Motor driven worm gear transmission underground sleeve valve

A motor-driven, casing valve technology, applied in wellbore/well valve devices, wellbore/well parts, earthwork drilling and production, etc., can solve high-risk faults and other problems, achieve the effect of reducing fault sources and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

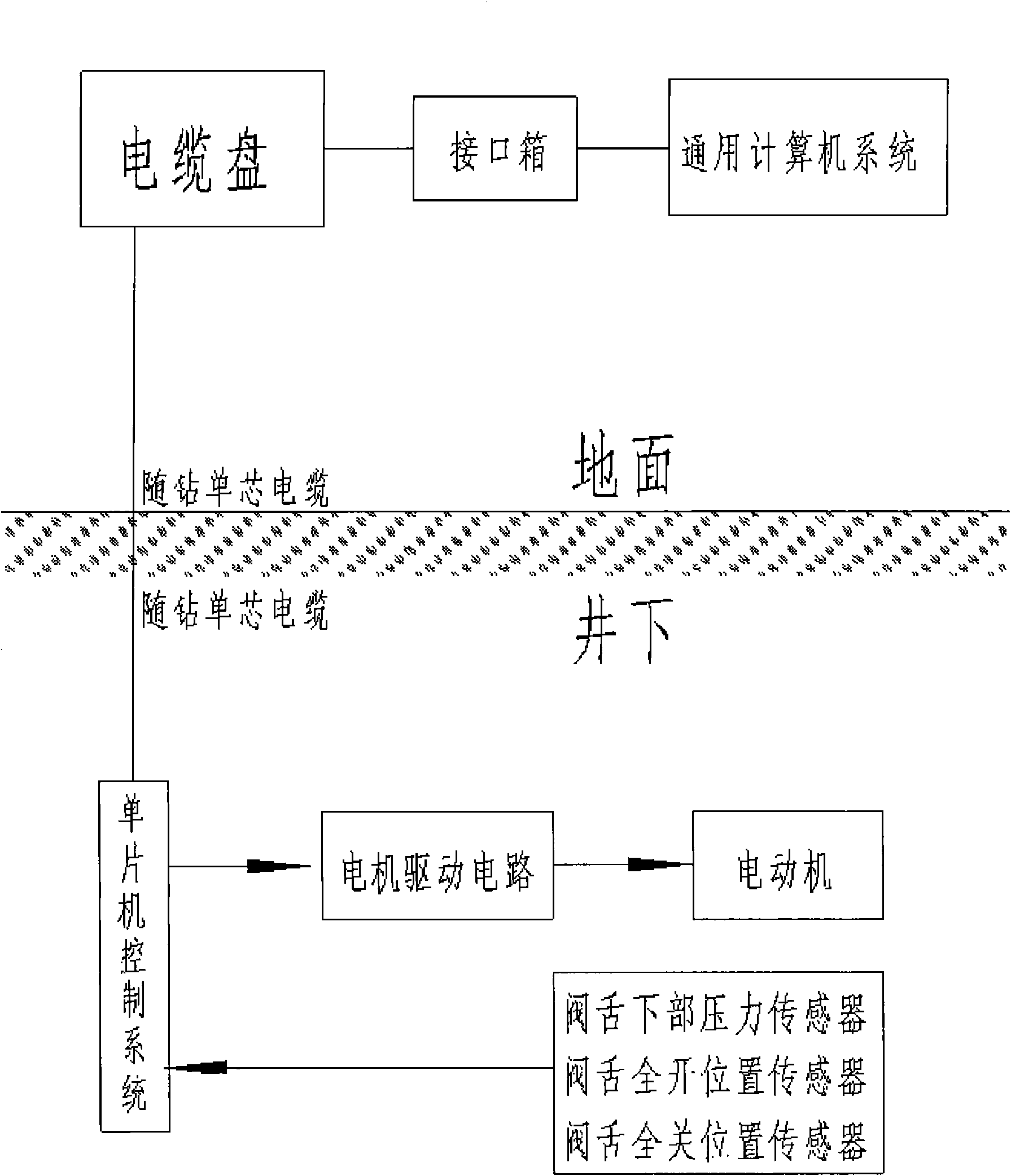

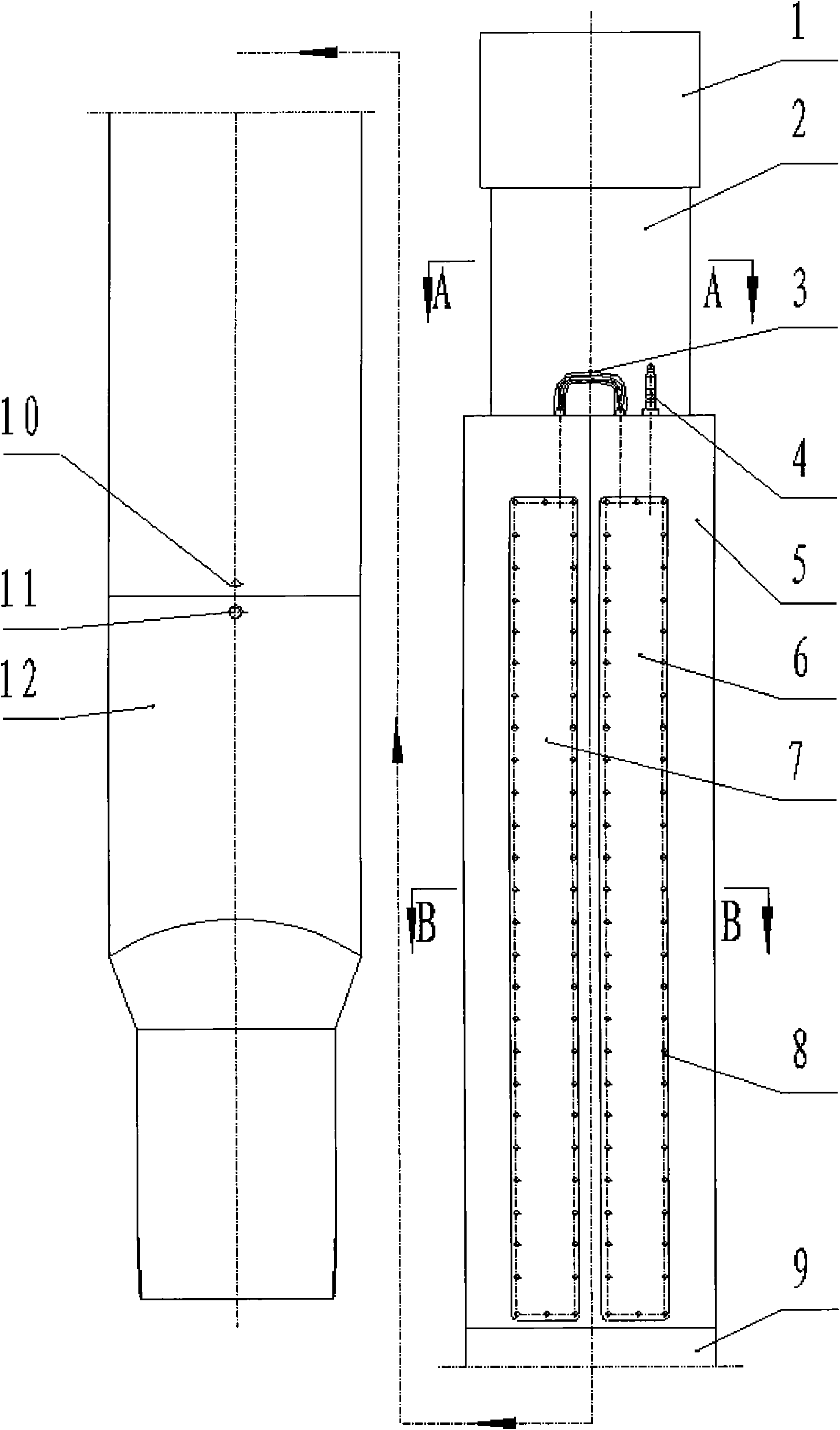

[0021] Such as figure 1 As shown, the switch action of the downhole casing valve tongue is all commanded by the ground computer through the keyboard or mouse, and the command signal is transmitted to the downhole single-chip control system through the interface box through the cable, and at the same time, the power is