Electric-drive mechanical type variable-speed power transmission system and control system thereof

A power transmission system and electric drive technology, applied in control devices, transportation and packaging, vehicle components, etc., can solve problems such as poor heat dissipation, water leakage accidents, etc., and achieve small moment of inertia, battery protection, and large starting torque Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

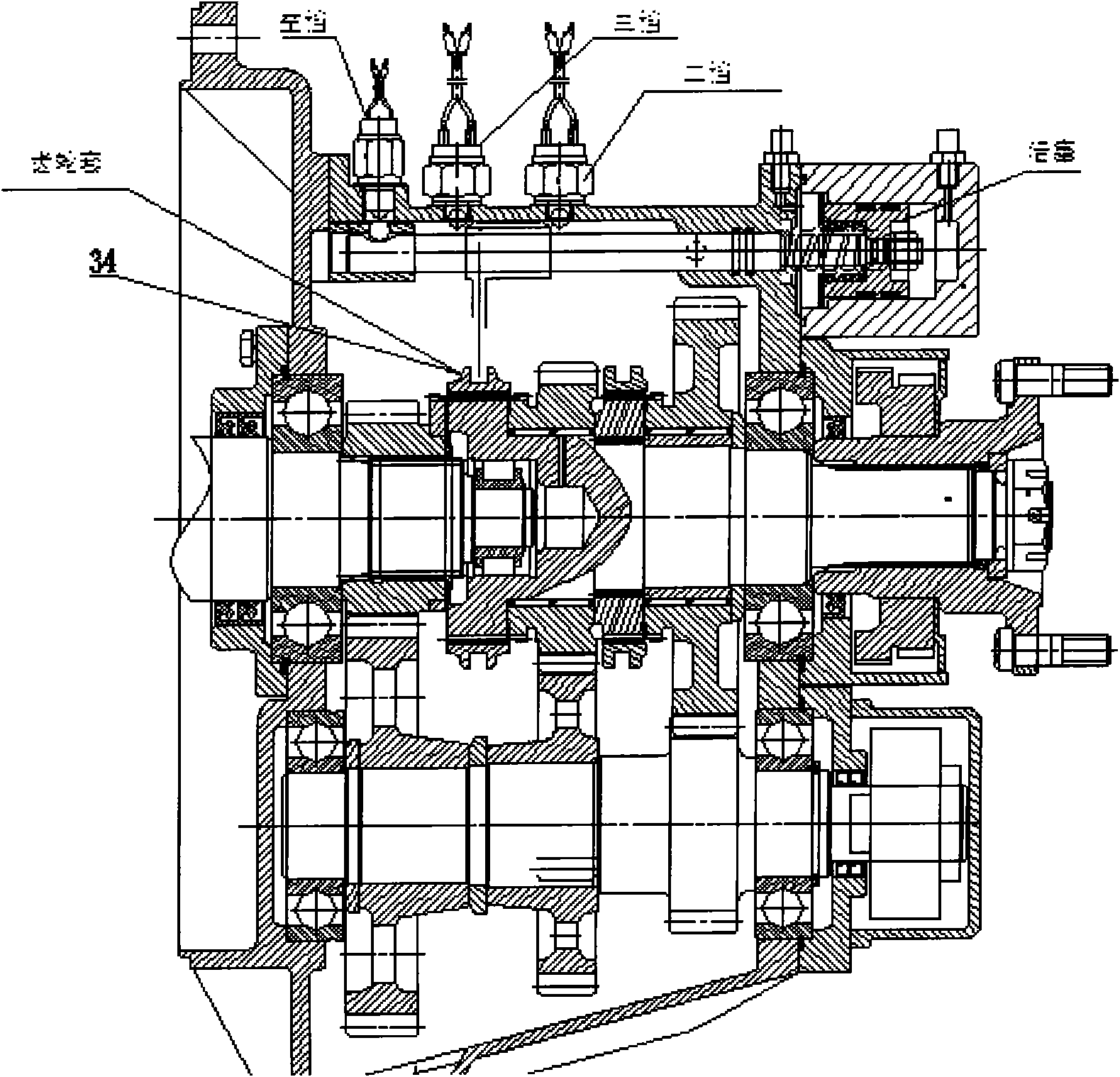

[0031] Below in conjunction with accompanying drawing, the present invention will be further described:

