A kind of synthetic method of polycarboxylate water-reducer containing siloxyl group

A synthesis method and technology of siloxy group are applied in the synthesis field of polycarboxylate water reducing agent to achieve excellent retardation and plastic preservation effect, avoid condensation reaction, and avoid the effect of not being able to function effectively.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

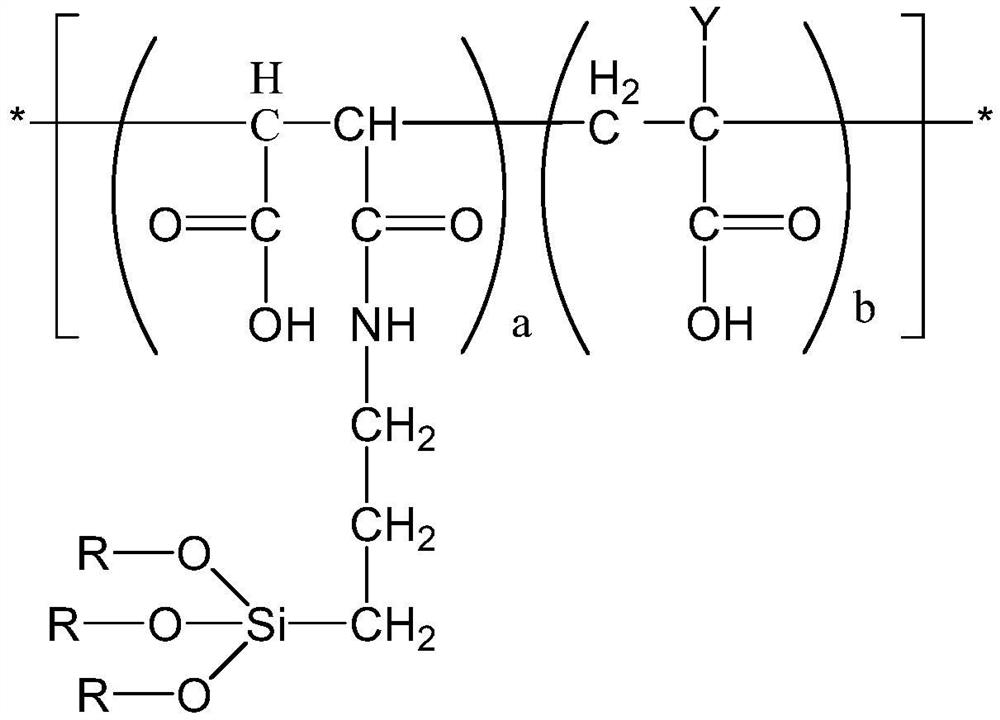

[0022]In a preferred embodiment, the method for synthesizing the polycarboxylic acid water reducing agent containing siloxy groups includes the following steps:

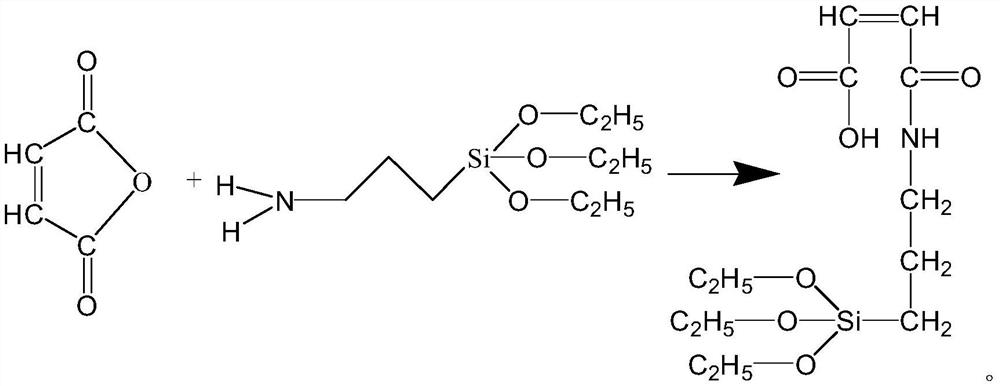

[0023]S1: Add dried maleic anhydride and dried silane coupling agent to the first reaction vessel, and mechanically stir for 30min~150min at a reaction temperature of 0℃~10℃, and the reaction will be complete to produce organic silicon. Polymer

