Digital direct-current igniter for motorcycle

A DC point and motorcycle technology, applied in the direction of automatic control, automatic control, with capacitive energy storage devices, etc., can solve the problems that ordinary DC igniters cannot meet the requirements of high-speed performance and cannot be interchanged, and reach the economic speed range Effects of expansion, vehicle speed increase, and increase rate of charge voltage increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

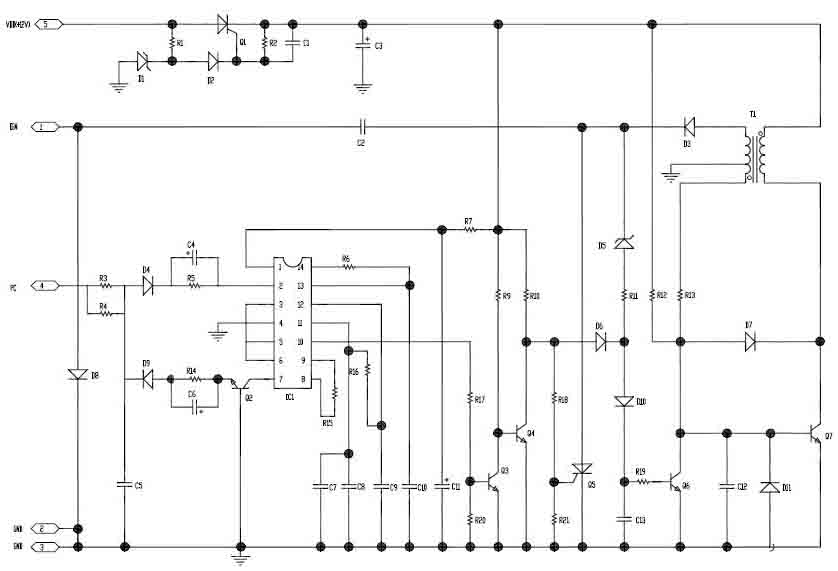

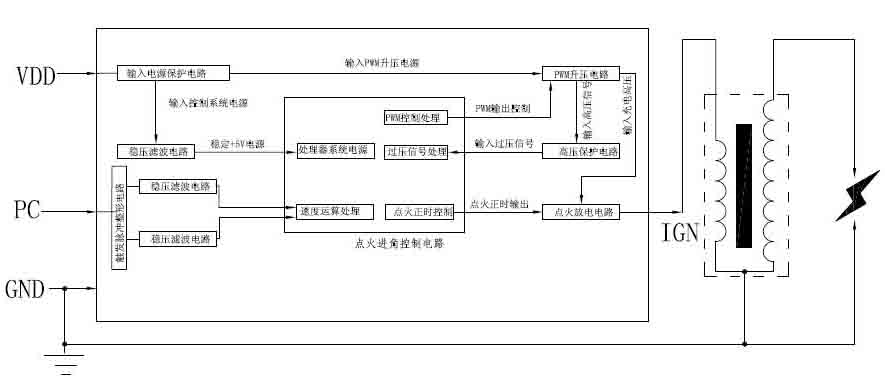

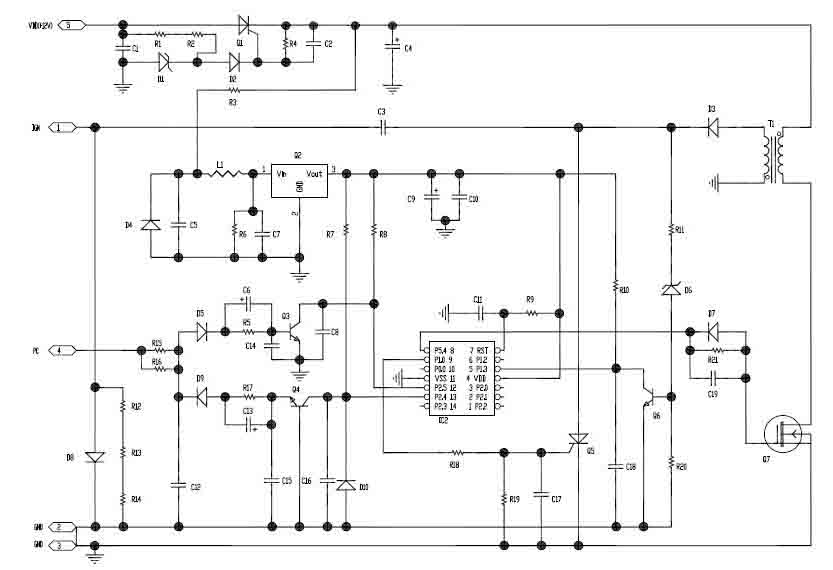

[0010] Such as figure 2 As shown, the motorcycle digital DC igniter includes a trigger pulse shaping circuit, a negative pulse separation circuit and a positive pulse separation circuit, an ignition timing control circuit, a boost circuit composed of a step-up transformer and a switching power tube as the core, and an ignition discharge circuit. Such as image 3 As shown, the DC working power supply of the ignition timing control circuit is provided by the voltage stabilization filter circuit, and the voltage stabilization filter circuit is composed of resistors R3, R6, capacitors C5, C7, C9, C10, diode D4, inductor L1 and three-terminal regulator Q2 The composition improves the stability of the power supply of the igniter control system and the anti-interference of the system. The ignition timing control circuit takes the single-chip processor IC2 as the core, and the negative pulse separation circuit consists of the detection diode D9, the acceleration capacitor C13, the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com