Multi-point forming device for plate

A multi-point forming and plate technology, applied in the field of sheet metal stamping, can solve the problems of high device cost, high device cost, difficult to meet the forming of complex parts, etc., to achieve convenient composition and adjustment, simple adjustment method, and restrain the sheet metal from rising. wrinkle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

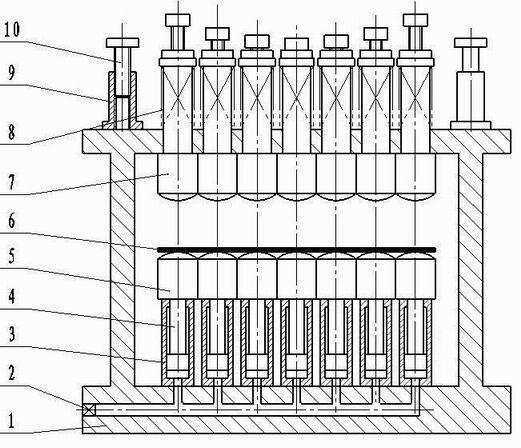

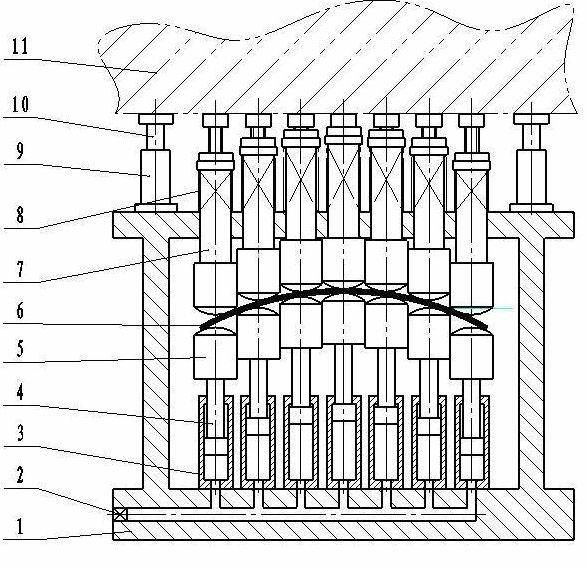

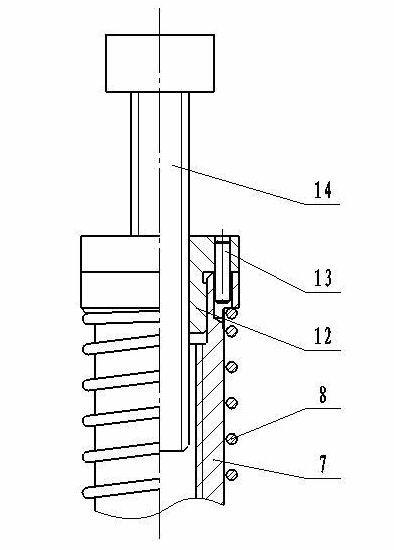

[0021] From figure 1 , figure 2 As can be seen in the figure, a plate multi-point forming device includes a formwork 1, a number of upper pressure head pressing units installed on the upper plate of the formwork 1, and a number of lower indenter support units installed on the lower plate of the formwork. The upper pressing head pressurizing unit is composed of an upper pressing head 7, a spring 8 and a stroke adjustment assembly. The upper pressing head 7 is installed in the positioning hole of the upper plate of the formwork 1 and can move up and down along the axis of the hole. The spring 8 is installed Between the upper ram 7 and the upper plate of the mold frame 1, it is used for the return stroke of the upper ram press unit after the pressing is completed; the lower ram support unit is composed of the lower ram 5, the plunger 4 and the hydraulic cylinder 3, The hydraulic cylinder 3 is fixed on the lower plate of the formwork 1, and the plunger 4 is connected with the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com