Method for preparing organosilane crosslinked polyethylene with long quality guarantee period by solid one-step process

A technology of silane cross-linking and shelf life, which is applied in the field of solid-phase one-step production of silane cross-linked polyethylene, can solve the problems of cross-linked polyethylene scrapping, low cross-linking degree of silane cross-linked polyethylene, and inability to cross-link, so as to prevent Effect of condensation reaction, good processability and degree of crosslinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

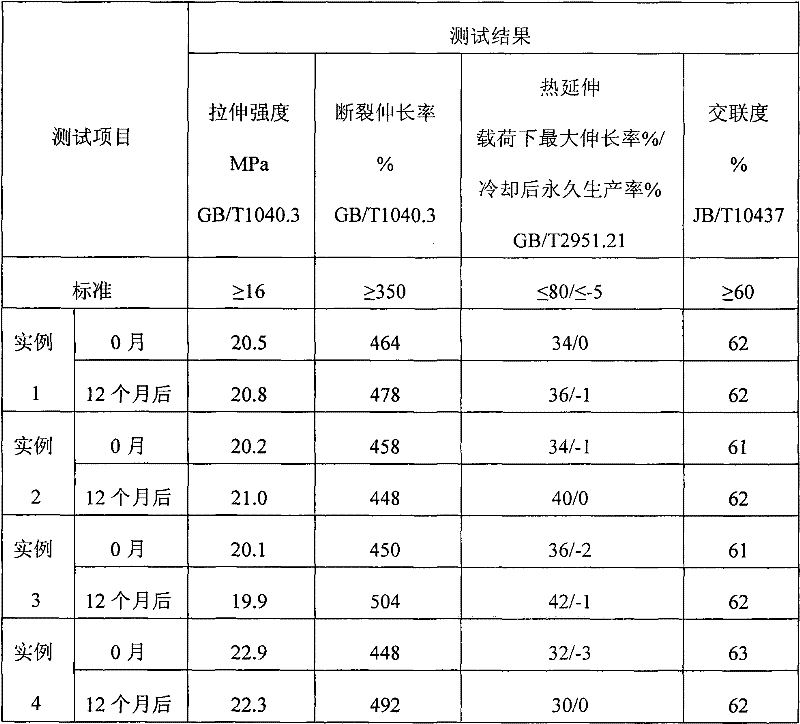

Examples

Embodiment 1

[0025] 1 part of 4-amino-α, α, 4-trimethyl-cyclohexanementamine, 1 part of formic acid, 3 parts of salicylamidophthalimide, 0.5 parts of tetrakis (3-( 3', 5'-di-tert-butyl-4-hydroxyphenyl) propionate) pentaerythritol ester, 100 parts of polyethylene resins are kneaded at 130 DEG C in a kneader, extruded and granulated to obtain catalyst masterbatch particles, and then The obtained catalyst master batch particles are immersed in molten paraffin, stirred for 100 seconds, then filtered, the catalyst master batch particles are collected, and dried to obtain catalyst master batch particles coated with paraffin wax on the surface;

[0026] Then, the above-mentioned catalyst masterbatch particles wrapped in paraffin, 95 parts of polyethylene resins, 5 parts of polypropylene resins, 2 parts of vinyltriisopropoxysilane, 1 part of dicumyl peroxide and 0.5 part of tetra( 3-(3',5'-di-tert-butyl-4-hydroxyphenyl) propionate) pentaerythritol ester is mixed at room temperature to obtain the p...

Embodiment 2

[0029] 1 part of 1,4-diamino-cyclohexanementamine, 1 part of formic acid, 3 parts of salicylamidophthalimide, 0.5 parts of tetrakis(3-(3',5'-di tert-butyl-4-hydroxyphenyl) propionate) pentaerythritol ester, 100 parts of polyethylene resins were kneaded at 115°C in a kneader, extruded and granulated to obtain catalyst masterbatch particles, and then the obtained catalyst masterbatch particles were impregnated In molten paraffin, stirring for 100 seconds, then filtering, collecting catalyst masterbatch particles, drying, obtaining catalyst masterbatch particles coated with paraffin wax on the surface;

[0030] Then the above-mentioned catalyst masterbatch particles wrapped with paraffin and 100 parts of polyethylene resin, 5 parts of polypropylene resin, 2 parts of vinyltriisopropoxysilane, 1 part of dicumyl peroxide and 0.5 part of four (3- (3',5'-di-tert-butyl-4-hydroxyphenyl)propionate)pentaerythritol ester can be mixed uniformly at room temperature.

[0031] The amount by w...

Embodiment 3

[0033] The difference between this embodiment and Example 1 is that low molecular weight polyethylene is used to wrap the protective agent.

[0034] 1 part of 4-amino-α, α, 4-trimethyl-cyclohexanementamine, 1 part of formic acid, 3 parts of salicylamidophthalimide, 0.5 parts of tetrakis (3-( 3', 5'-di-tert-butyl-4-hydroxyphenyl) propionate) pentaerythritol ester, 100 parts of polyethylene resins were kneaded in a kneader at 115° C. to obtain catalyst masterbatch particles, and then the obtained catalyst masterbatch The particles are immersed in molten low-molecular-weight polyethylene with an average molecular weight of 2000, stirred for 30 seconds, then filtered, and the catalyst masterbatch particles are collected and dried to obtain catalyst masterbatch particles coated with low-molecular-weight polyethylene on the surface;

[0035] Then the above-mentioned catalyst masterbatch particles that have wrapped polyethylene with 100 parts of polyethylene resin, 5 parts of polypro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com