Organic light-emitting device and production method thereof

An electroluminescent device and a luminescent technology, which are applied in the fields of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the high requirements for doping concentration and doping thickness control, and the preparation of doped intermediate connection layers. Problems such as complex process and unfavorable mass production achieve the effects of reducing current density, simplifying the preparation process and controlling costs, and improving luminous efficiency and lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

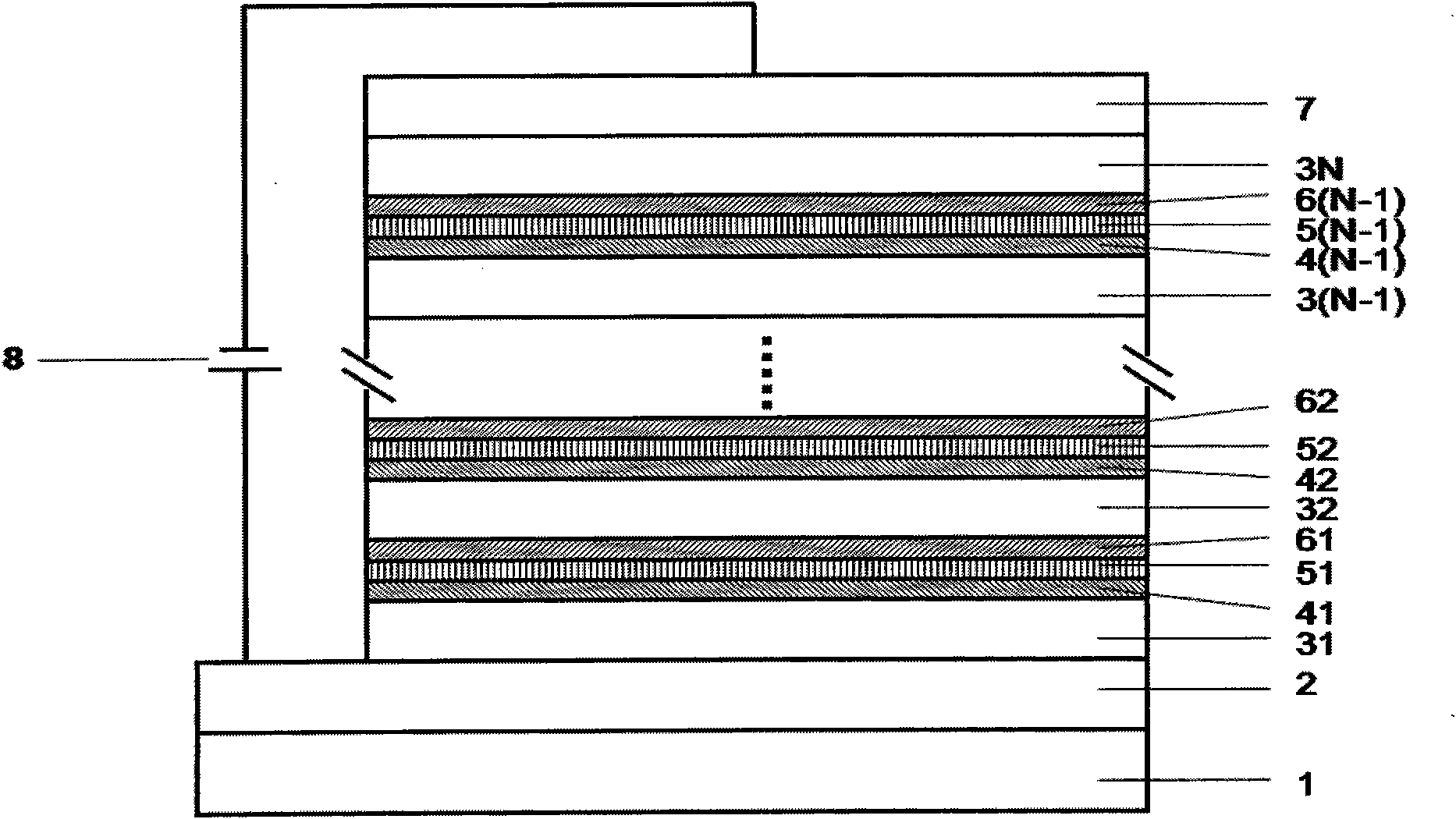

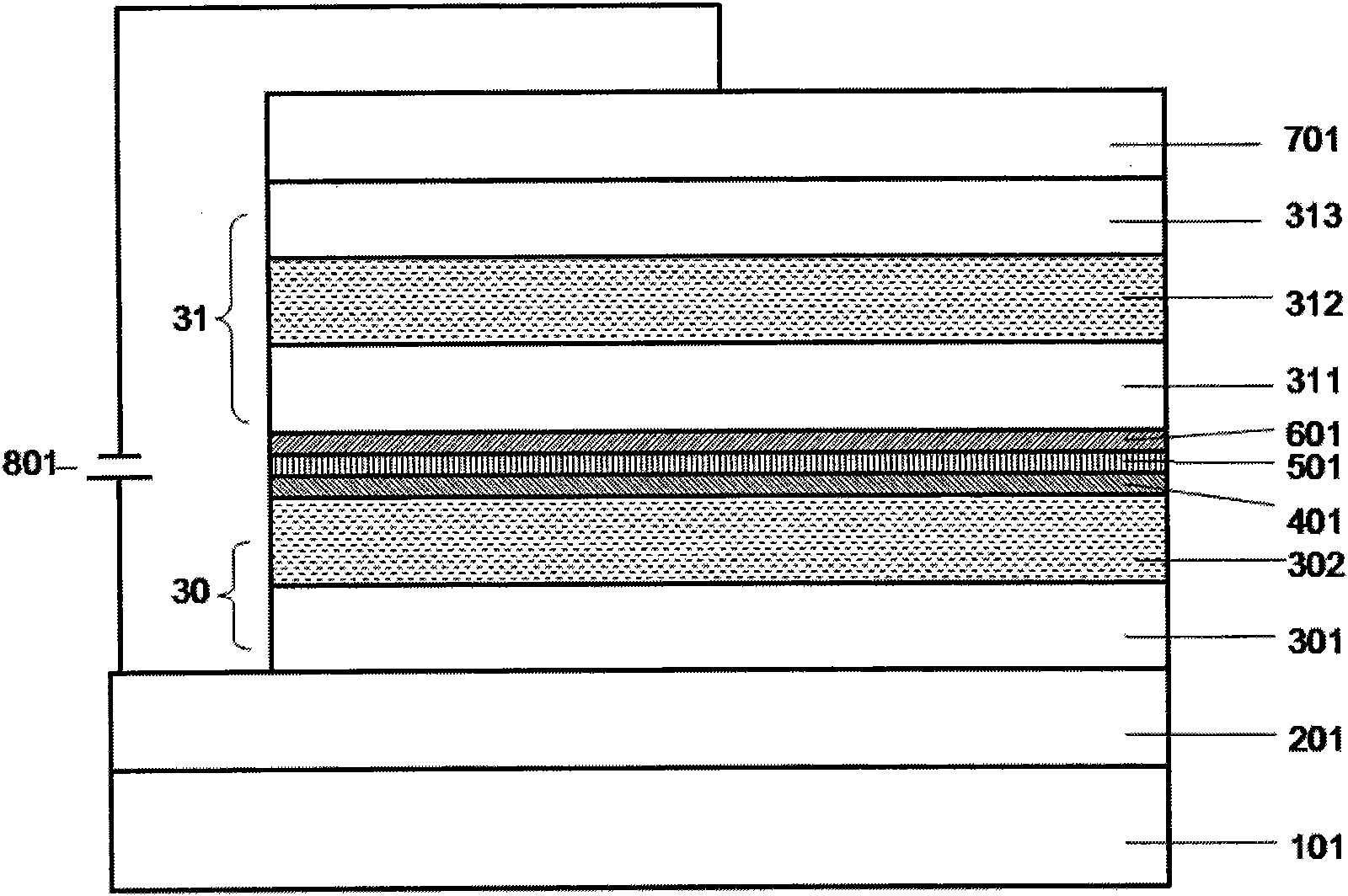

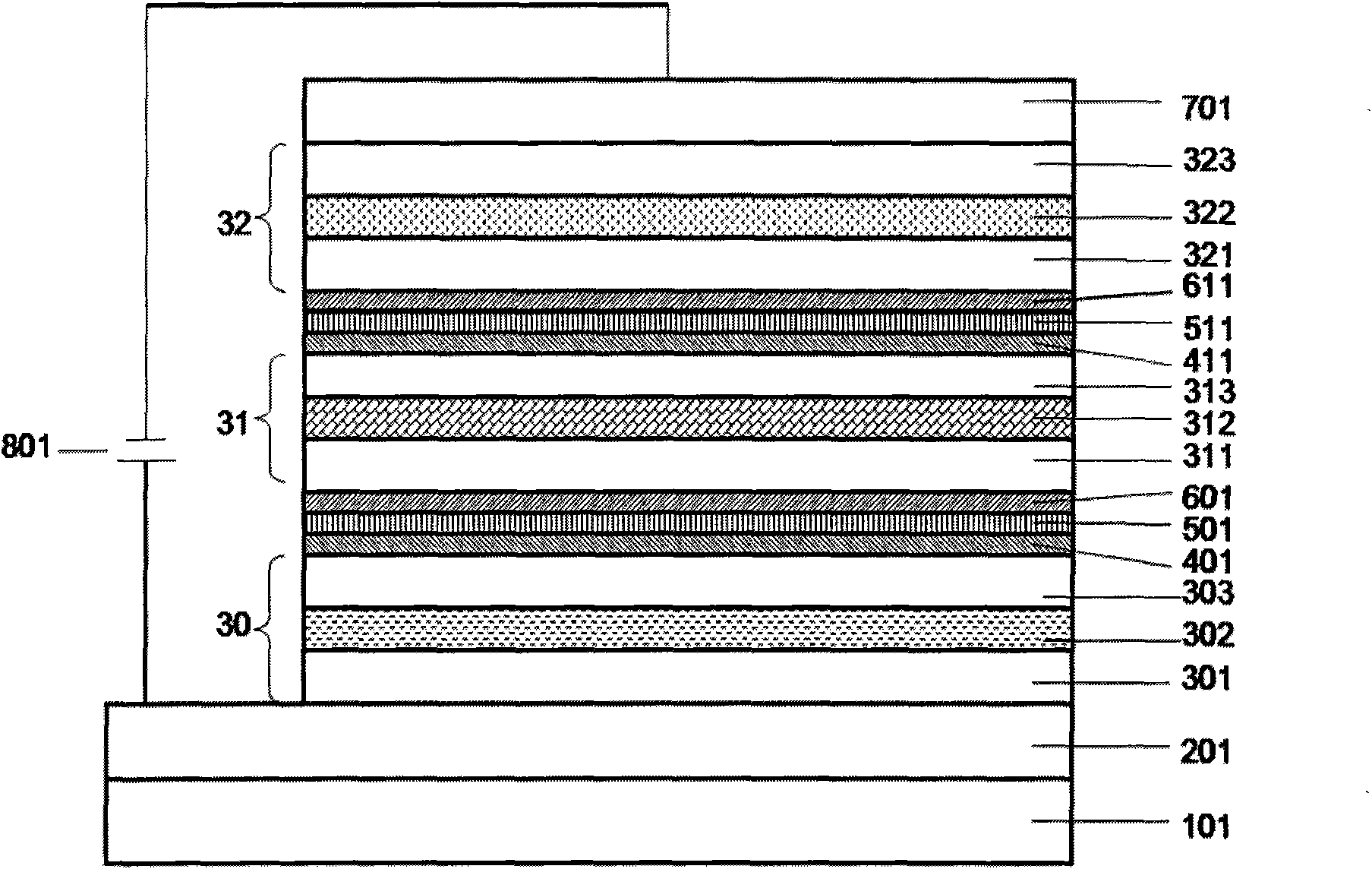

[0099] Such as figure 2 As shown, the ultra-thin connection layer in the structure of the device includes an organic ultra-thin layer 401 as a buffer layer, an N-type metal ultra-thin layer 501 , and a P-type metal compound ultra-thin layer 601 .

[0100] The organic ultra-thin layer of the device as a buffer layer is Bphen, the N-type metal ultra-thin layer is Mg, and the P-type metal compound ultra-thin layer is V 2 o 5 .

[0101] The first electroluminescent unit 30 in the structure of the device includes a hole transport layer 301 and a doped layer 302 that emits blue light.

