Measuring loads on wind turbine blades

A technology of wind turbine blades and blades, which is applied in the field of sensor systems, can solve the problems of sensitivity and affecting the aerodynamic characteristics of blades, and achieve the effect of reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

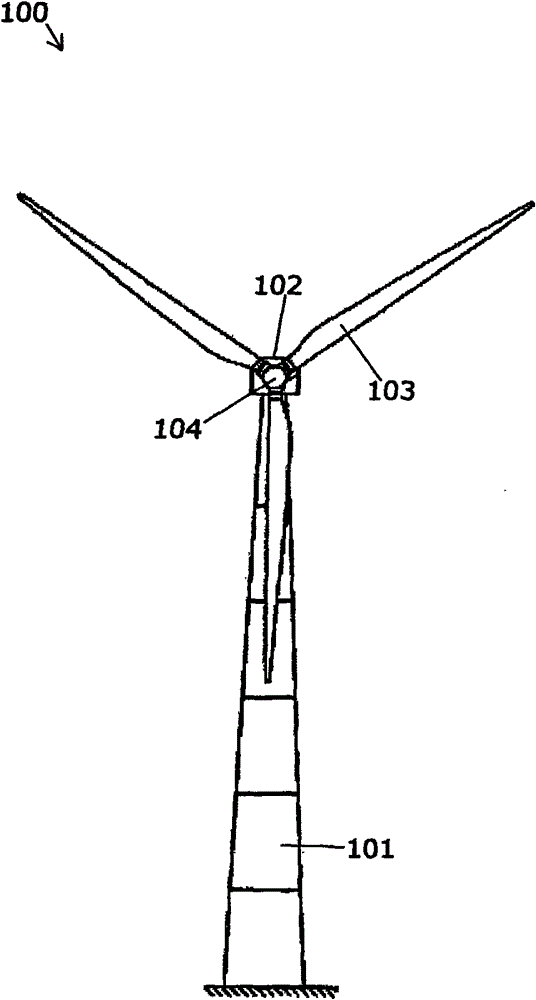

[0049] figure 1 A wind turbine generator 100 is shown comprising a tower 101 and a nacelle 102 . The rotor blades 103 are fixed to the hub 104 . The assembly of rotor blades 103, ie the rotor, can be turned by the action of the wind. Thus, the wind-generated rotational energy of the rotor blades 102 can be transferred via the hub to the generator in the nacelle. Thus, the wind turbine generator 100 is able to convert wind energy into mechanical energy by means of the rotor blades and subsequently into electrical energy by means of the generator.

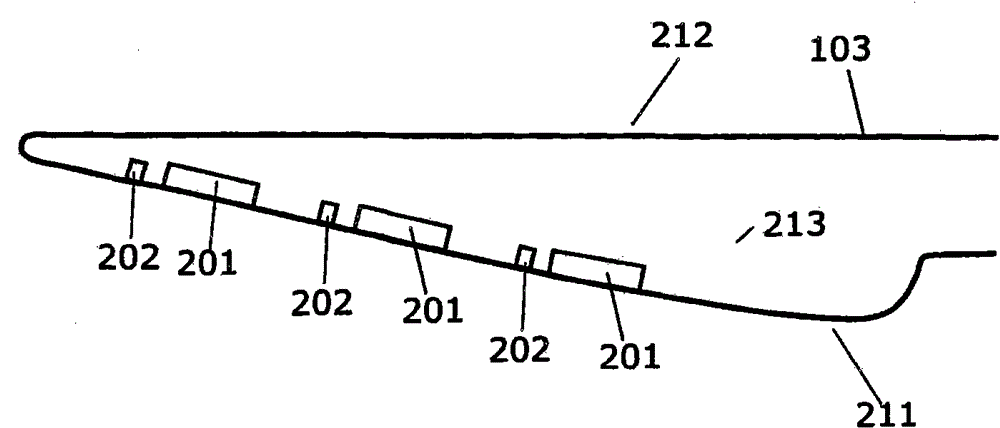

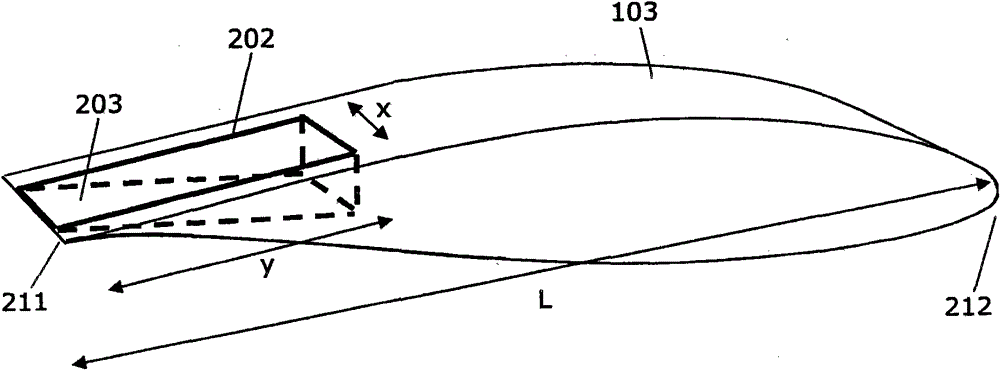

[0050] The rotor blade 103, or just the blade 103, includes, but is not limited to, an elongated structure having an airfoil profile adapted to provide aerodynamic lift during relative motion in the air.

[0051] The blade 103 may be provided with an aerodynamic or lift changing structure (not shown), for example, a pivotable trailing edge flap, a deformable trailing edge flap, or a device that changes the aerodynamic characterist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com