Olefin polymerization catalyst and olefin polymerization method using the same

An olefin polymerization and catalyst technology, applied in the field of olefin polymerization catalysts, can solve the problems of increasing the production cost of polyolefins, difficult to manufacture high-molecular-weight polyolefins, etc., and achieve the effects of increasing output, minimizing manufacturing time and manufacturing steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

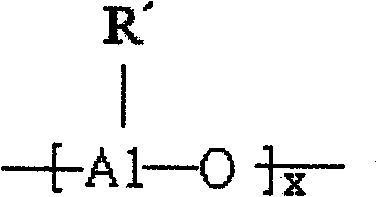

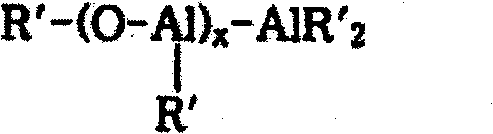

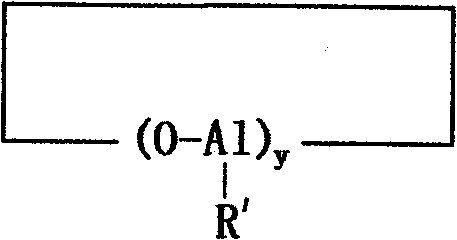

Method used

Image

Examples

Embodiment 1

[0078] The solution polymerization of embodiment 1 polyethylene

[0079] In a 500 ml nitrogen atmosphere flask, 1.5 mg (0.013 mmol) of indene (Ind), 0.83 mg (0.013 mmol) of n-butyllithium and 10 ml of methylaluminoxane (MAO, Albemarle company, 10% toluene solution) were mixed and stirred for 1 hour, then 1.57 mg (0.006 mmol) of cyclopentadienyl zirconium trichloride (Zr=6.0 μmol, the molar ratio of Al / Zr was 2500) was added and heated at 60° C. Stir for 60 minutes. After the stirring was completed, the obtained catalyst solution was used for polymerization.

[0080] A 1 L stainless steel autoclave reactor with a jacket for supplying cooling water to remove impurities was purged with isobutane (once) and ethylene (five times) at 85°C to remove impurities and then cooled to room temperature. Control the polymerization temperature. 300 ml of dry hexane and 0.5 mmol of triisobutylaluminum (TIBAL, impurity scavenger) were added to the reactor at room temperature and heated to a ...

Embodiment 2

[0082] A. Catalyst Preparation

[0083] In a 500ml nitrogen atmosphere flask, 144mg (0.49mmol) of bis(indenyl)ethane, 40mg (0.63mmol) of butyllithium and 22ml of methylalumoxane (MAO, Albemarle company, 10% toluene solution ) were mixed and stirred for 2 hours, then 49 mg (0.157 mmol) of indenyl zirconium trichloride was added and stirred at 50° C. for 120 minutes. After the stirring was completed, 5 g of silica (Sylopol 948) calcined at 220° C. was added to the prepared catalyst solution, ultrasonic waves were applied for 1 hour, and the supernatant was discarded. The remaining solid particles were washed (once) with hexane and dried in vacuo to obtain the supported catalyst as a free-flowing solid powder.

[0084] B. Copolymerization of ethylene / 1-hexene

[0085] A jacketed 2 L stainless steel autoclave reactor was purged with isobutane (once) and ethylene (five times) to remove impurities at 110°C and cooled to 80°C, with the jacket used to supply cooling water to contro...

Embodiment 3

[0087] A. Catalyst Preparation

[0088] In a 500ml nitrogen atmosphere flask, 61ml (60.85mg; 0.524mmol) of indene, 35.5mg (0.57mmol) of n-butyllithium and 22ml of methylalumoxane (MAO, Albemarle, 10% toluene solution ) were mixed and stirred for 1 hour, then 85 mg (0.267 mmol) of n-butylcyclopentadienyl zirconium trichloride was added and stirred at 60° C. for 60 minutes. After the stirring was completed, 5 g of silica (Sylopol 948) calcined at 220° C. was added to the prepared catalyst solution, ultrasonic waves were applied for 1 hour, and the supernatant was discarded. The remaining solid particles were washed (once) with hexane and dried in vacuo to obtain the supported catalyst as a free-flowing solid powder.

[0089] B. Copolymerization of ethylene / 1-hexene

[0090] Polymerization was carried out according to the polymerization method of Example 2 and continued for 74 minutes except that 101 mg of the catalyst prepared in the above step was used, thereby obtaining 195 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com