A kind of synthetic method of retarding polycarboxylate superplasticizer

A technology of retarding polycarboxylic acid and its synthesis method, which is applied in the field of construction admixtures and can solve problems such as inability to fully utilize it

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] In a preferred embodiment, the synthetic method of the retarded polycarboxylate water reducer comprises the following steps:

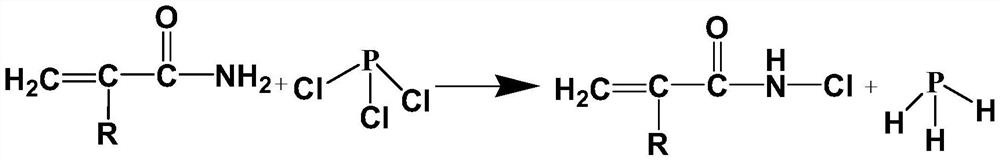

[0024] S1: Under the protection of nitrogen, add acrylamide or / and methacrylamide to the first reaction vessel, and add phosphorus trichloride, at a reaction temperature of 0°C to 10°C, stir mechanically, and react for 2 to 5 hours , for example according to the following reaction:

[0025]

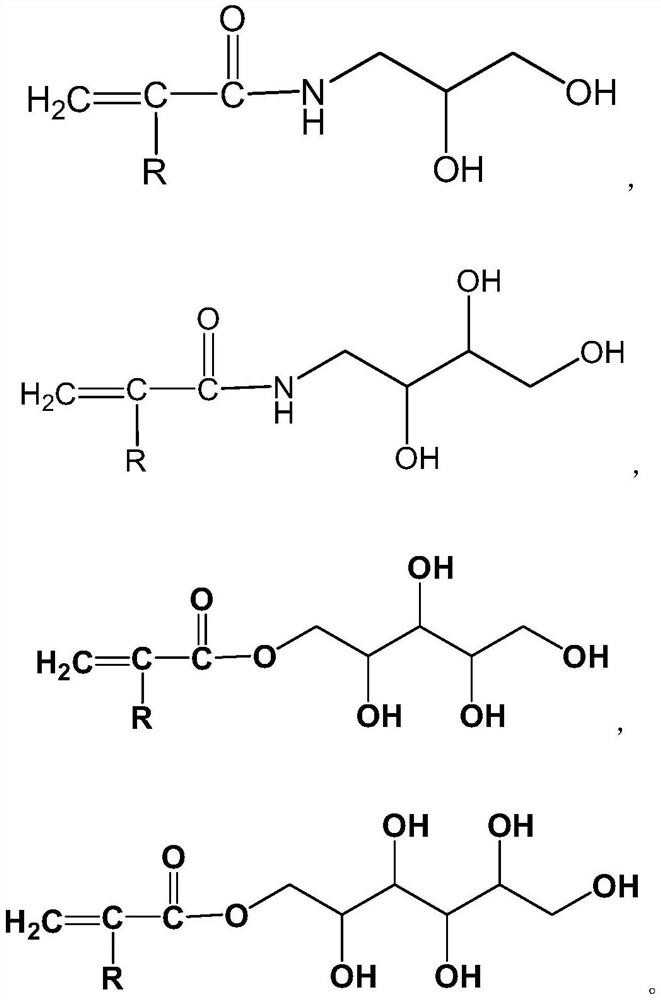

[0026] (R is H or methyl); then, add polyhydric alcohol and further react for 2 to 5 hours to generate intermediate A;

[0027] S2: Add the intermediate A, alkali metal alcoholate (as a catalyst), and ethylene oxide or / and propylene oxide to the second reaction vessel (pressure reaction vessel), and react at 160°C to 195°C Under the temperature and reaction pressure of 1.8Mpa~3.6Mpa, anionic ring-opening polymerization reaction is carried out for 4~7 hours to generate multi-branched polyether containing hydrolyzable functional groups; among them, interm...

Embodiment 1

[0040] S1: Under the protection of nitrogen, add 2000g of acrylamide and 2000g of phosphorus trichloride to the first reaction vessel, and stir mechanically at 5°C for 4 hours; then, add 2200g of glycerol for further reaction for 3.5 hours, to generate intermediate A;

[0041] S2: Add 1000g of the intermediate A, 20g of sodium ethoxide, and 20kg of ethylene oxide into the second reaction vessel (pressure reaction vessel), and perform anionic ring-opening polymerization at a reaction temperature of 180°C and a reaction pressure of 1.8Mpa React for 5.5 hours to generate a multi-branched polyether containing hydrolyzable functional groups;

[0042] S3: Add 2000g of the multi-branched polyether containing hydrolyzable functional groups, 220g of acrylic acid and 25g of sodium persulfate to the third reaction vessel; carry out free radical copolymerization reaction at a reaction temperature of 70°C for 4.5 hours, after the reaction is complete , adding 35 wt% sodium hydroxide aqueo...

Embodiment 2

[0044]S1: Under the protection of nitrogen, add 1800g of acrylamide and 2000g of phosphorus trichloride to the first reaction vessel, and stir it mechanically at 5°C for 4 hours; then, add 3200g of butylene glycol for further reaction for 3 hours, to generate intermediate A;

[0045] S2: Add 1000g of the intermediate A, 25g of sodium ethoxide, and 25kg of propylene oxide to the second reaction vessel (pressure reaction vessel), and carry out anionic ring-opening polymerization at a reaction temperature of 175°C and a reaction pressure of 2.6Mpa After 5 hours, a multi-branched polyether containing hydrolyzable functional groups was generated;

[0046] S3: Add 2000 g of the multi-branched polyether containing hydrolyzable functional groups, 280 g of methacrylic acid and 35 g of potassium persulfate to the third reaction vessel; carry out free radical copolymerization reaction at a reaction temperature of 75° C. for 5 hours, and react After completion, add 35wt% sodium hydroxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com