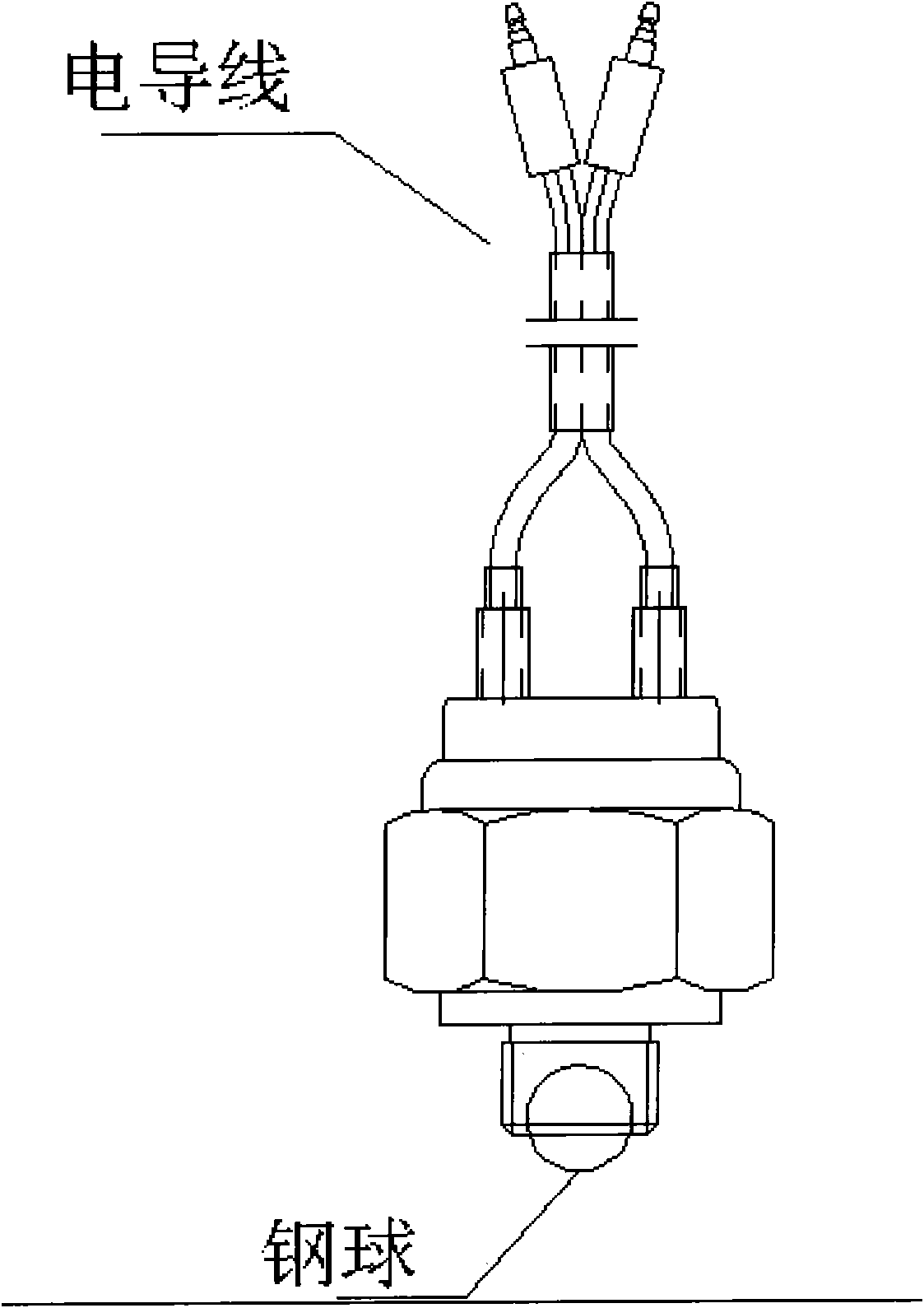

[0032] like Figure 1 to Figure 14 shown. The vehicle motor 2 is a variable frequency speed regulation motor for automobiles, which can be a three-phase AC permanent magnet synchronous motor or a three-phase AC asynchronous motor, such as a YCVF series frequency conversion speed regulation three-phase AC asynchronous or permanent magnet synchronous traction motor . A cooling water channel and a water inlet and outlet are arranged in the motor base 2 of the vehicle.

