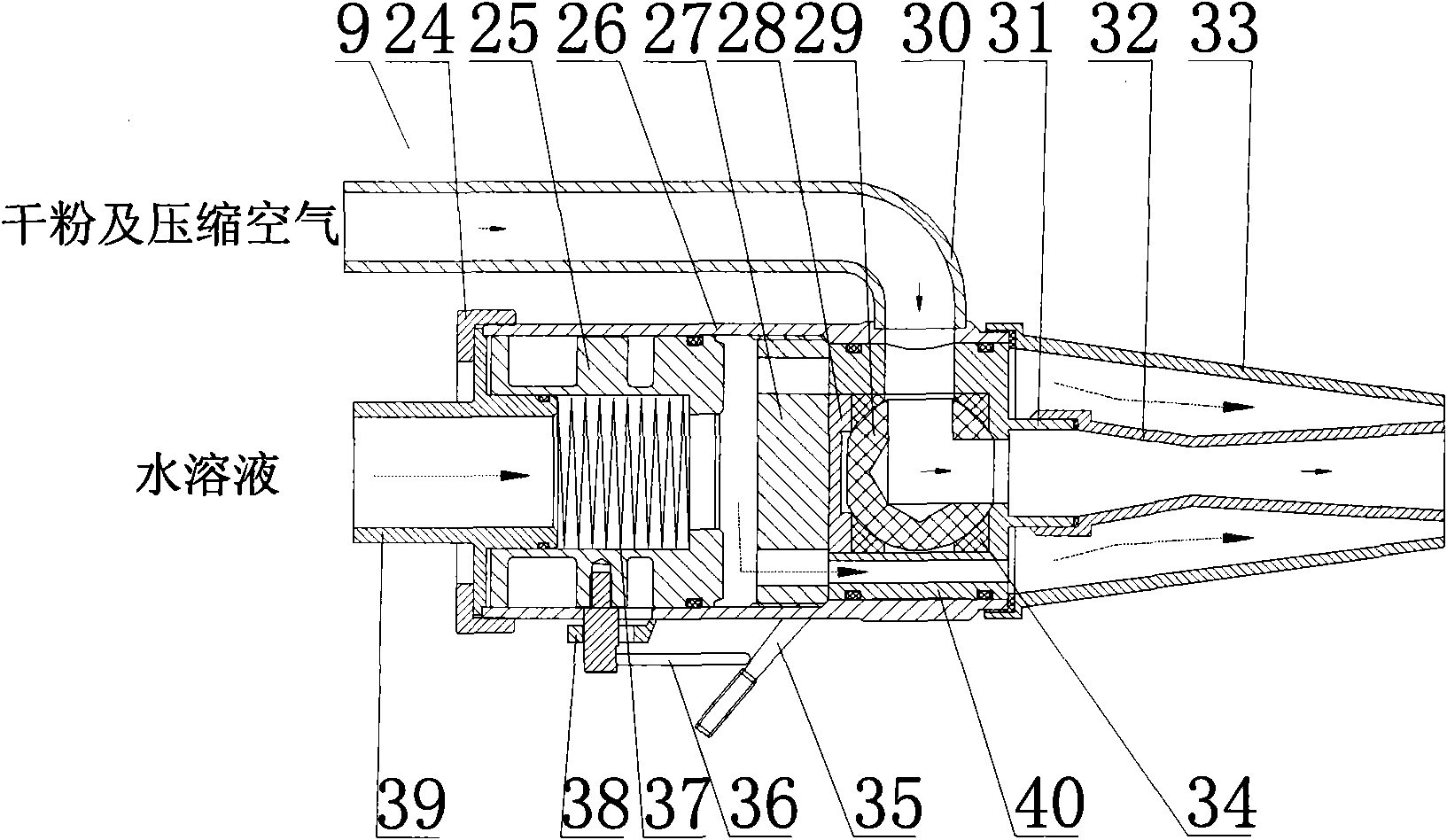

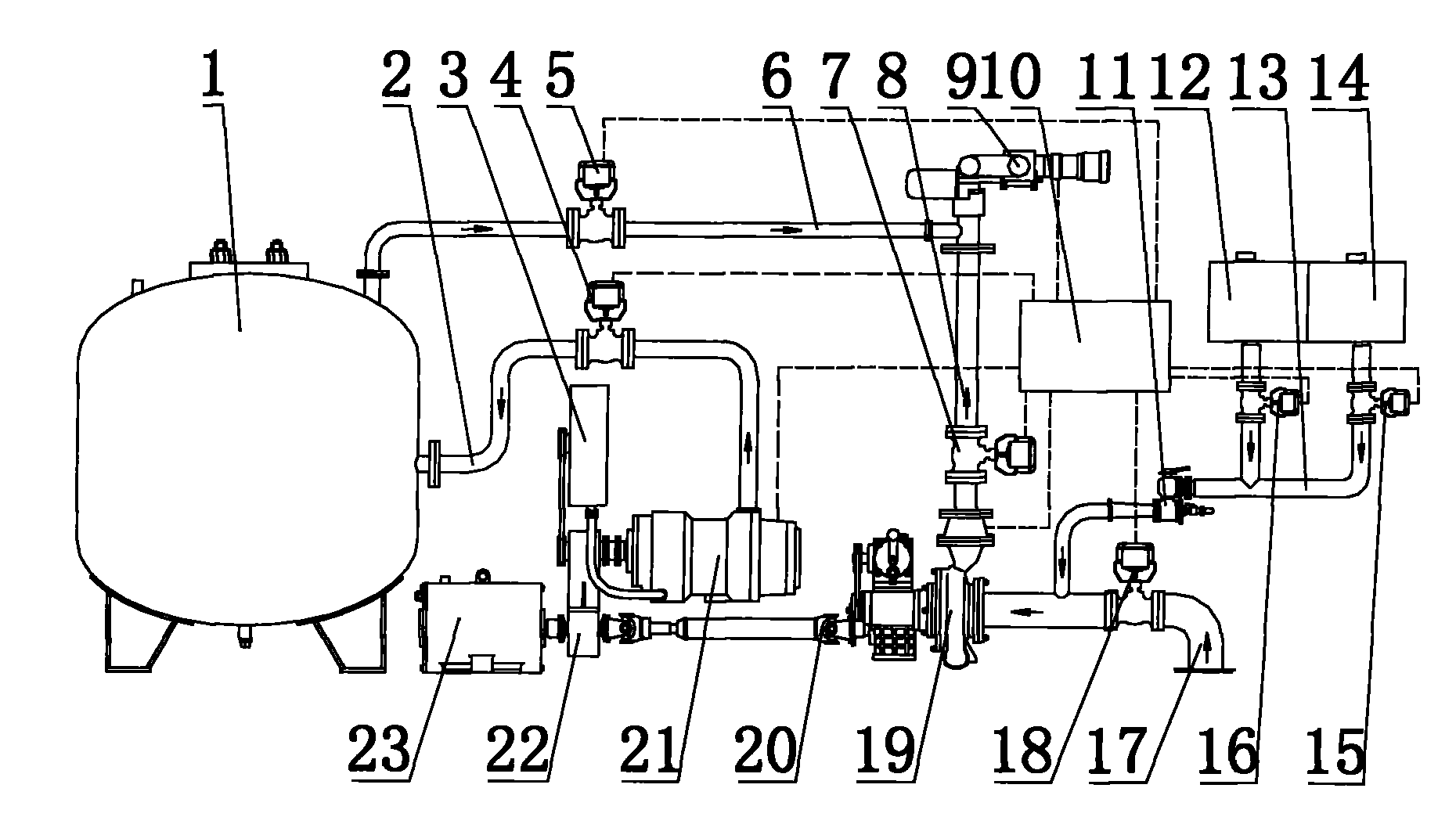

[0016] combine figure 1 The fixed composite jet fire extinguishing device of the present invention has completely different fire extinguishing methods and fire extinguishing concepts from traditional fire extinguishing methods, cancels the currently commonly used nitrogen high pressure cylinder group as the power source of dry powder, and replaces it with a large flow of sliding vane air compression The high-pressure nitrogen is replaced by low-pressure air, and the compound jet method is used instead of the single fire extinguishing agent jet method in the past. F500) fire extinguishing agent, ultra-fine dry powder and other fire extinguishing agents are sprayed out at the same time, giving full play to the advantages of various fire extinguishing agents to achieve fast, instant and high efficiency, thus greatly improving the fire extinguishing efficiency. The present invention uses DC pressure water as a carrier, and is provided with an ultra-fine dry powder tank 1, a compre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com