Hot radiator storing yard generating-apparatus

A high-temperature heat release and yard power generation technology, applied in solar thermal power generation, wind power generation, engines, etc., can solve problems such as difficult power generation, heat limitation, and low heat density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0130] Hereinafter, preferred embodiments for carrying out the present invention will be described with reference to the drawings.

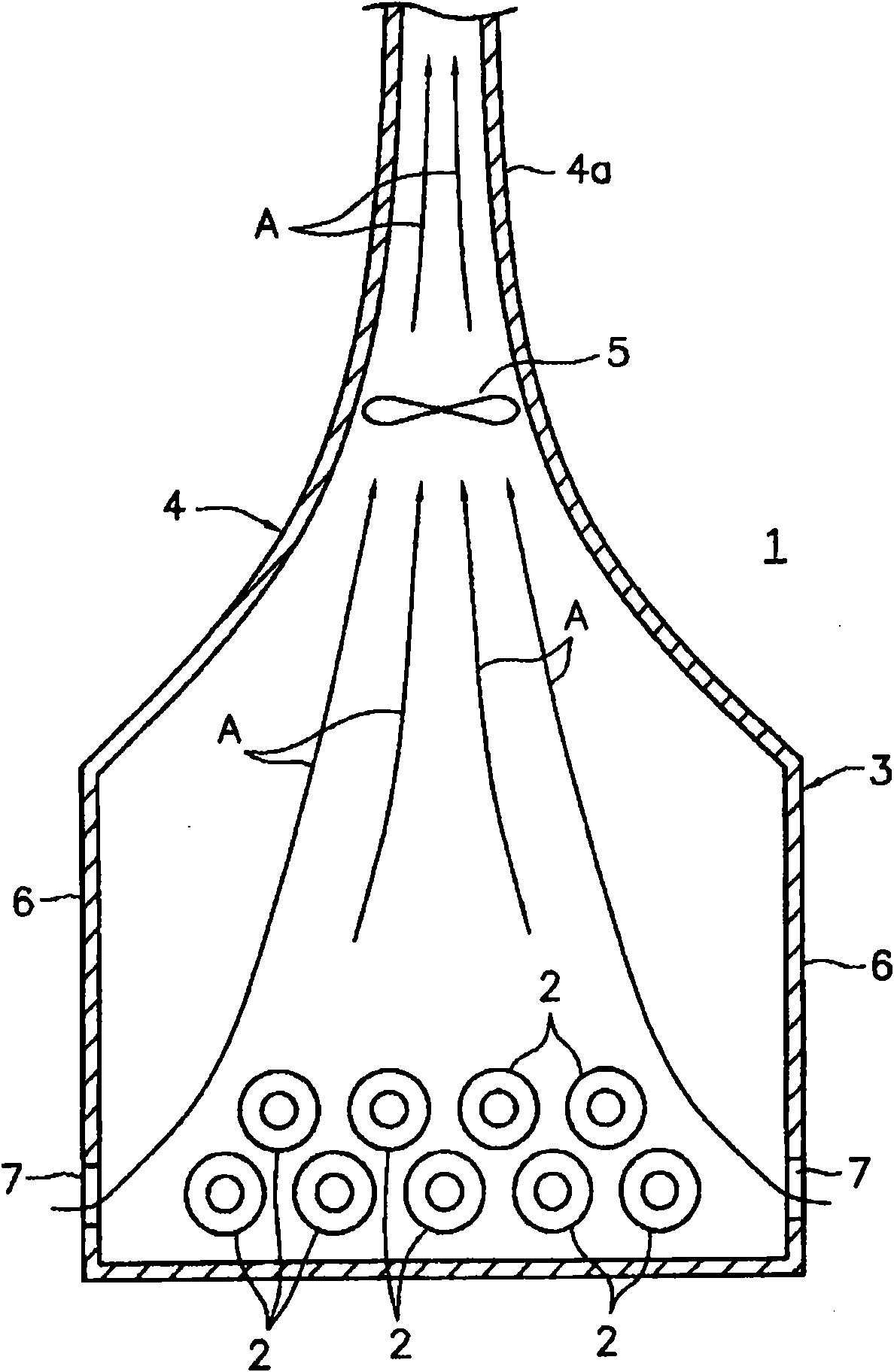

