Fracturing filling sand prevention model

A model and sand control technology, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., to achieve the effects of easy observation, good pressure resistance and sealing, and convenient assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following examples are used to illustrate the present invention more specifically, but the present invention is not limited to these examples.

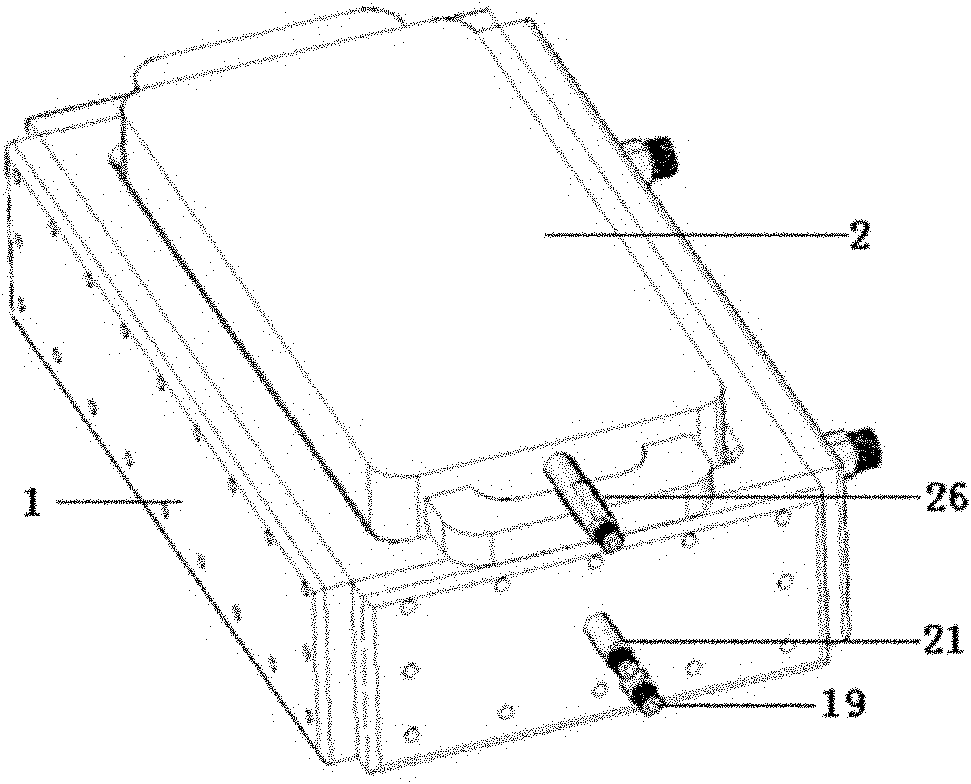

[0023] from figure 1 It can be seen that the model is divided into tank chamber 1 and top cover 2, both of which are made of stainless steel. The size of tank chamber 1 is 460mm×260mm×110mm, and the size of top cover 2 is 390mm×190mm×20mm, which is an embedded fit structure. The model, together with the medium-pressure constant flow pump with large flow rate, hydraulic pump, differential pressure sensor, air bag water tank device to provide stable liquid flow, displacement sensor, laser particle size analyzer and standard sieve, centrifuge, balance, etc., form a complete set experimental system.

