An ultra-thin high-temperature high-efficiency photovoltaic cell panel

A technology of photovoltaic panels and photovoltaic cells, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of small power generation, low power generation efficiency, and inability to use concentrated light tracking power generation devices, etc., to achieve enhanced power generation capacity, power generation The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

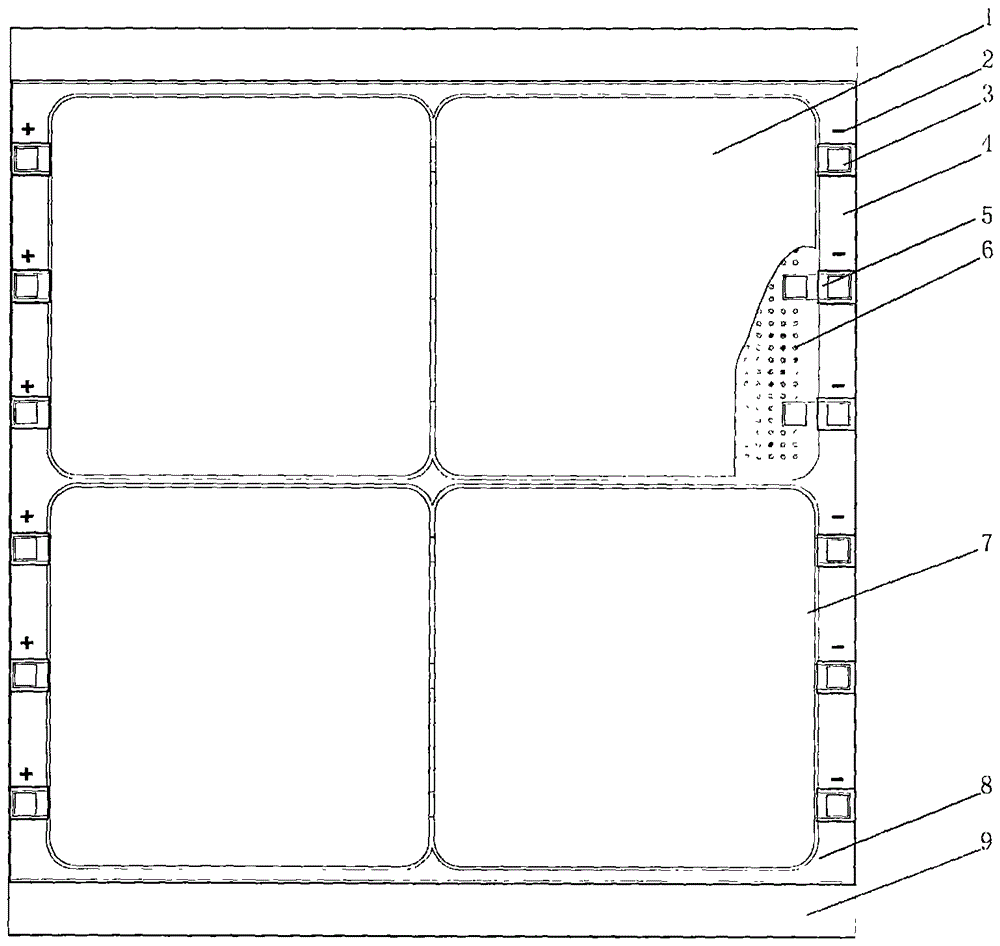

[0027] Referring to the accompanying drawings, the present invention is an ultra-thin high-temperature high-efficiency photovoltaic battery panel, which includes: photovoltaic glass 1, silk screen characters 2, copper plating + hanging printing paste solder 3, glass fiber board 4, solder mask 5, heat conduction Holes 6, monocrystalline silicon solar cells 7, glass welding layer 8, and aluminum substrate 9; the aluminum substrate 9 is used as the bottom plate of the photovoltaic cell, and the glass fiber plate 4 with heat conduction holes is attached to the bottom plate of the photovoltaic cell, and the heat conduction holes 6 are filled with Thermally conductive silicone grease, through printing, copper plating, solder resist, printing and hanging printing paste soldering 3 processes to form the photovoltaic cell panel substrate, hanging printing met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com