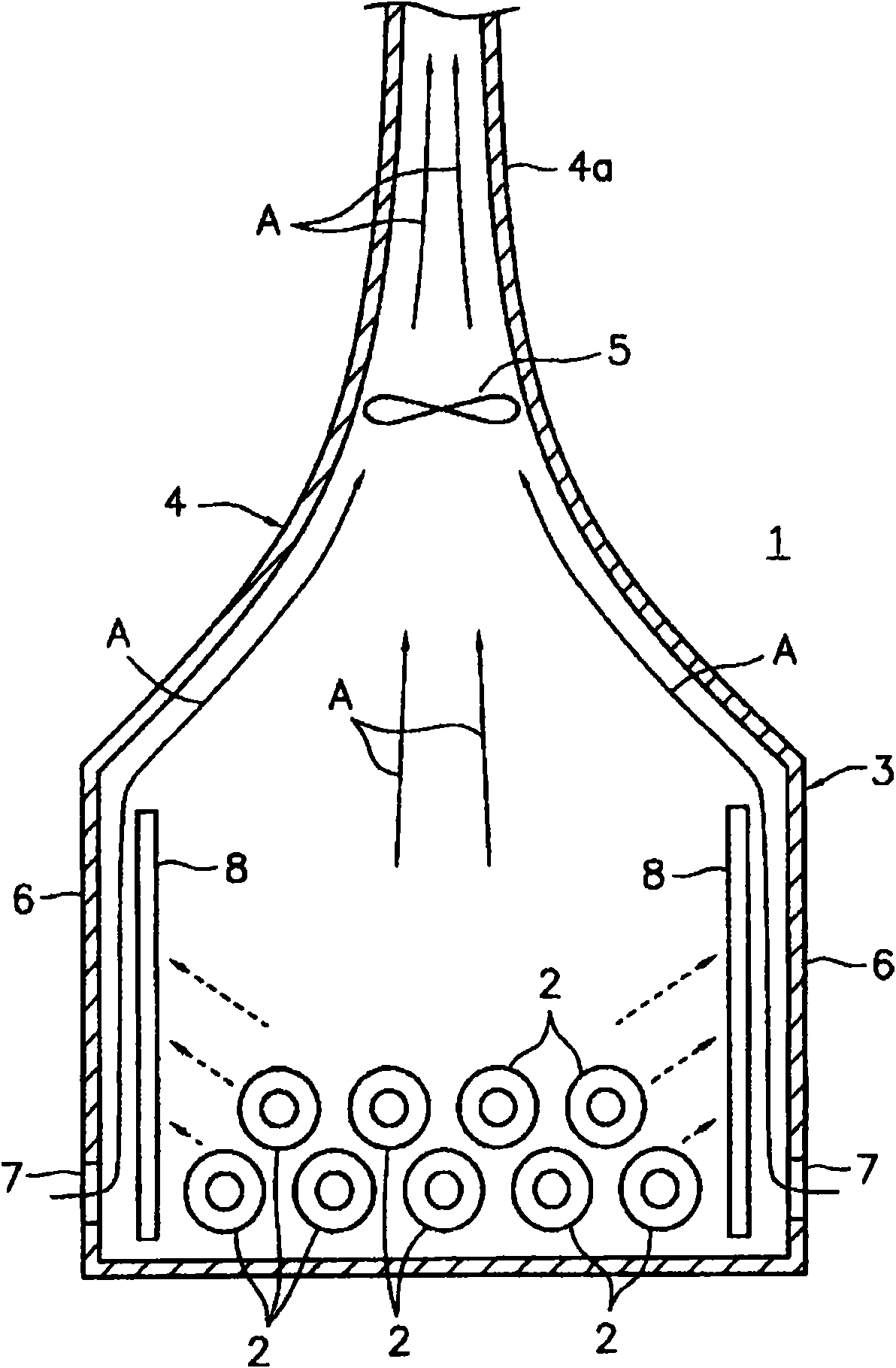

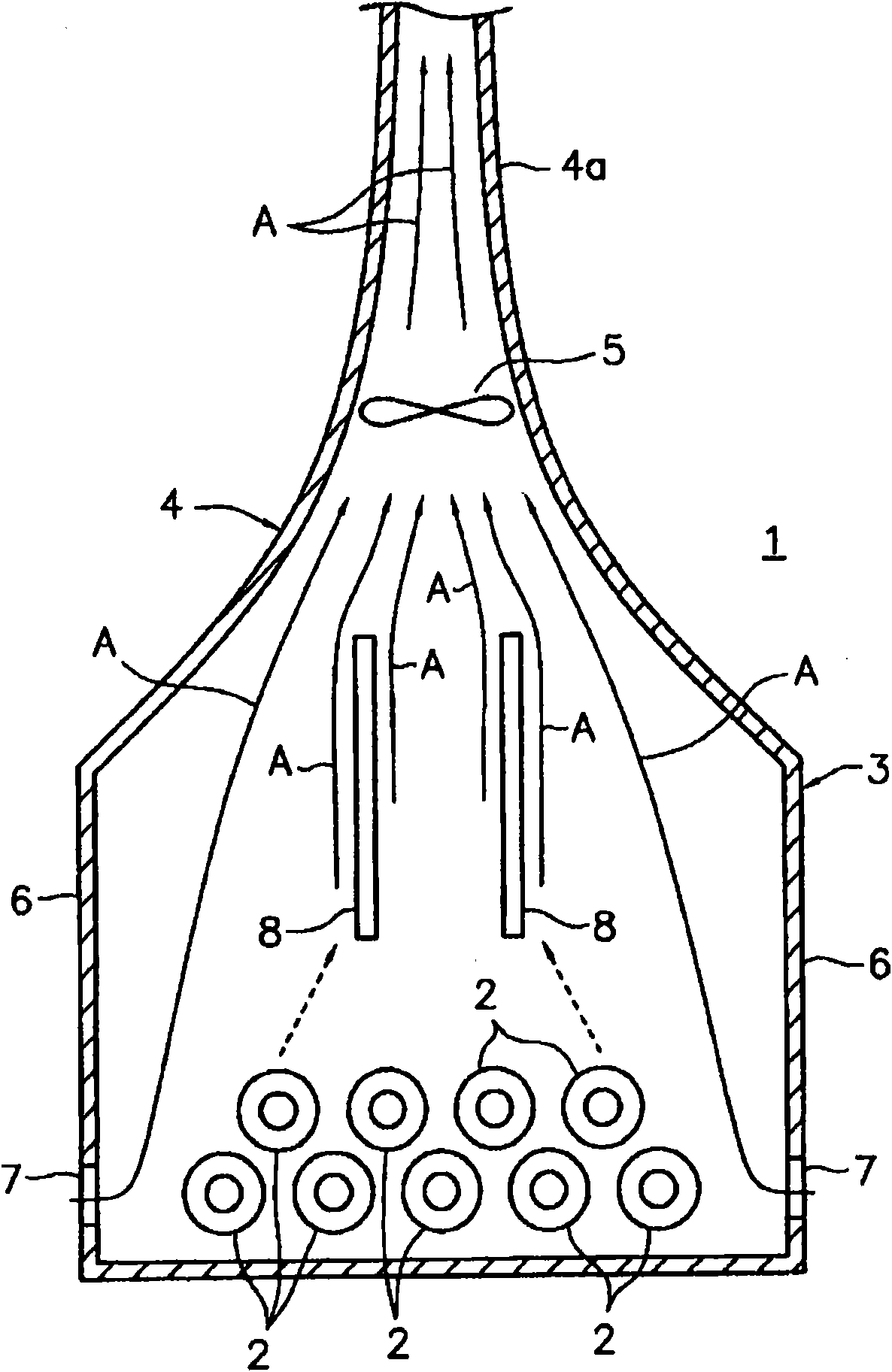

[0131] figure 1 As one embodiment of the high-temperature exothermic object storage yard power generation device of the present invention, it is shown that it is applied to a steel intermediate product as a high-temperature exothermic object manufactured by a hot rolling facility in an iron and steel joint venture steel company or the like for temporary storage. When the hot-rolled coil 2 is stored in the coil yard 1 as a high-temperature exothermic object, it has the following configuration.

[0132] That is, on the ceiling part of the coil stockyard building 3 that will temporarily store the hot-rolled coil 2 manufactured with the input of heat by the hot-war equipment before being transferred to the next process, there is a structure that makes the lower part approximately A chimney 4 having a square pyramid shape and a cylindrical portion 4a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com