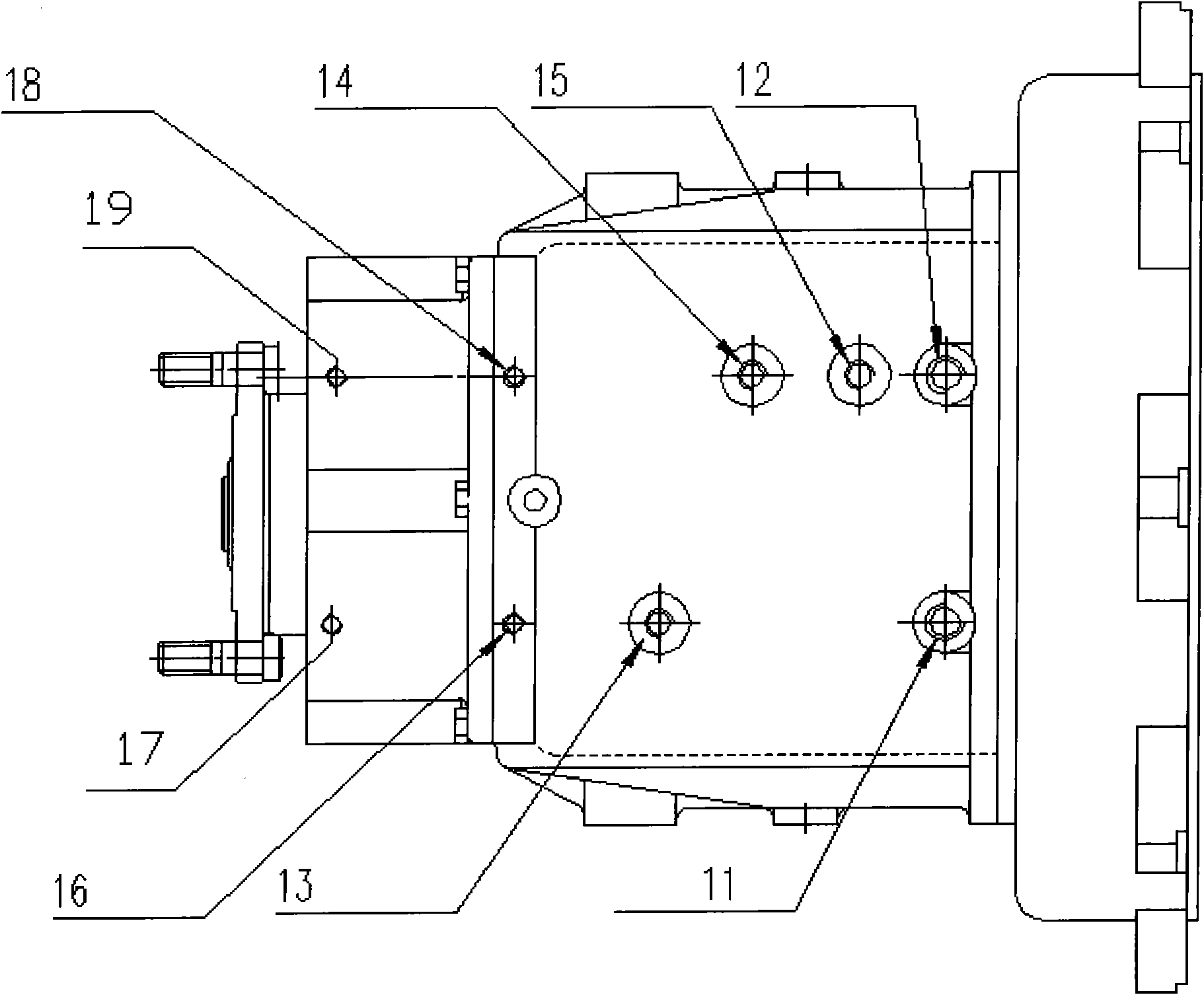

[0033] The gearbox (1) is a multi-speed gear gearbox. The gearbox 1 adopts a concave housing, and there is no end cover adjacent to the front end cover of the vehicle motor 2, and is directly fixed on the vehicle motor 2 front end cover by its edge. A clutch is omitted between the vehicle motor 2 and the gearbox (1). Gear box 1 is provided with two cylinders 30, which promote shift forks and are used for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com