Automatic variable rape seeding control system

An automatic variable and control system technology, applied in the field of control system research, can solve problems such as affecting production, time-consuming and labor-intensive, and large ground wheel resistance, and achieve the effect of convenient and simple adjustment of seeding rate, simple adjustment of seeding rate, and reasonable overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

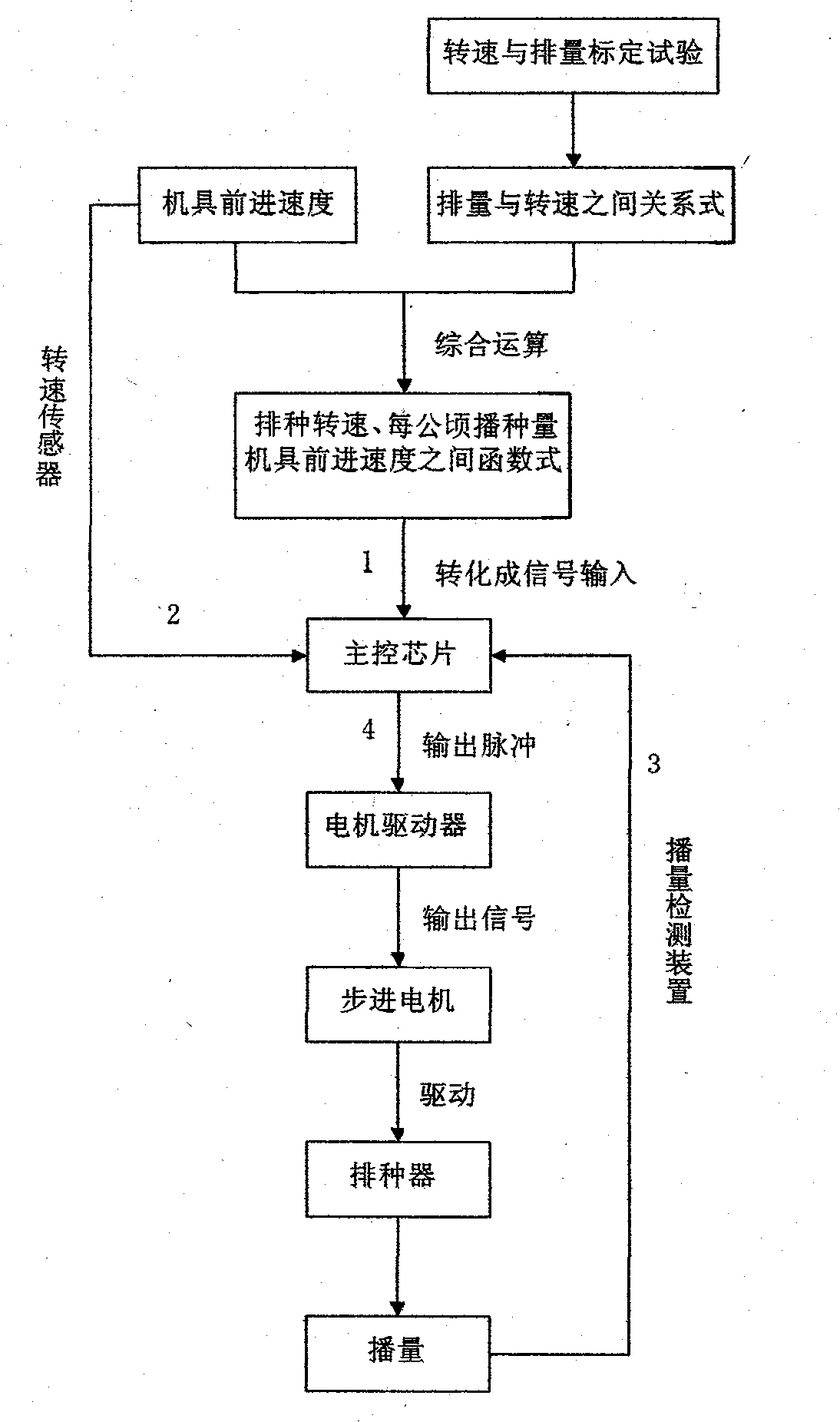

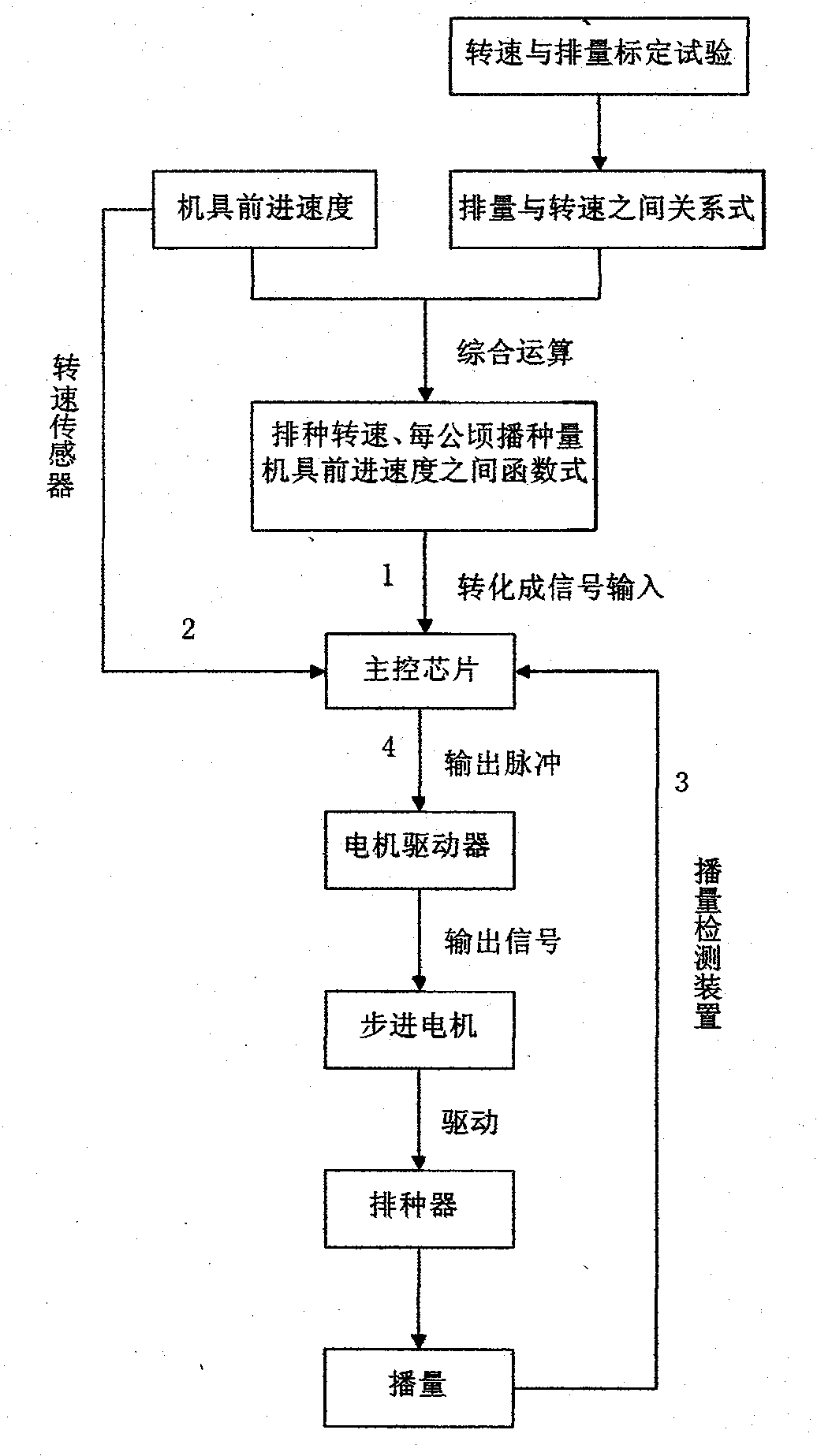

[0012] In order to make the technical means, objectives and effects of the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0013] The control system adopted in the present invention has three inputs and one output. The three inputs include the input 1 of the feed rate signal, the input 2 of the forward speed signal of the work tool, and the input 3 of the feed rate detection signal. The main control chip synthesizes the three inputs. After analysis, a pulse 4 is output to the driver, and the driver regulates the speed of the stepping motor, and the stepping motor directly drives the seed metering device for seeding, so as to meet the requirement of variable sowing.

[0014] Input 1 of the sowing rate signal: convert the functional relationship between the seeding speed, the seeding rate per hectare, and the forward speed of the implement to the main control chip; input 2 of the forward spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com