Double-electric-arc spraying device

A spraying device and double-arc technology, which is applied in the field of double-arc spraying device, can solve problems such as insufficient deformation of molten particles, loss of cohesion between substrate and coating, insufficient temperature and kinetic energy, etc., and achieve energy utilization. High, conducive to workpiece forming, fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

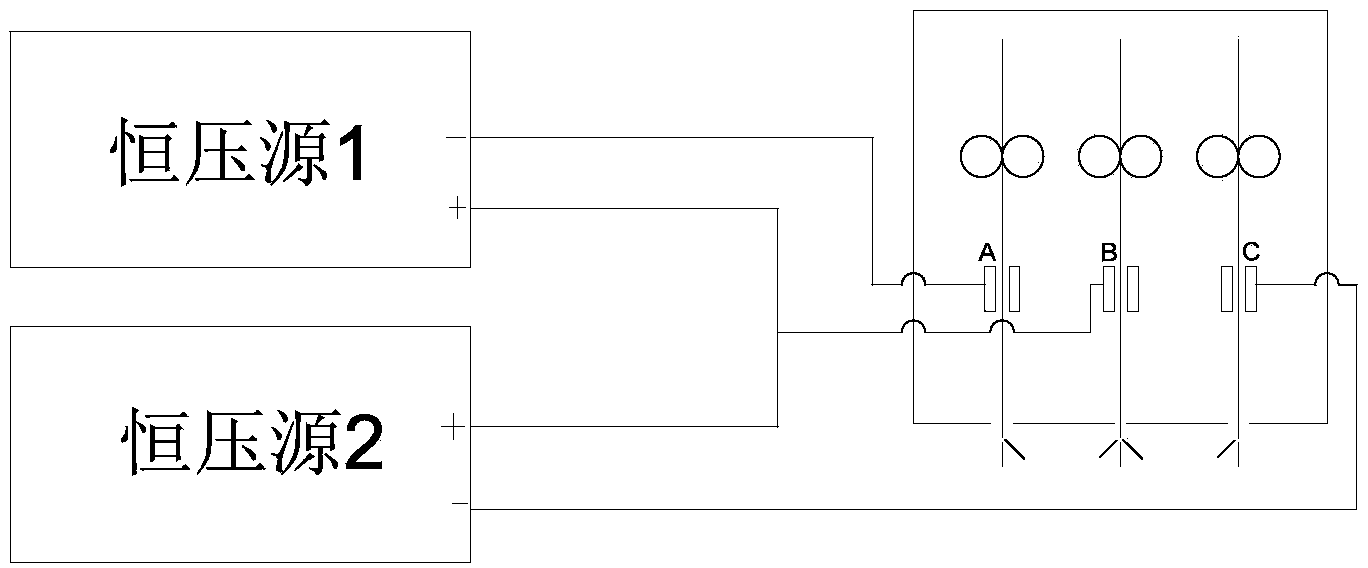

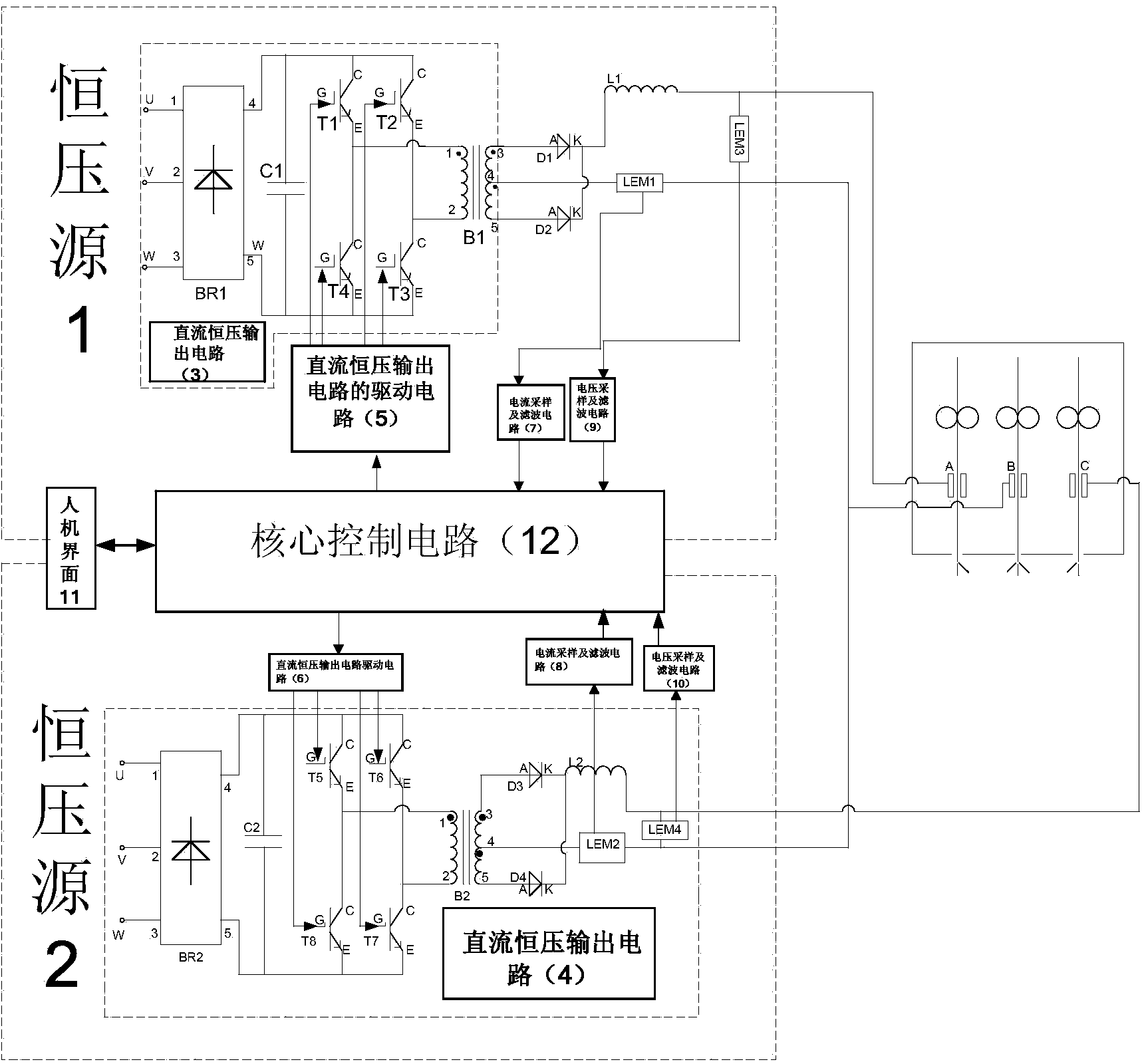

[0036] Such as image 3 As shown, the first constant voltage source circuit 1 in Embodiment 1 of the present invention includes: a DC constant voltage output circuit 3 , a drive circuit 5 for the DC constant voltage output circuit, a current sampling and filtering circuit 7 , and a voltage sampling and filtering circuit 9 . The second constant voltage source circuit 2 includes: a DC constant voltage output circuit 4 , a drive circuit 6 for the DC constant voltage output circuit, a current sampling and filtering circuit 8 , and a voltage sampling and filtering circuit 10 . The drive circuits 5 and 6 of the DC constant voltage output circuit are composed of IGBT dedicated drive chips M57962, the main control circuit 12 is composed of a single-chip microcomputer PIC30f2020, and the man-machine interface 11 is composed of conventional display circuits such as LED or LCD, and circuits such as keyboards and encoders.