[0024]S2: Add the silicone oligomer, organic solvent and initiator to the second reaction vessel, and add the unsaturated carboxylic acid monomer dropwise at a constant rate (after 1.5h to 3.5h), at 55°C to 85°C Under the reaction temperature, mechanical stirring reaction (total reaction time 2.5h-6h), add ethanol solution of sodium hydroxide to adjust the pH value to 7.0-8.5, after the organic solvent is evaporated under reduced pressure, the siloxy-containing Polycarboxylic acid water reducing agent.

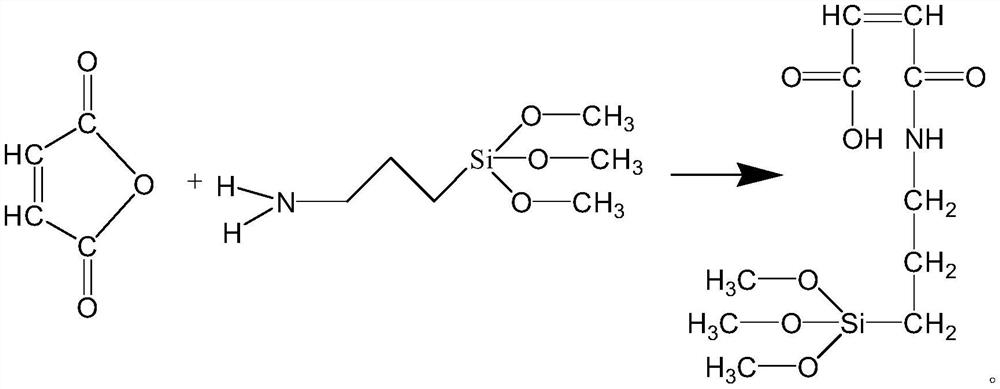

[0025]In a preferred embodiment, in S1, the silane coupling agent is γ-aminopropyl tri...

Embodiment 1

[0040]S1: Add 1000g of dried maleic anhydride and 2000g of dried γ-aminopropyltriethoxysilane to the first reaction vessel, and mechanically stir for 90 minutes at a reaction temperature of 5°C. The reaction is complete to produce Silicone oligomer;

[0041]S2: Add 250g of the organosilicon oligomer, 500ml of toluene and 10g of azobisisobutyronitrile to the second reaction vessel, and add 700g of acrylic acid dropwise at a constant rate (after 2.5h), at a reaction temperature of 65°C , Mechanical stirring reaction (total reaction time 3.5h), after the reaction is complete, add 20wt% sodium hydroxide ethanol solution to adjust the pH to 7.5, after the organic solvent is evaporated under reduced pressure, the polycarboxylic acid containing siloxy group is obtained. Liquid ①.

Embodiment 2

[0043]S1: Add 1000g of dried maleic anhydride and 1500g of dried γ-aminopropyltrimethoxysilane to the first reaction vessel, and mechanically stir for 60min at a reaction temperature of 8°C. The reaction is complete to produce organic Silicon oligomer;

[0044]S2: Add 200g of the silicone oligomer, 500ml of n-hexane and 15g of benzoyl peroxide to the second reaction vessel, and add 800g of methacrylic acid dropwise at a constant rate (after 3.5h), the reaction will be carried out at 75°C Under the temperature, mechanical stirring reaction (total reaction time 5.5h), after the reaction is complete, add 20wt% sodium hydroxide in ethanol to adjust the pH to 8.0, after the organic solvent is evaporated under reduced pressure, the polycarboxylate containing siloxy is obtained. Acid water reducing agent②.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com