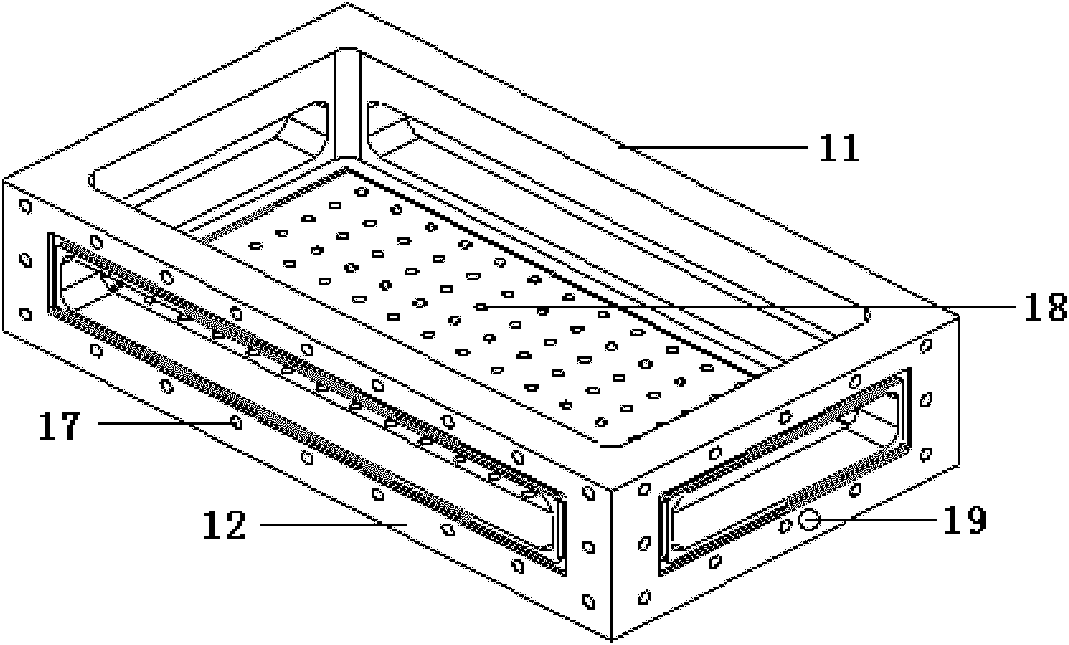

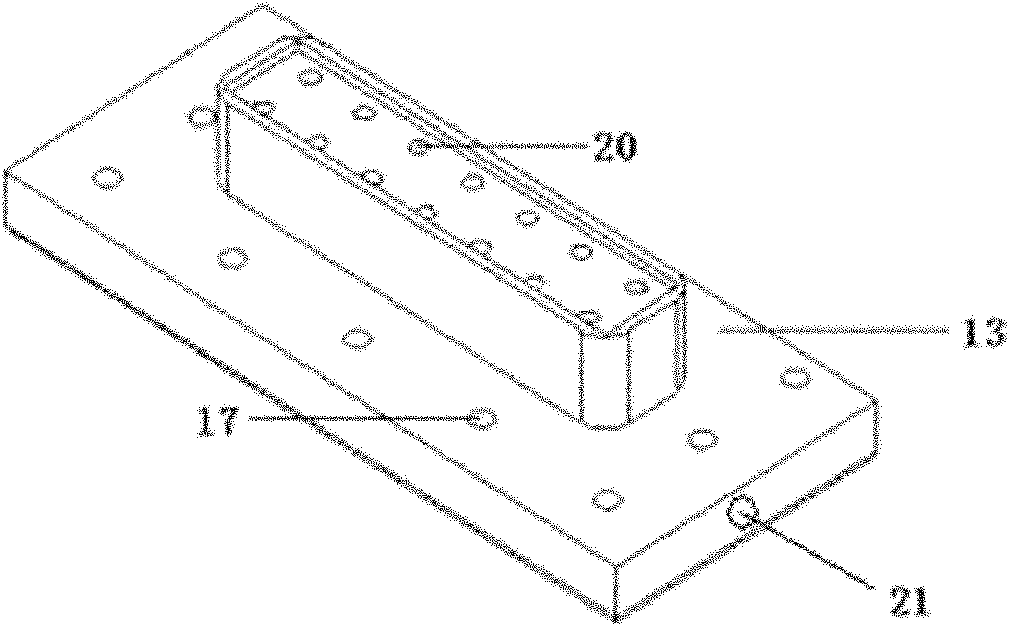

[0024] from Figure 2-6 It can be seen that the tank chamber 1 is a detachable structure, including a frame 11, a bottom 12 and four side walls 13, 14, 15, 16, front, rear, left and right, wherein the bottom 12 and the frame 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com