transmitted to the downhole system through the interface box. After receiving the control signal from the ground, the downhole single-chip microcomputer control system sends out a motor drive signal to control the positive and negative rotation of the motor. At the same time, the single-chip microcomputer control system regularly samples the parameter values of the pressure sensor, the valve tongue fully open position sensor and the valve tongue fully closed position sensor, and converts the parameter signals to the ground through the cable. This keeps the surface computer in the process of monitoring the downhole casing valve status in real time.

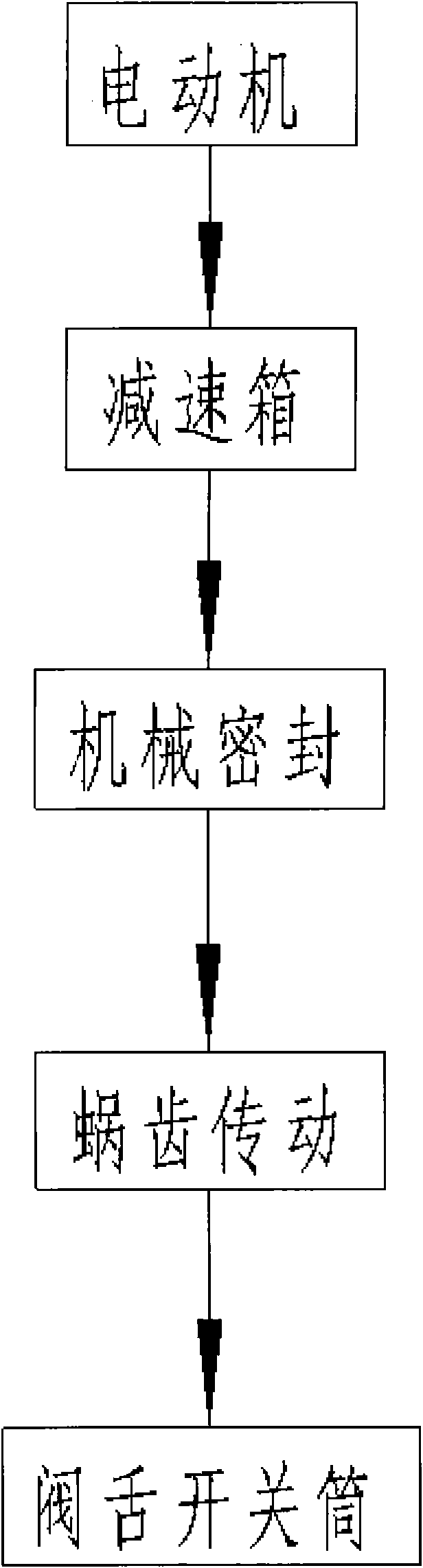

[0022] Suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com