[0037] Figure 5 It is the schematic diagram of the main circui...

Embodiment approach 2

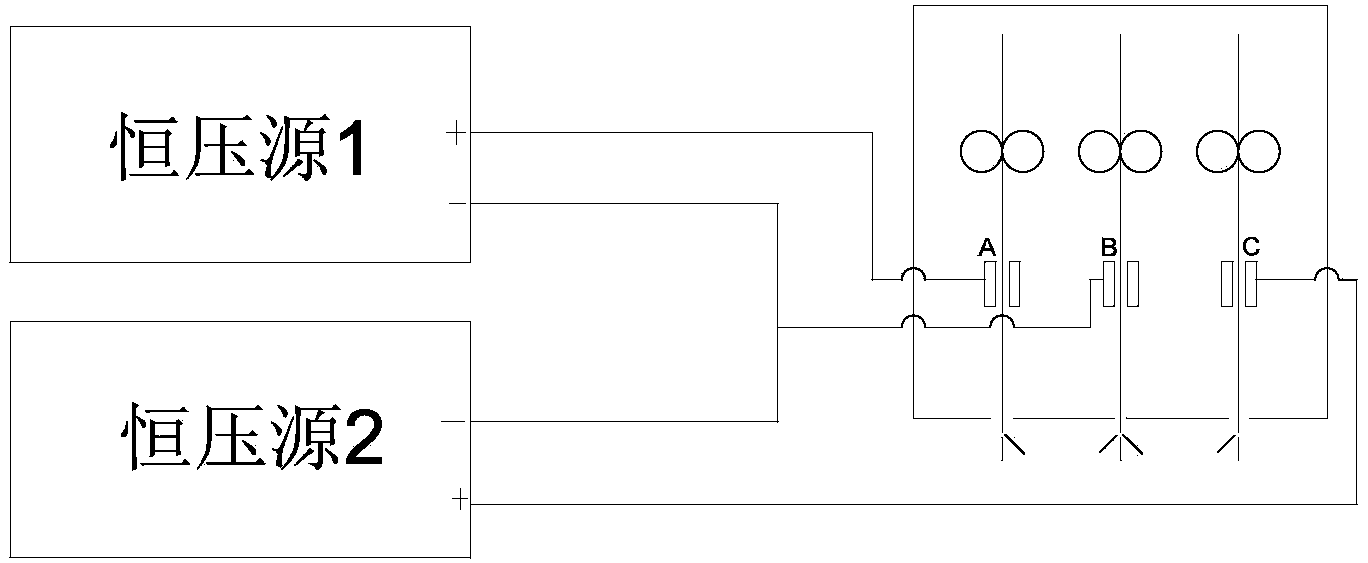

[0049] Such as Figure 4 As shown, in the second embodiment of the present invention, the circuit connected to the spraying gun has the same structure as that of the first embodiment, but the connection mode to the spraying gun is changed.

[0050] Image 6 It is the schematic diagram of the main circuit of the second embodiment. The negative output end of the DC constant voltage output circuit 3 is connected to the A connector of the three-wire spray gun, and the positive output end is connected to the B connector of the three-wire spray gun. The negative output end of the DC constant voltage output circuit 4 is connected to the C connector of the three-wire spray gun, and the positive output end is connected to the B connector of the three-wire spray gun.

[0051] Figure 9a When the power switch tubes T1 and T3 are turned on, the current flow of the primary and secondary sides of the transformer. The current flows out from the third end of the transformer B1, passes thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com