[0102] The second electroluminescent unit 31 in the structure of the device includes a hole transport layer 311 , a doped layer 312 emitting blue light, and an electron transport layer 313 .

[0103] The blue-emitting phosphorescent material of the device is FIrPic, the phosphorescent host material is CBP, the hole transport material is NPB, and the electron transport material is Alq 3 , The cat...

Embodiment 2

[0118] Such as figure 2 As shown, the ultra-thin connection layer in the structure of the device includes an organic ultra-thin layer 401 as a buffer layer, an N-type metal ultra-thin layer 501 , and a P-type metal compound ultra-thin layer 601 .

[0119] The organic ultra-thin layer of the device as a buffer layer is CuPc, the N-type metal ultra-thin layer is Li, and the P-type metal compound ultra-thin layer is FeCl 3 .

[0120] The first electroluminescent unit 30 in the structure of the device includes a hole transport layer 301 and a doped layer 302 that emits green light.

[0121] The second electroluminescent unit 31 in the structure of the device includes a hole transport layer 311 , a doped layer 312 emitting green light, and an electron transport layer 313 .

[0122] The phosphorescent material of the device that emits green light is Ir(ppy) 3 , the phosphorescent main material is UGH2, the hole transport material NPB, the electron transport material TPBi, and th...

Embodiment 3

[0126] Such as figure 2 As shown, the ultra-thin connection layer in the structure of the device includes an organic ultra-thin layer 401 as a buffer layer, an N-type metal ultra-thin layer 501 , and a P-type metal compound ultra-thin layer 601 .

[0127] The organic ultra-thin layer of the device as a buffer layer is BCP, the N-type metal ultra-thin layer is Ca, and the P-type metal compound ultra-thin layer is M O o 3 .

[0128] The first electroluminescent unit 30 in the structure of the device includes a hole transport layer 301 and a doped layer 302 that emits red light.

[0129] The second electroluminescent unit 31 in the structure of the device includes a hole transport layer 311 , a doped layer 312 emitting red light, and an electron transport layer 313 .

[0130] The red-emitting phosphorescent material of the device is Ir(piq) 3 , the phosphorescent main material is MCP, the hole transport material NPB, the electron transport material TPBi, and the cathode laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com